Feedstuff bag stacking device and method

A bag stacking and feed bag technology, applied in the field of feed bag stacking device, can solve the problems of complex structure, long time required, affecting the production progress of the factory, etc., and achieves low cost, simple and clear connection relationship, and convenient maintenance and manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

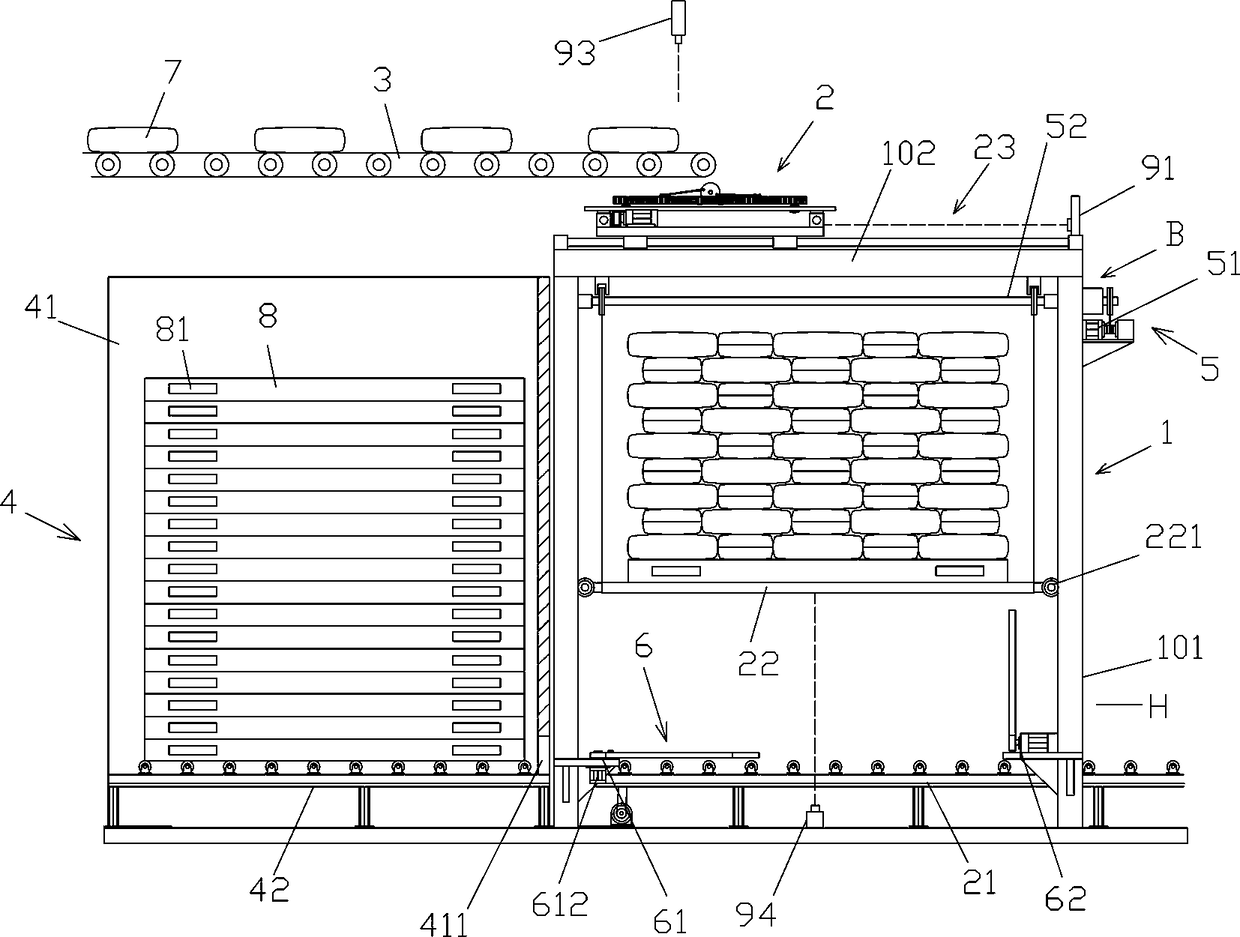

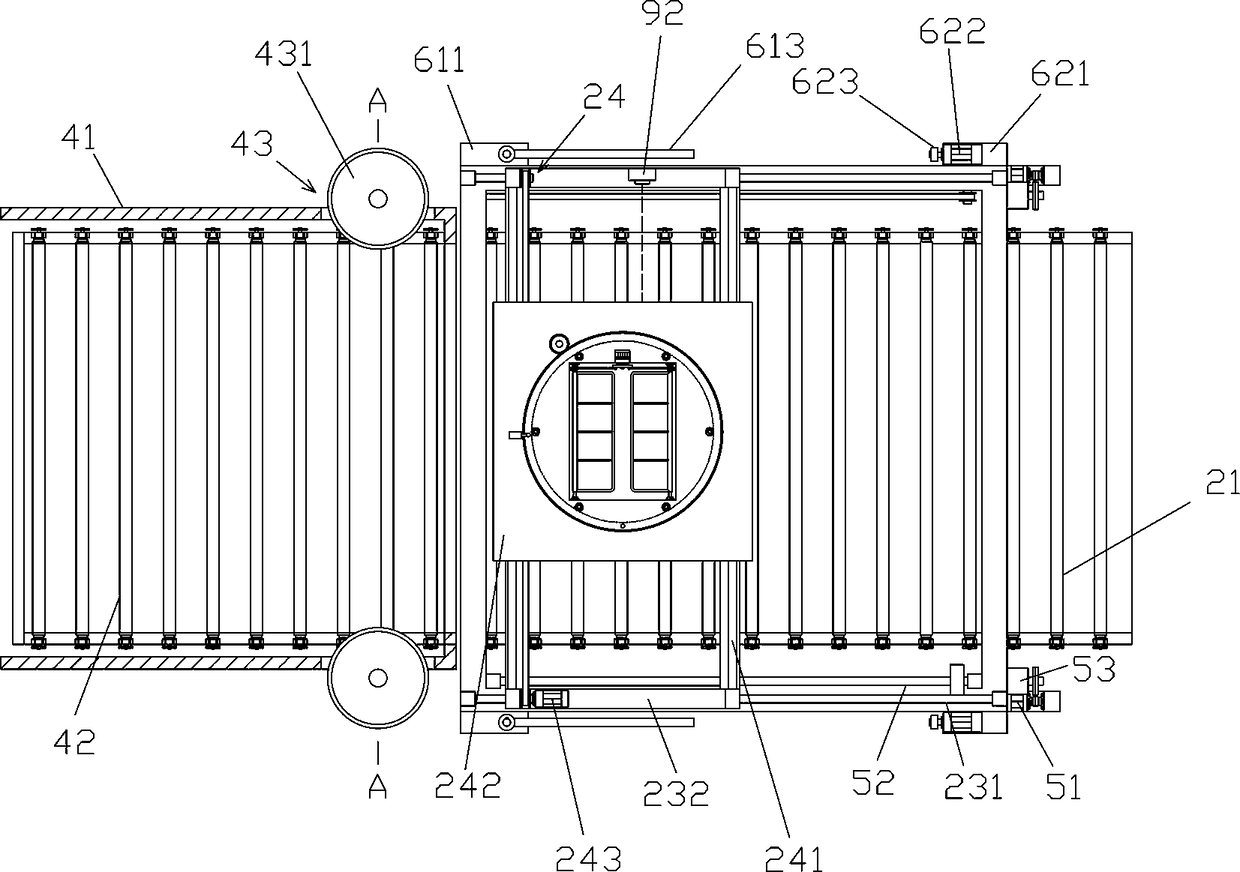

[0048] Such as figure 1 with 2 Shown, a kind of feed package palletizing device comprises disk storage device 4, palletizing mechanism and belt conveyor 3, and storage disk device 4 is arranged on one side of palletizing mechanism, and belt conveyor 3 is arranged on the top of palletizing mechanism,

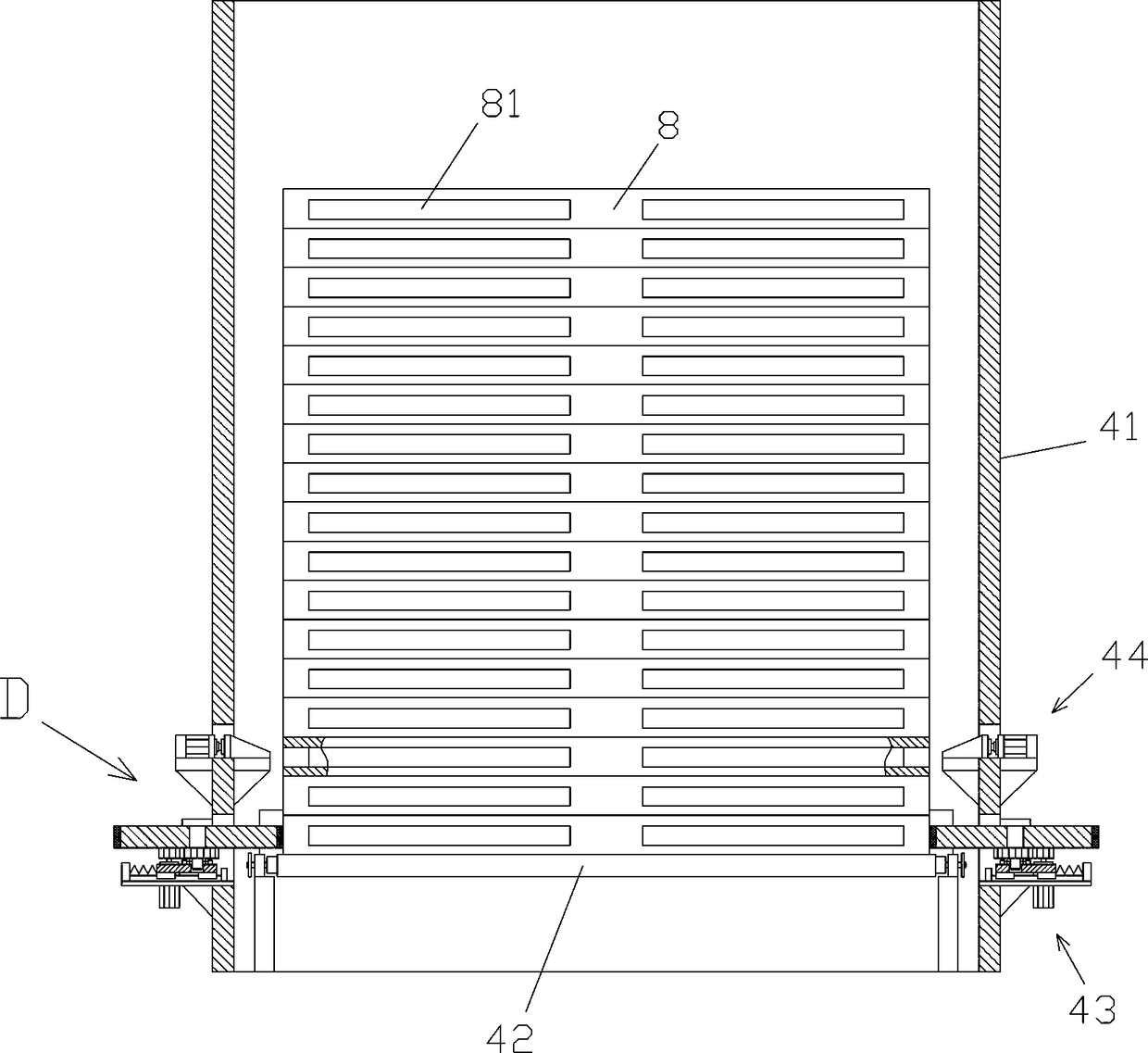

[0049] Disk storage device 4: including a conveying platform 42, three guard plates 41 are arranged outside the conveying platform 42, and a space for storing the tray 8 is formed by each guard plate 41 and the periphery of the conveying platform 42, and a space close to the palletizing mechanism The lower end of the guard plate 41 is provided with a first opening 411. After the forklift has placed a plurality of pallets 8 stacked on the conveying platform 42 through the opening on one side of the space, the conveying platform 42 is started to convey the lowermost pallet 8 to the yard. In the palletizing mechanism, to realize the automatic loading of the pallet 8, to ensure that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com