Diaper bottom film conveying and blowing device

A technology of blowing device and diapers, which is applied in transportation and packaging, medical science, clothing, etc., can solve the problems of not being able to effectively ensure the flatness of the bottom film conveying, unreasonable design of the conveying blowing device, and affecting the processing quality, etc., to achieve Reasonable design, improved processing quality, and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

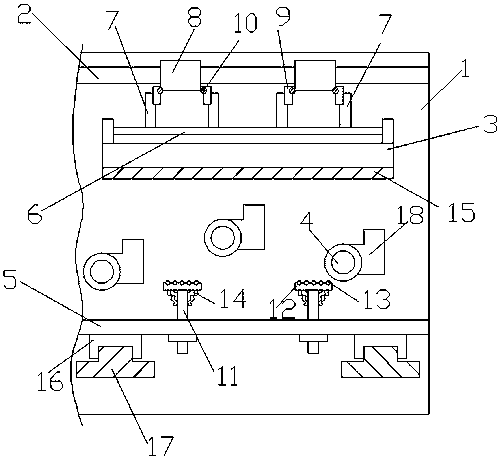

[0013] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0014] Such as figure 1 As shown: a diaper bottom film conveying and blowing device of this embodiment, including a support frame 2, a fan plate 3, several conveying shafts 4 and a supporting plate arranged sequentially in the operating cabinet 1 from top to bottom 5. One end of the conveying shaft 4 is connected and fixed to the regulating plate 18 .

[0015] The bottom of the supporting plate 5 is connected and fixed with the receiving block 17 in the operating cabinet 1 through the clamping plate 16 ; each fan plate 3 is provided with an illuminating lamp 15 .

[0016] The top of each fan plate 3 is connected to a support rod 6, wherein a plurality of slide rods 7 are slidably arranged on the support rod 6, and the top of each slide rod 7 is fixed on the support frame 2 through an assembly, The assembly includes a sleeve 8 and a rotating plate 9, the sleeve ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap