A high-efficiency electric dehydrator

An electric dehydrator and high-efficiency technology, applied in the direction of electricity/magnetic dehydration/demulsification, etc., can solve the problem of rare electric dehydrator, and achieve the effect of increasing coalescence rate, dehydration efficiency, and processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

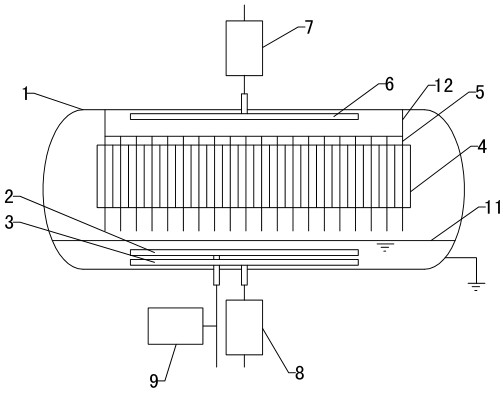

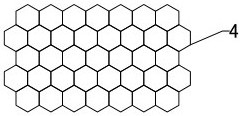

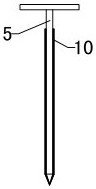

[0021] Figure 1~3 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~3 The present invention will be further described.

[0022] Refer to attached Figure 1~3 : A high-efficiency electric dehydrator, comprising an electric dehydrator housing 1 and an oil inlet pipe 2, a water outlet pipe 3 and an oil outlet pipe 6 installed in the electric dehydrator housing 1, the oil inlet pipe 2 and the water outlet pipe 3 are arranged on the electric dehydrator shell The lower part of the body 1, the oil outlet pipe 6 is arranged on the upper part of the electric dehydrator housing 1, the inlet of the oil inlet pipe 2 extends out of the electric dehydrator housing 1 and is connected to the reciprocating piston pump 9; the electric dehydrator housing 1 is provided with electrodes and The suspended needle grounding electrode 5 vertically passes through the flow channel in the electrode, and the lower side of the electric dehydrator housing 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com