A transmission mechanism for the handle outside the cabin door

A technology of a transmission mechanism and an outer handle, which is applied in the field of the mechanism that realizes the outer handle of the cabin door from inside to outside, can solve the problems that the transmission of two vertical shafts cannot be realized, and the layout and design of the cabin door mechanism are limited, so as to achieve flexible mechanism form, The effect of small rolling friction and increased transmission angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

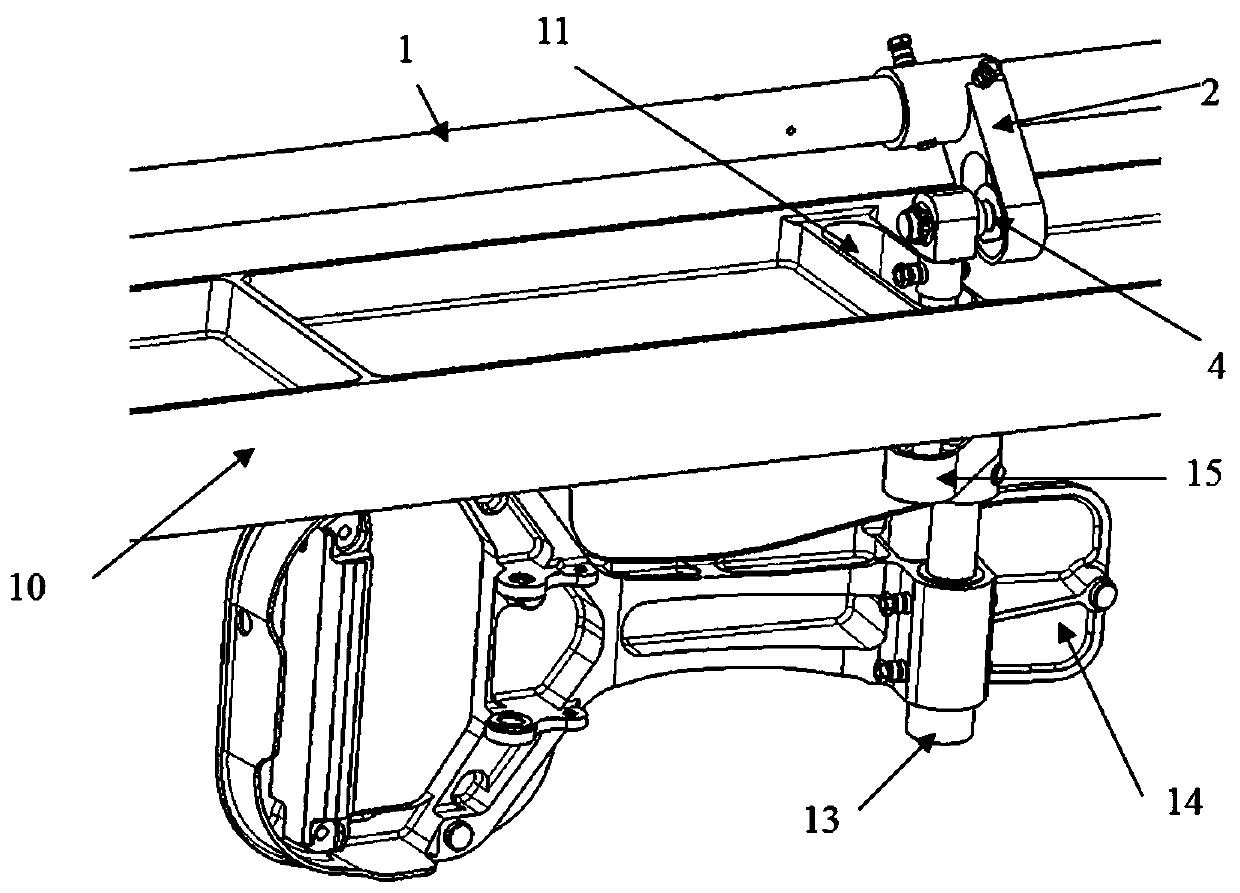

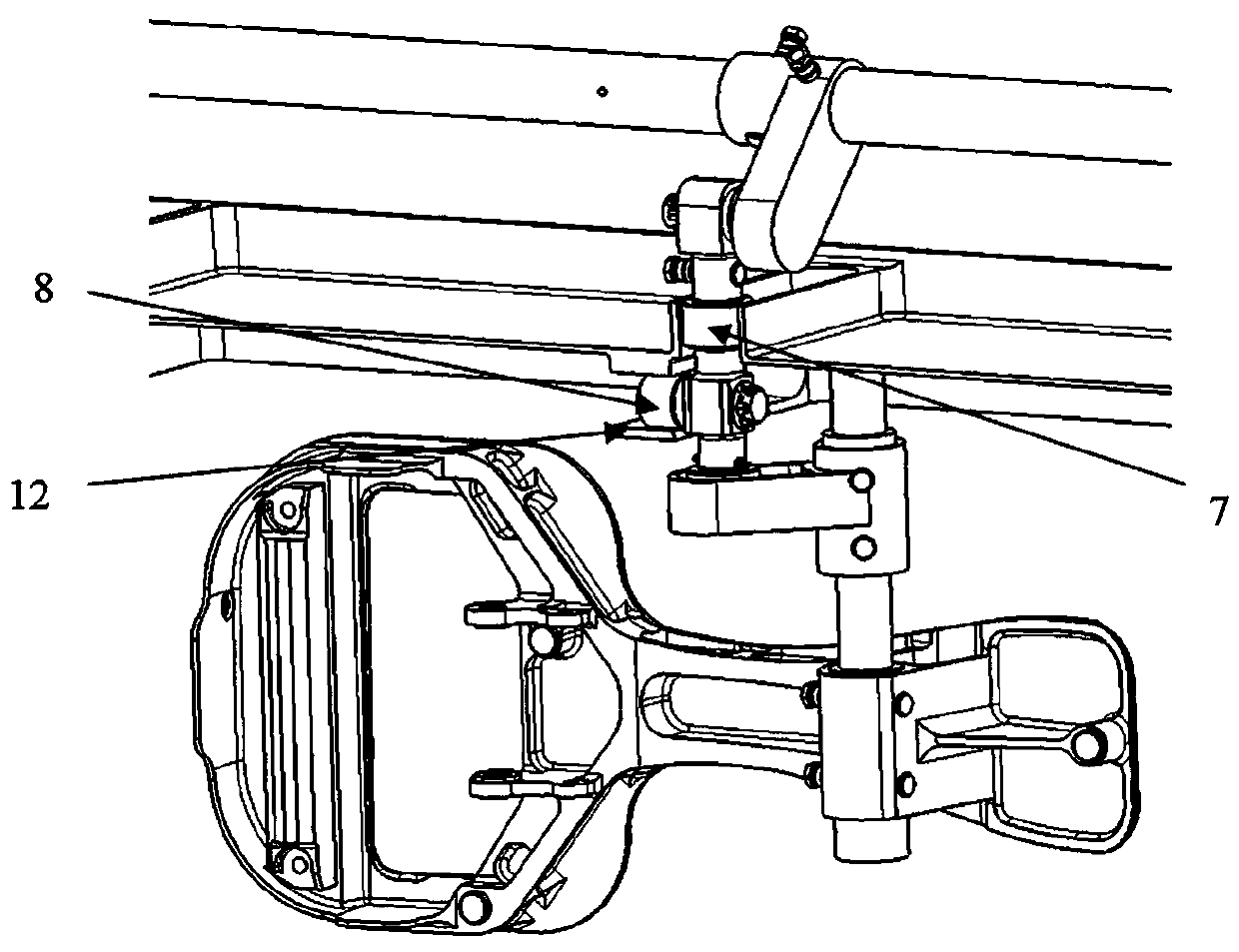

[0021] like figure 1 and figure 2 As shown, a transmission mechanism for the outer handle of the cabin door includes a lock shaft 1, a hatch beam structure 10 and an outer handle 14. The outer handle 14 is connected to the outer handle shaft 13, and the axis of the outer handle shaft 13 is connected to the axis of the lock shaft 1. Arranged vertically; the upper end of the outer handle shaft 13 is connected to the lower crank 15, and one end of the lower crank 15 is the outer handle shaft 13 as a rotating shaft, and the other end of the lower crank 15 is connected to a linkage rod mechanism, and the linkage rod mechanism passes through the door beam structure 10. The elongated groove 11 is connected with the upper crank 2 provided on the lock shaft 1 behind.

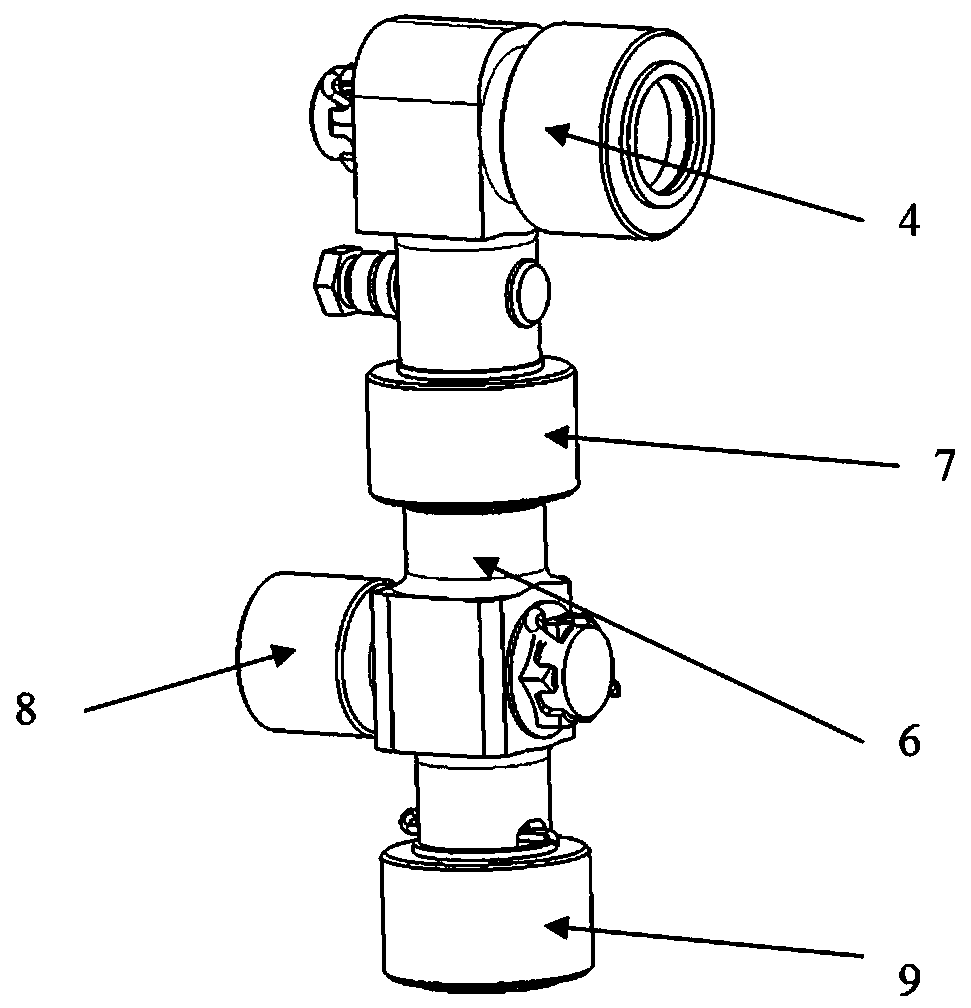

[0022] like image 3 As shown, the specific structure of the linkage mechanism is as follows: on the connecting rod 6, the lower crank roller 9, the upper limit roller 7 and the upper crank roller 4 are sequentially c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com