Woren fabric for toothed belt

A toothed belt and fabric technology, which is applied in the field of fabrics for toothed belts, can solve the problems of unavailable twill fabrics, poor adhesion between fabrics and rubber, and irregular fabric twill lines, so as to save the space in the engine and save the original cost. The effect of small reduction in yarn strength and excellent elongation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

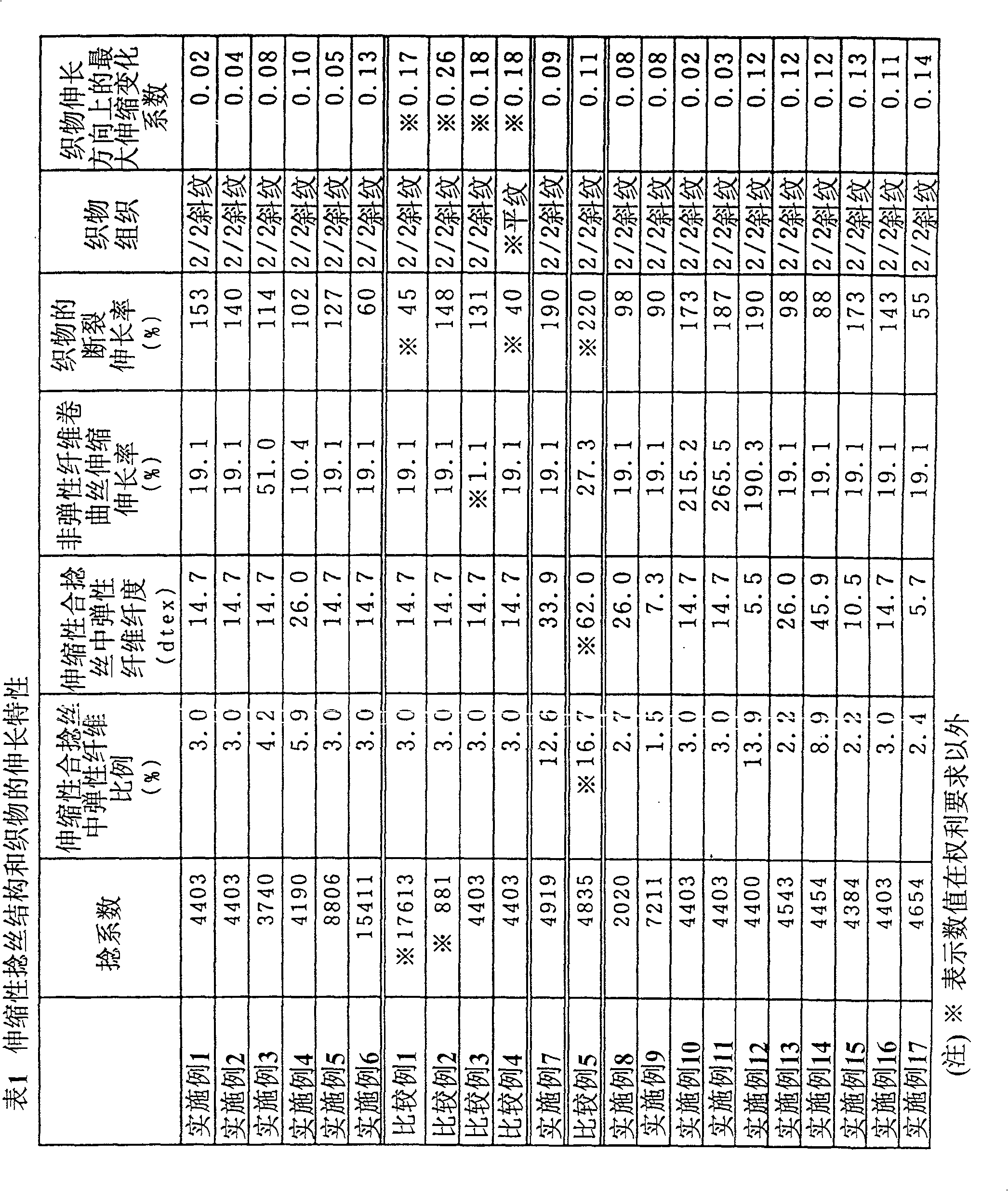

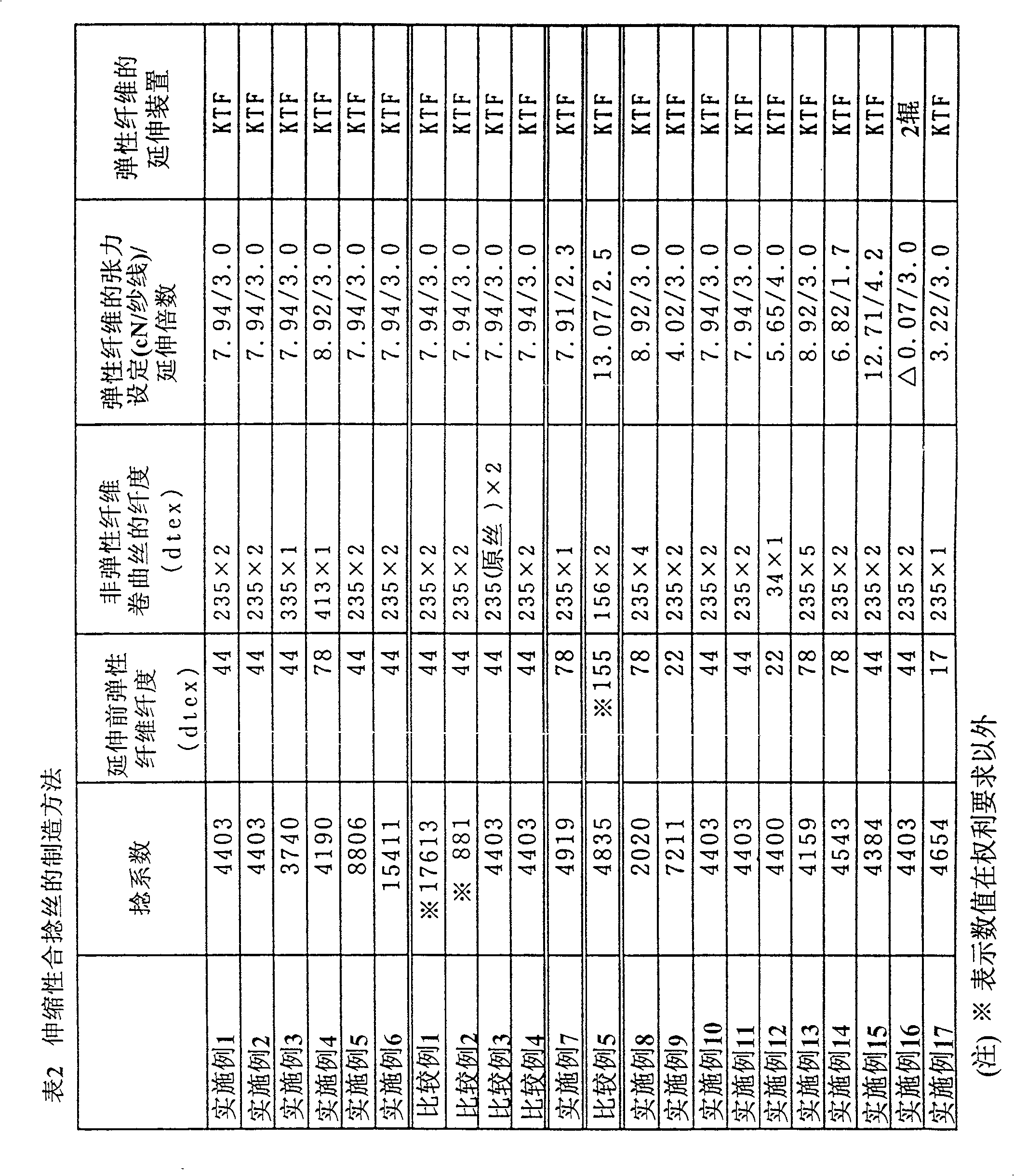

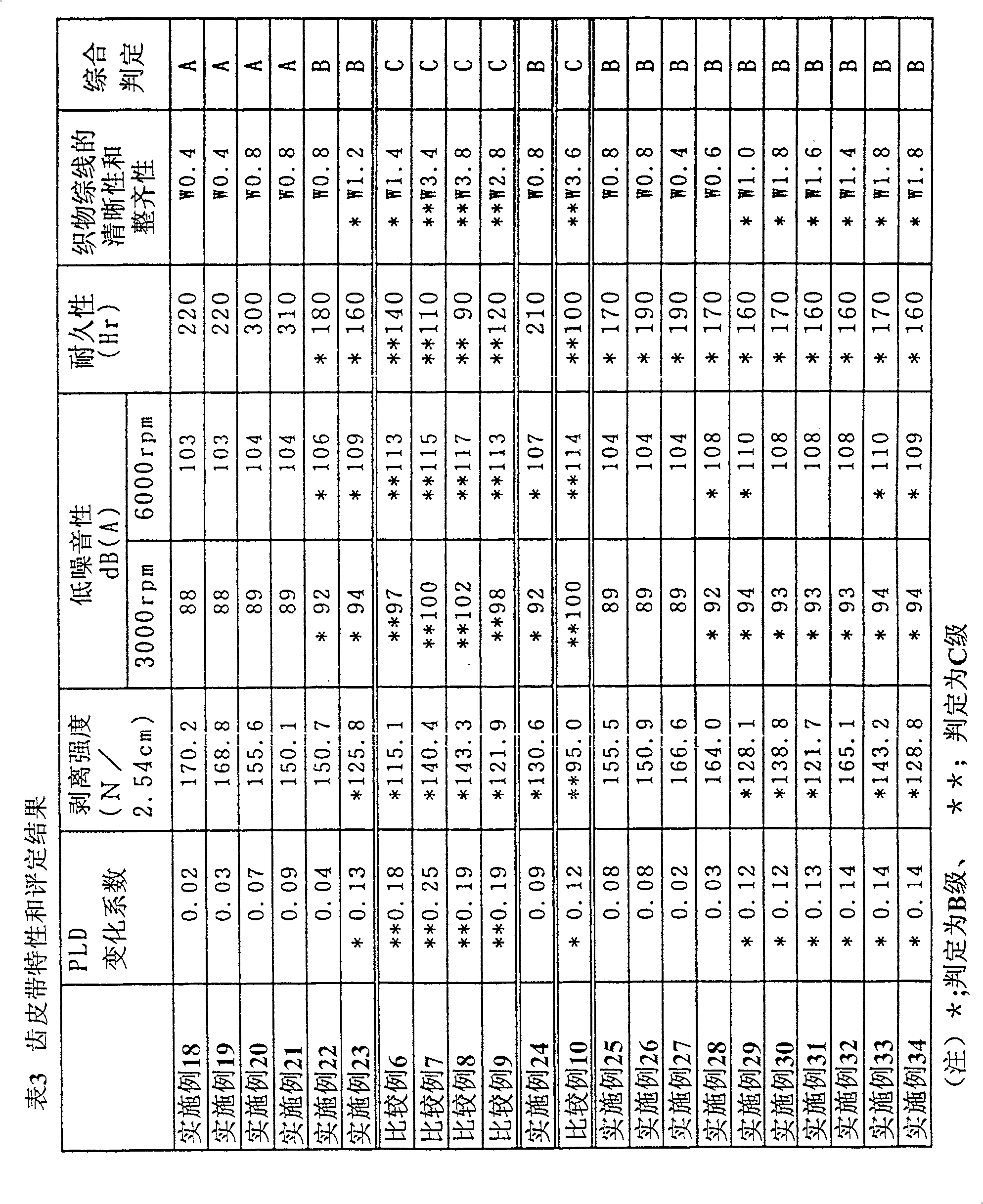

[0104] Urethane-based elastic fibers (manufactured by Asahi Kasei Co., Ltd.: trade name: Roika) 44 dtex as elastic fibers and polyamide multifilaments (manufactured by Asahi Kasei Co., Ltd.: trade name Leona) 235 dtex / 35f as inelastic crimped yarns are used Friction type false twisting machine (Barmag company manufacture: Model FK-6) carries out 2 strands (false twisting process twisting direction Z, telescopic elongation 19.1%) of high-speed false twisting process with false twisting speed 500m / min, with tension Loading machine (manufactured by BTSR company, product name KTF / 25HPS type) sets the tension of elastic fiber feeding to 7.94cN / yarn (equivalent extension ratio is 3.0), and sets the feeding tension of non-elastic fiber crimped silk to 0.03cN / Yarn, the elastic fiber and the non-elastic fiber crimped yarn are aligned on the twisting machine and then twisted. When twisting, use a twisting machine (manufactured by Ishikawa Seisakusho: Model DTH), with a spindle rotatio...

Embodiment 2

[0108] In Example 1, weft yarns were used instead of warp yarns (twisting direction Z), and a 2 / 2 twill fabric was woven with an air-jet loom (manufactured by Tsudakoma Industry Co., Ltd.: model ZA209) at a loom rotation speed of 400 rpm. Then, the gray cloth obtained is subjected to a series of treatments such as continuous expansion scouring-drying-finishing in the usual way. The warp density of the obtained fabric is 67 / 2.54cm, the weft density is 85 / 2.54cm, and the elongation at break in the warp direction is 140%. As shown in Table 1, the maximum expansion coefficient of the fabric is 0.04, which is very good. of.

Embodiment 3

[0110] In Example 1, polyurethane elastic fibers (manufactured by Asahi Kasei Co., Ltd.: trade name ロイカ) 44dtex as elastic fibers and polyketone fibers 335dtex / 250f as inelastic fiber crimped yarns were used for needle false twisting. Machine (manufactured by Ishikawa: Model IVF-338), carries out the thread sliver (false twist twist direction Z, telescopic elongation 51.0%) of false twist processing with the false twist speed of 50m / min, obtains twist number 200T / m (twisting direction S, twist coefficient 3740) stretchable twisted yarn. The fineness of the elastic fiber in this stretchable twisted yarn is 44 / 3.0=14.7dtex, and its proportion is 4.2wt%.

[0111] Then carry out the same weaving as in Example 1, and carry out a series of treatments of continuous expansion scouring-drying-finishing to the gray cloth obtained in a general method, and the obtained fabric warp density is 80 / 2.54cm, and the weft density is 79 strands / 2.54cm, the weft elongation at break is 110%, as s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com