Coaxial cable and method of manufacturing a coaxial cable

A coaxial cable and cable technology, applied in the field of manufacturing coaxial cables, can solve the problems of expensive resources and low penetration depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

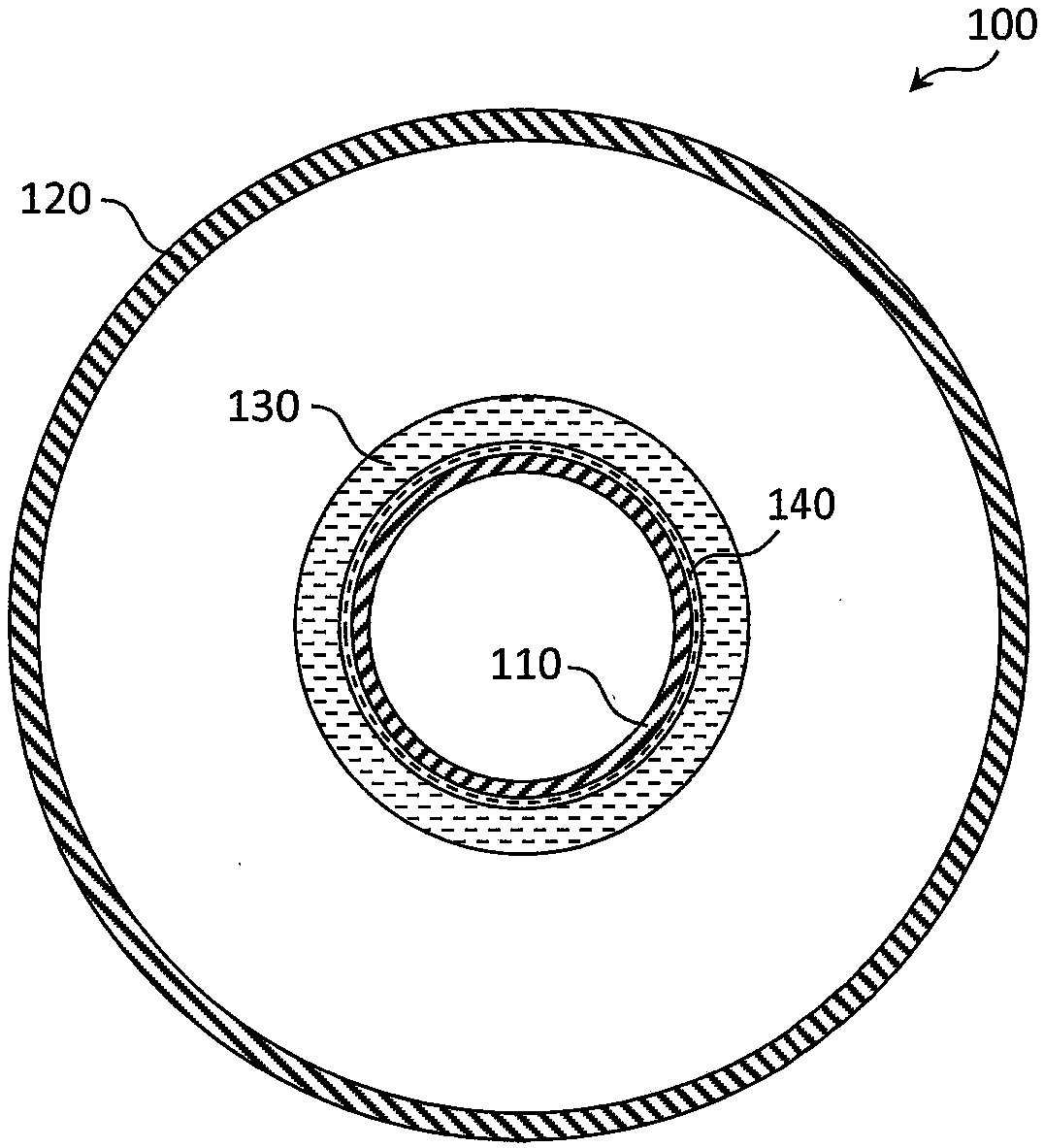

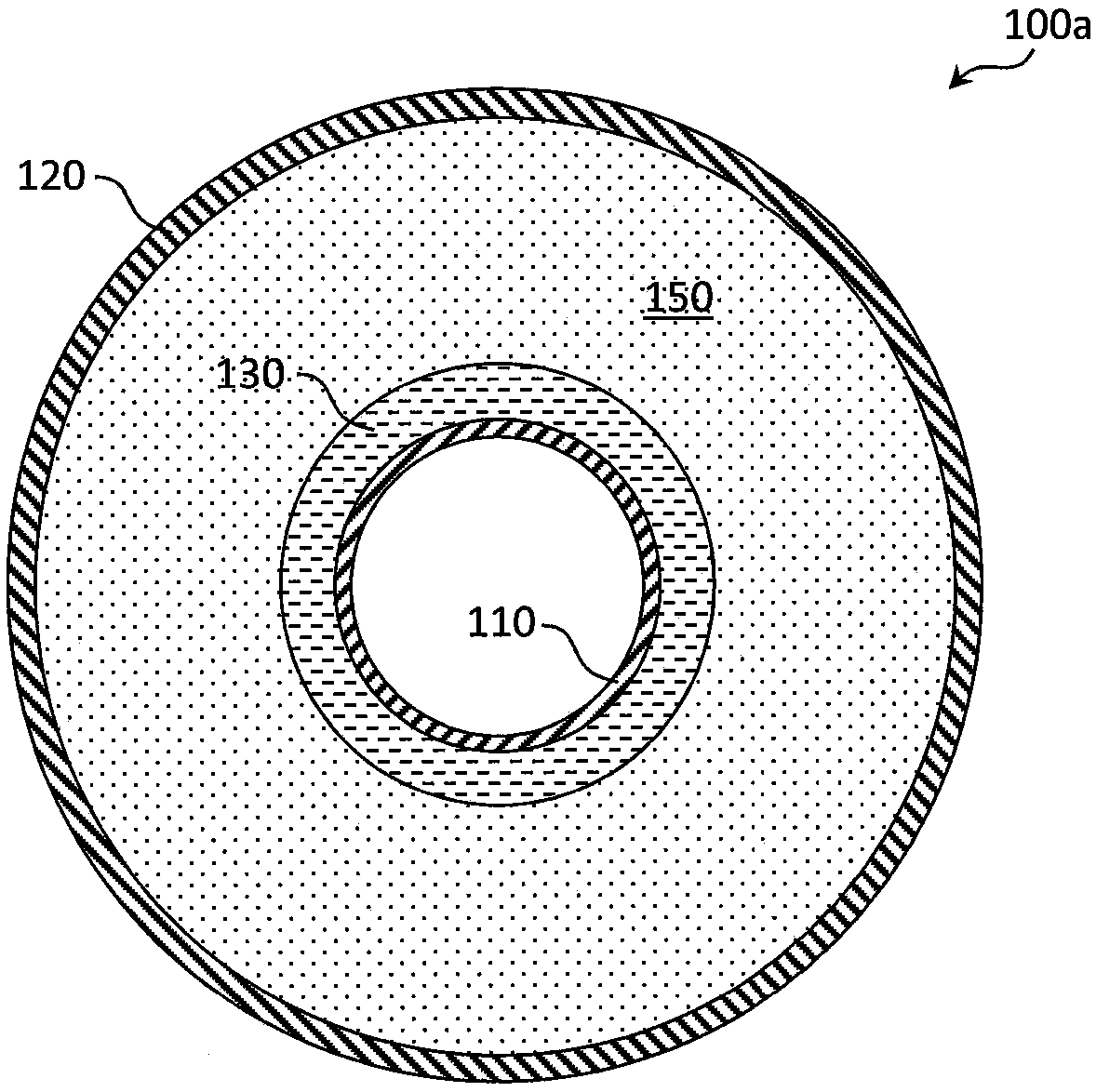

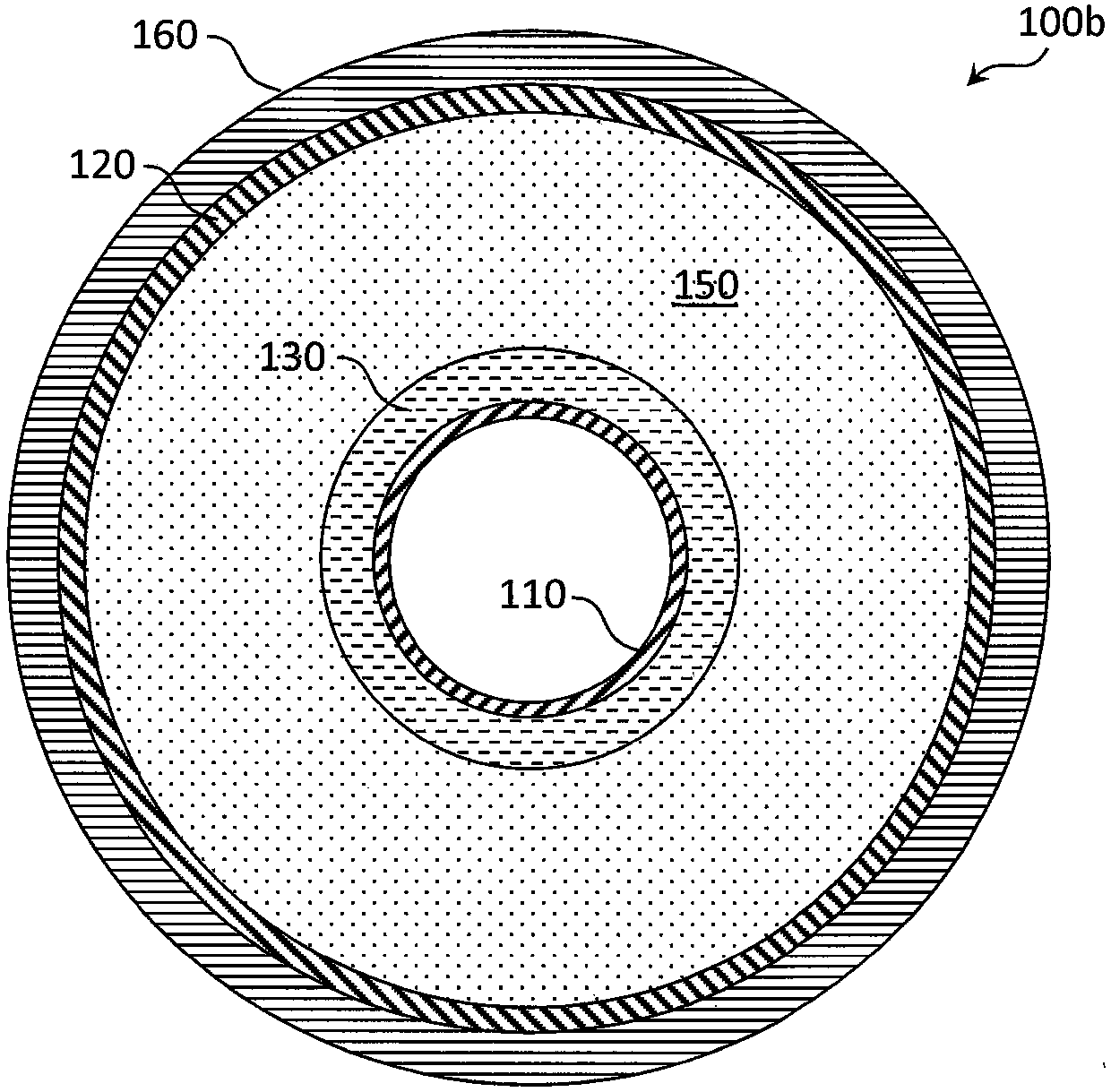

[0031] figure 1 A cross-sectional view of coaxial cable 100 is schematically depicted, according to one embodiment. The cable 100 includes an inner conductor 110 and an outer conductor 120 arranged radially outside the inner conductor 110 . The inner conductor 110 and / or the outer conductor 120 may comprise a copper material or may be made of a copper material, in particular pure copper.

[0032] According to the principle of an embodiment, at least one stress absorbing element 130 for absorbing mechanical stress is arranged radially between the inner conductor 110 and the outer conductor 120 . That is, at least one stress absorbing element 130 is placed radially outside the inner conductor 110 and radially inside the outer conductor 120 .

[0033] At least one stress absorbing element 130 may absorb mechanical stress applied to the cable 100 , thereby protecting the inner conductor 110 from excessive mechanical stress that would lead to destruction of the inner conductor 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com