Rolling bearing having superthin wall

A rolling bearing, ultra-thin-wall technology, applied to bearing components, shafts and bearings, mechanical equipment, etc., to reduce friction sound or other abnormal sounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation, structure, features and functions of the ultra-thin-walled rolling bearing according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

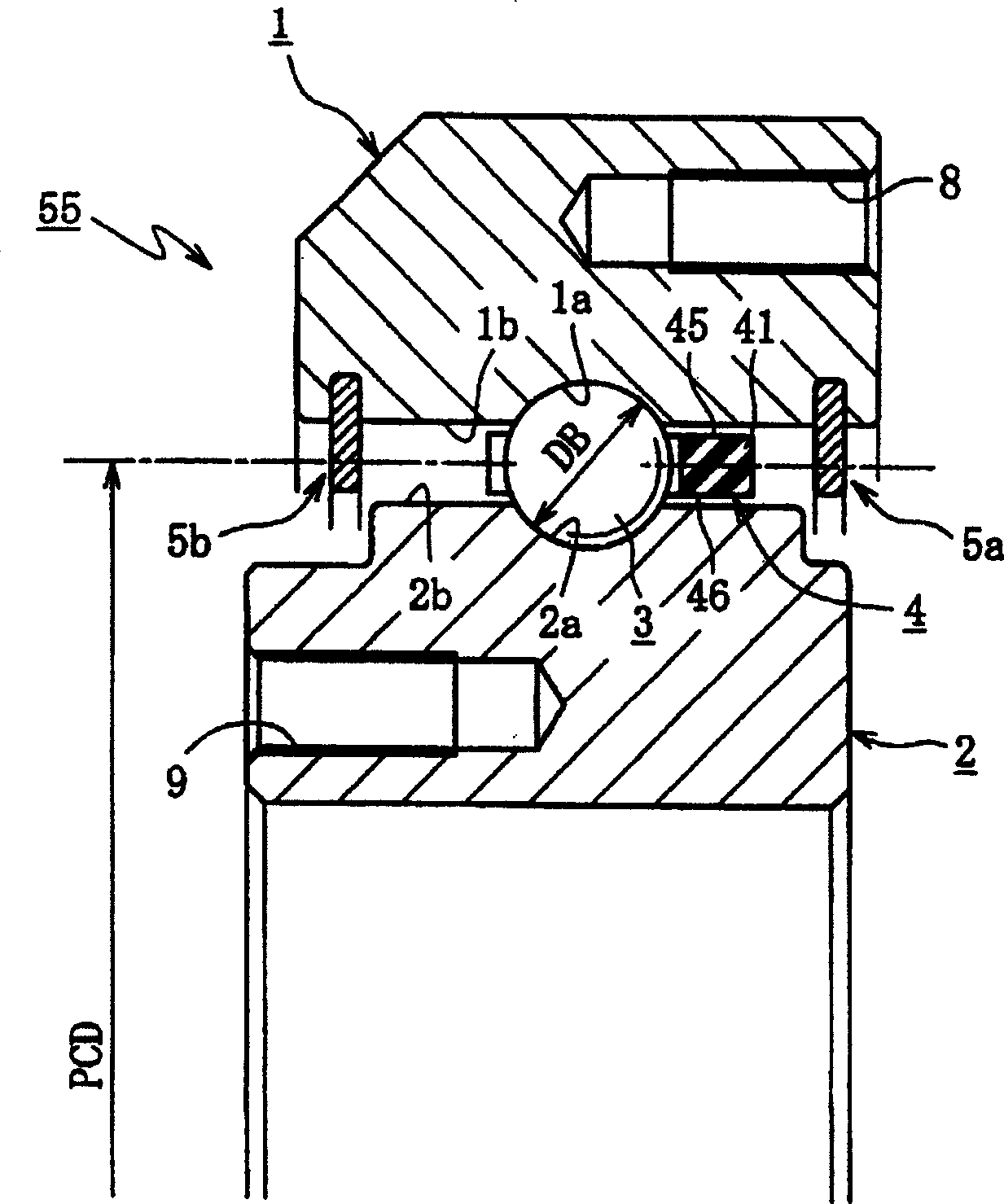

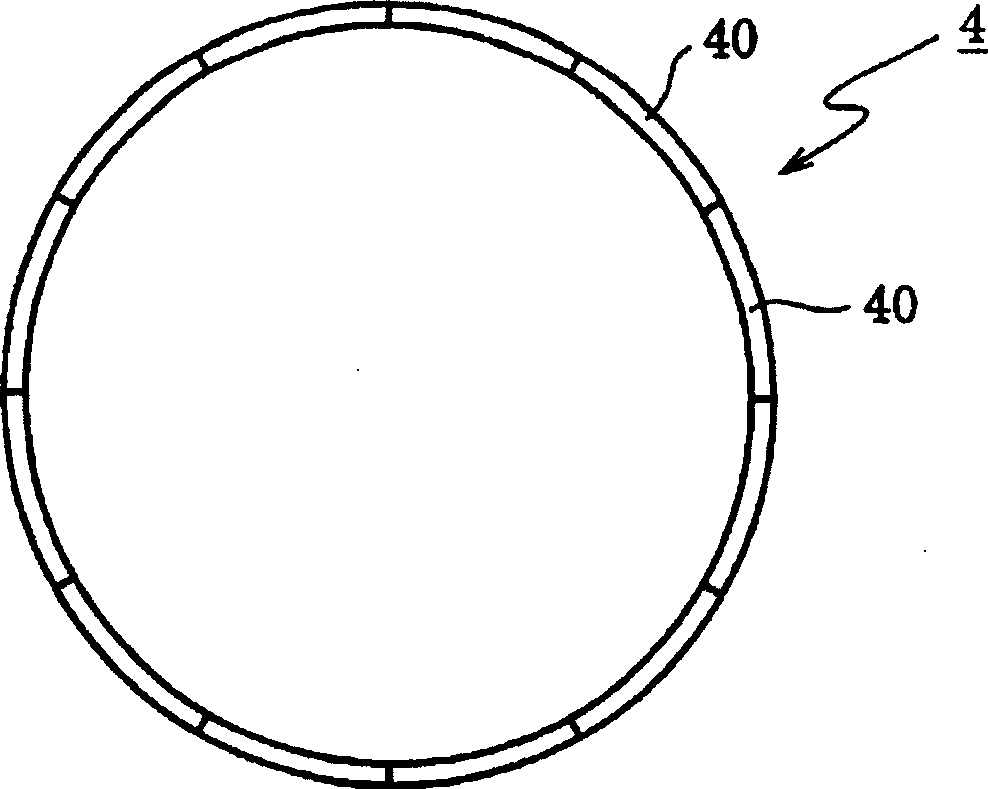

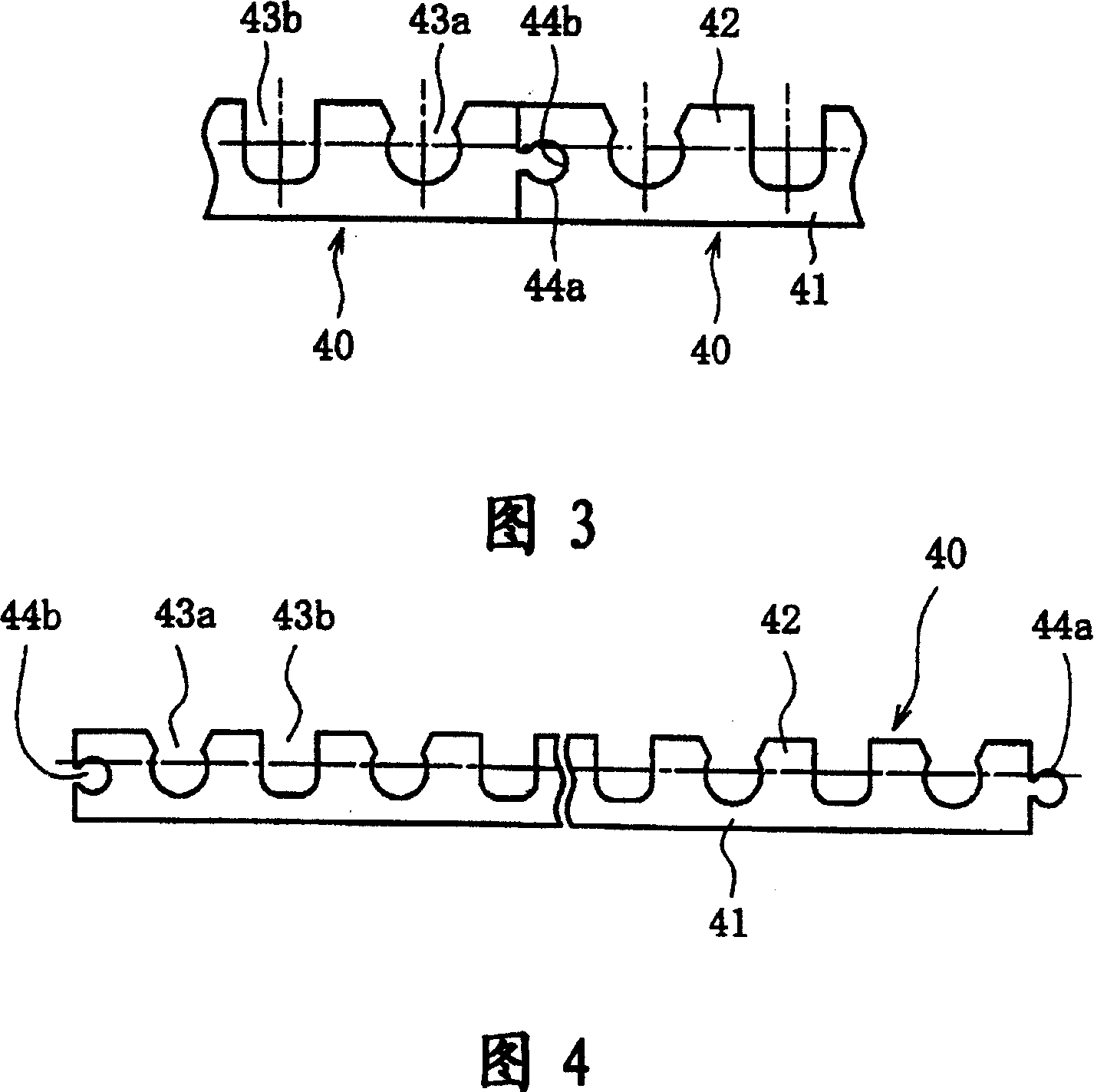

[0048] see figure 1 Shown is a schematic cross-sectional view of a rolling bearing 55 with ultra-thin walls used in CT scanning equipment. The rolling bearing 55 with ultra-thin wall of the preferred embodiment of the present invention comprises: an annular outer ring 1, an inner ring 2 concentrically arranged on the inner peripheral side of the outer ring 1, a plurality of rolling elements or balls 3 (in In this case, the balls 3 are rotatably disposed between the raceway surface 1a of the outer ring 1 and the raceway surface 2a of the inner ring 2), a cage for keeping these balls 3 positioned at equal intervals on the circumference 4 and seals 5a, 5b for sealing openings provided at opposite ends of the bearing.

[0049] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com