A cylinder brake transmission device

A technology of transmission and braking devices, which is applied in the direction of valve devices, engine components, machines/engines, etc., can solve the problems of knocking sound caused by movement, so as to improve the quality of the engine, prevent rapid rebound, prevent friction damage and The effect of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

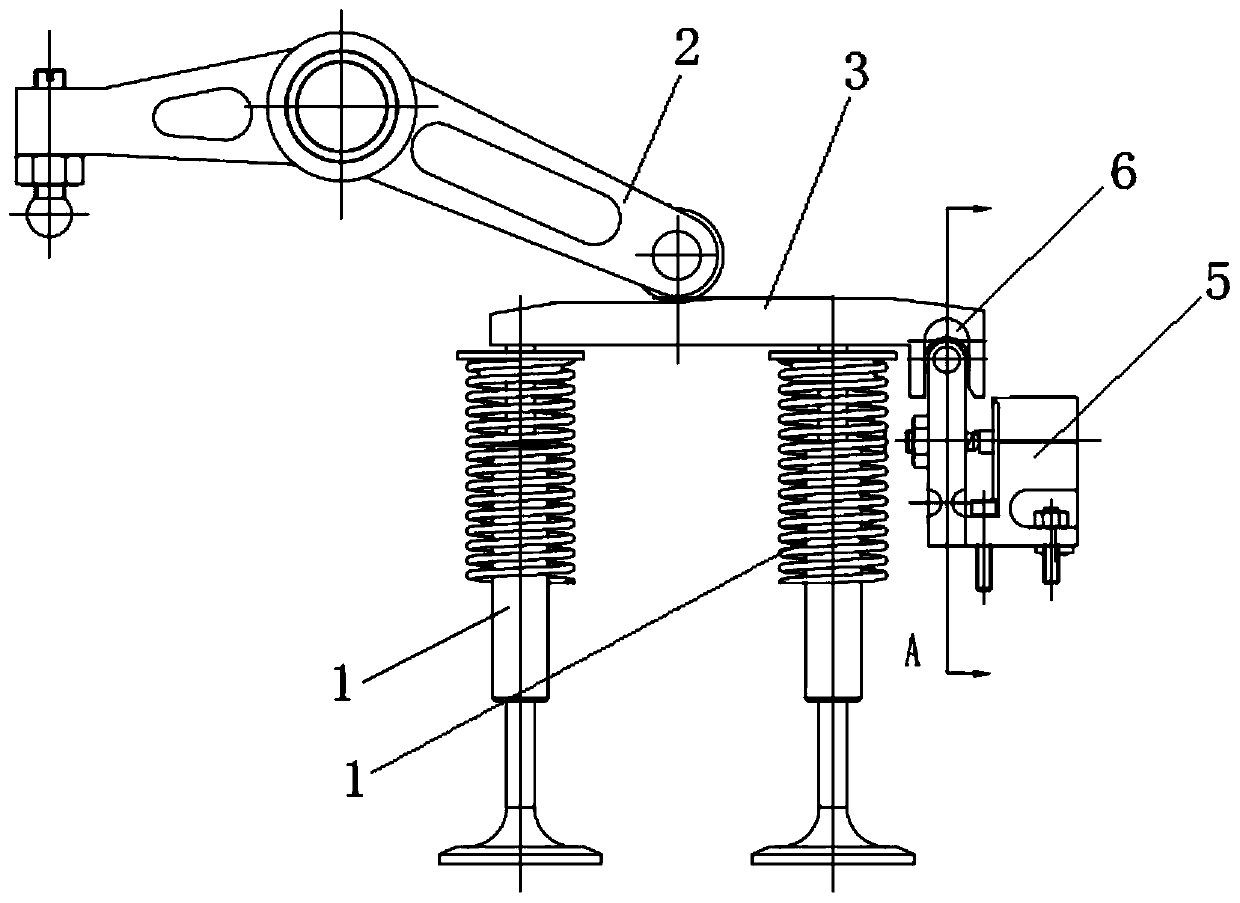

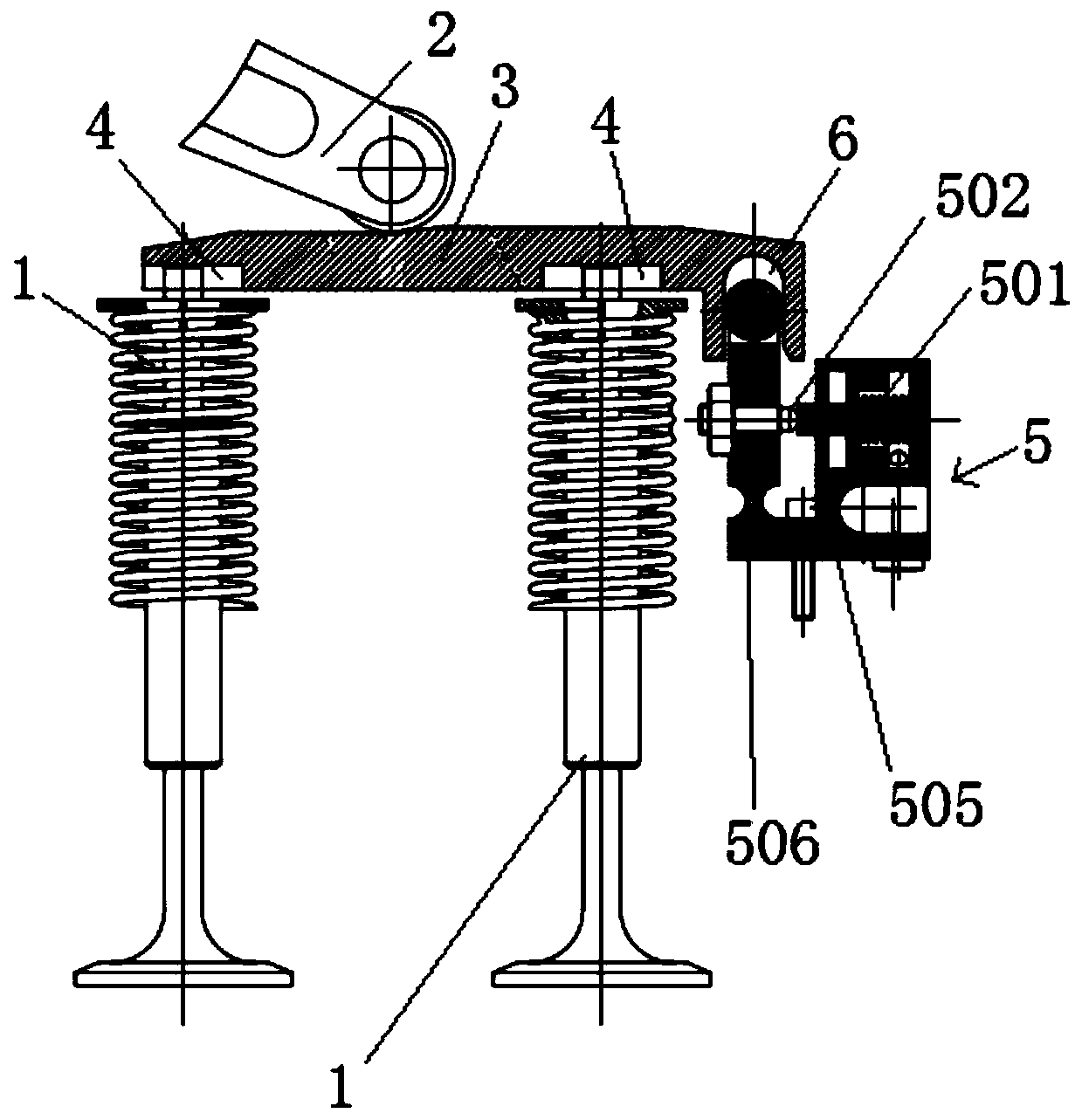

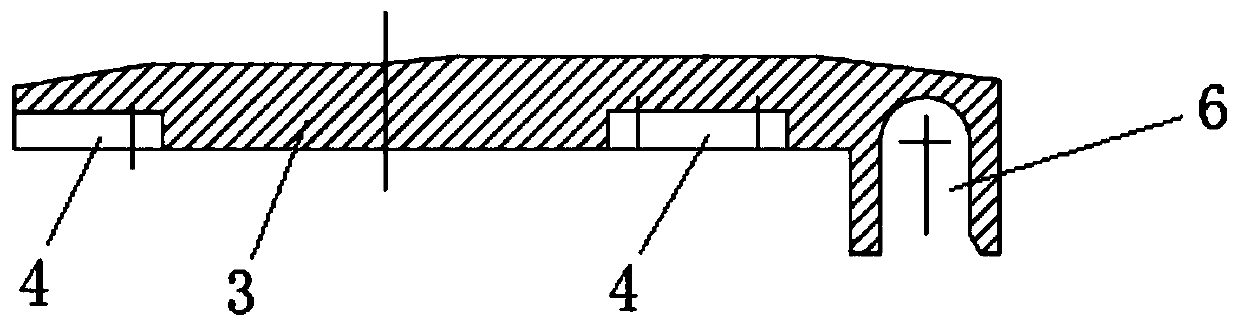

[0030] Such as Figure 1-8 As shown, an in-cylinder braking transmission device includes at least two valves 1 arranged side by side and a rocker device 2 for squeezing the valves 1, and a valve 1 and a rocker device 2 are provided between the valves 1 and the rocker device 2 to abut against them. And the valve bridge 3 that can move along the axis of the valve 1, the valve bridge 3 is provided with a guide transverse groove 4 extending perpendicular to the axis of the valve 1, and also includes a valve bridge 3 that can drive the valve bridge 3 along the direction perpendicular to the axis of the valve 1 The moving transverse braking device 5, the valve bridge 3 is provided with an axial guide groove 6 that is compatible with the transverse braking device 5; the rocker device 2 squeezes the valve bridge 3, and two or more than two The valve 1 is squeezed in the axial direction to open the valve 1, and when the valve bridge 3 is squeezed or knocked by the rocker device 2, the ...

Embodiment 2

[0043] The structure of the in-cylinder braking transmission device in this embodiment is basically the same as that of Embodiment 1, the difference is that, as attached Figure 9-10 As shown, the lateral braking device 5 in the first embodiment is adapted to one end of the valve bridge 3, and the lateral braking device 5 in the present embodiment is adapted to the middle part of the valve bridge 3; and the present embodiment Among them, the rotating shaft 507 of the lateral braking device 5 is extended outward, and the guide rollers 508 are arranged on the outside of the base 505, which facilitates the arrangement of the lateral braking device 5 and reduces the occupation of lateral space, so that the lateral braking device 5 can be arranged on Between the two valves 1, the structure is compact, and there is no need to modify the transitional structure, only the length of the rotating shaft 507 needs to be extended.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com