Turning method for duplex stainless steel P-type block

A duplex stainless steel, total section technology, applied in ship parts, ships, load hanging components, etc., can solve the problem of the difficulty of turning over the P-type total section, and achieve the effect of maintaining mechanical stability and preventing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

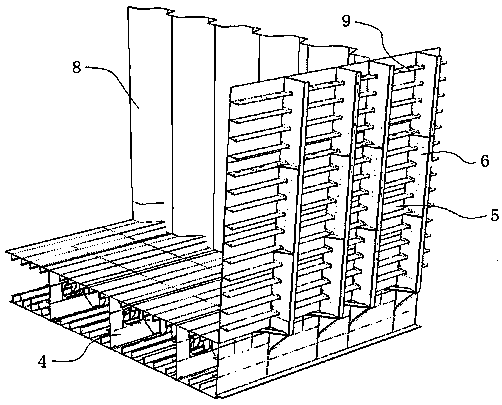

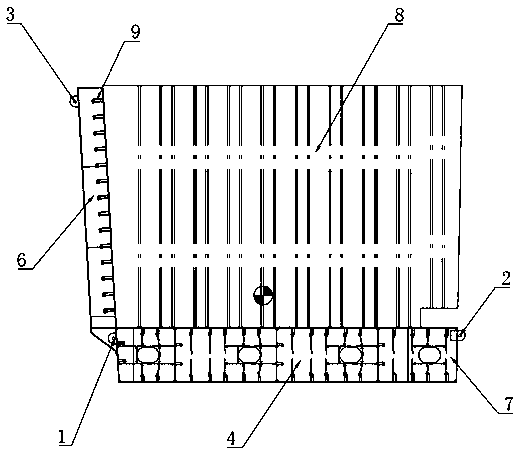

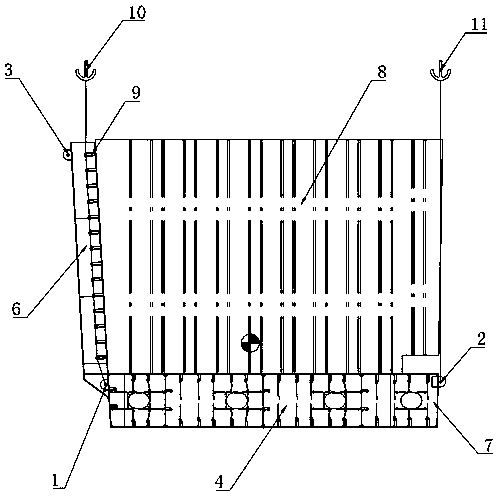

[0024] Embodiment: a method for turning over the P-type total section of duplex stainless steel, comprising the following steps:

[0025] Step 1. Arrange four turn over main hooks 1, four turn over auxiliary hooks 2 and two translation main hooks 3 on the P-type general section, and the four turn over main hooks 1 are all arranged on the deck of the side section 4, The four turn over main hooks 1 correspond to the four T rows 6 on the deck section 5 respectively, and the four turn over main hooks 1 are on the same horizontal line, and the four turn over auxiliary hooks 2 are arranged on the side On the rib plate 7 of the segment 4, and two turned over auxiliary hooks 2 are on one side of the transverse compartment segment 8, and the other two turned over auxiliary hooks 2 are on the other side of the transverse compartment segment 8, the two The translational main hooks 3 are respectively arranged on the two T rows 6 closest to the transverse compartment section 8 on the deck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com