Electronic building module and manufacturing method thereof

An electronic and block technology, applied in the direction of circuits, electrical components, circuit/collector parts, etc., can solve the problems of increased proportion of defective products, complex production process, insufficient bonding strength of circuit connectors and circuit boards, etc. To achieve the effect of improving the fixing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

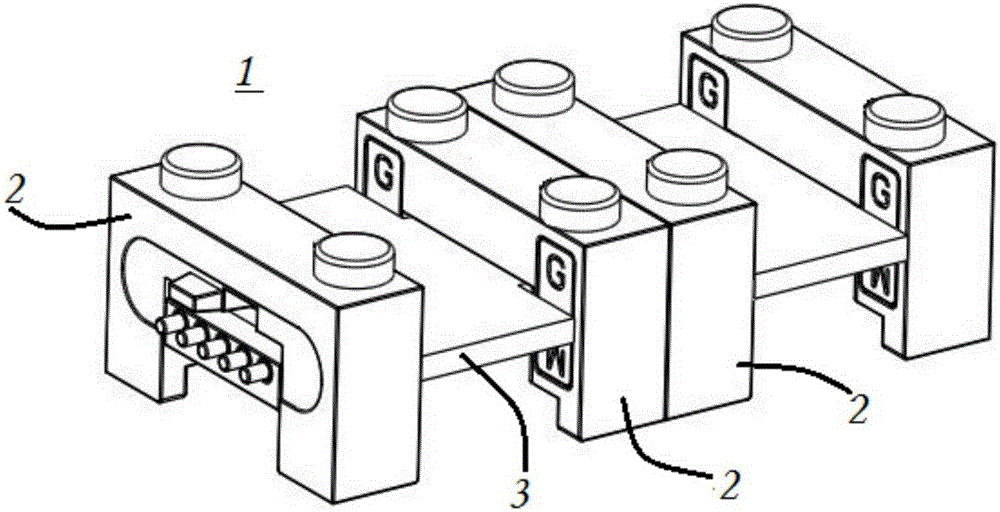

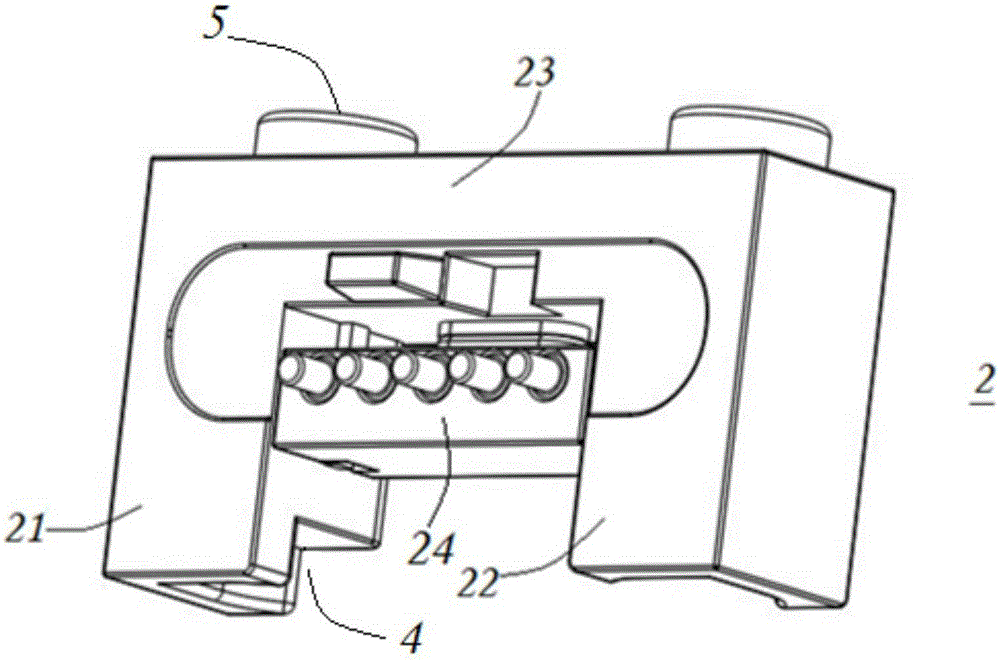

[0033] figure 1 An example of an electronic building block of the present embodiment is shown. The electronic building blocks realize different functions according to the arrangement of their circuits and connection structures. Including but not limited to: power supply module, the module provides power for other modules or electrical components through batteries or external power supply; The device and its driving circuit provide power; the sensor module obtains and sends signals by setting the sensor; the logic control module realizes various controls by setting the logic circuit or providing a programmable controller; the display module displays information by setting the display ; Communication module, providing wired or wireless communication. Each electronic building block completes the predetermined function, and realizes various electronic building blocks and other mechanical or circuit structures through assembly to form the required works.

[0034] Such as figure...

Embodiment 2

[0067] This specific embodiment also provides a method for making an electronic building block. The method was used to fabricate the electronic building blocks described in Example 1.

[0068] The method includes;

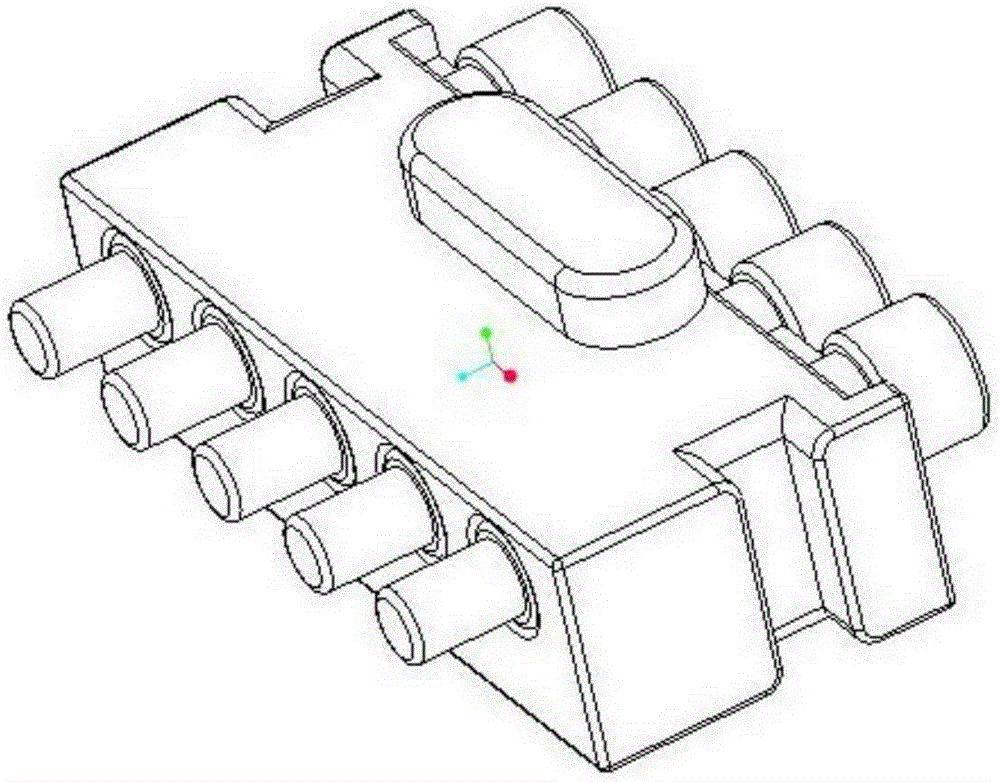

[0069] Step 1, connect the fixing piece with the circuit unit.

[0070] Such as Figure 11 As shown, the connection includes passing the mounting boss of the fixing member through the corresponding hole in the circuit unit. Preferably, the method further includes passing the terminal through the through hole in the fixing member and electrically connecting the terminal to the terminal in the circuit unit.

[0071] Further preferably, a plurality of the fixing parts are installed and fixed by a strip; a plurality of the circuit units are assembled into a panel; the fixing parts on the strip are removed one by one by an automatic placement machine and then installed on the on the imposition. In this way, machinery and equipment can be used for production, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com