1000 MW thermal power unit booster pump

A technology of thermal power units and pre-pumps, which is applied to pumps, pump components, mechanical equipment, etc., can solve the problems of unfavorable long-term stable operation of power plants, high maintenance costs, and impacts, so as to ensure long-term stable operation, reduce sealing area, and ensure The effect of the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

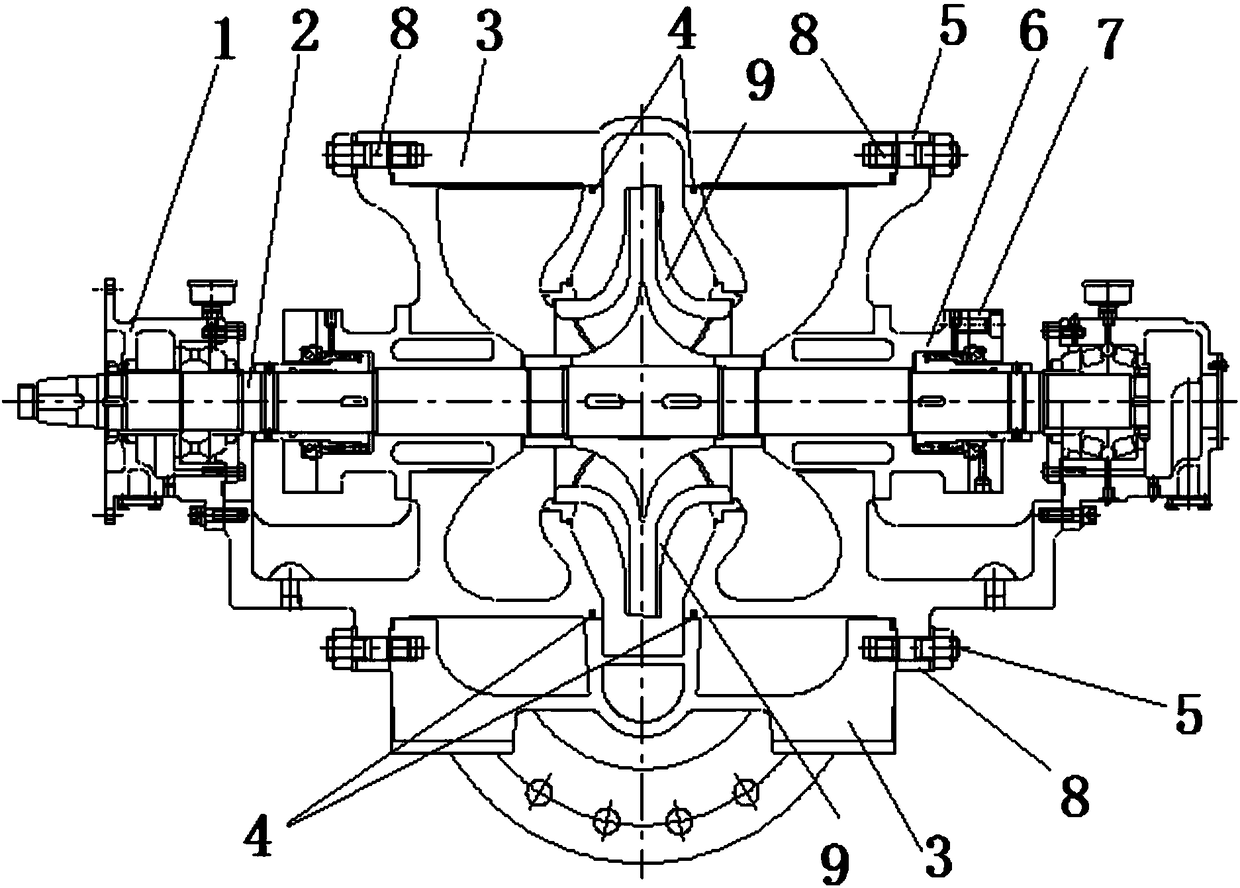

[0016] A 1000MW thermal power unit front pump, its structure is as follows figure 1 As shown, it includes a bearing chamber 1, a cooling chamber 6, a main shaft 2 and an impeller 9. The main shaft 2 runs through the bearing chamber 1 and is connected to the cooling chamber 6 through a mechanical seal 7. The impeller 9 is fixedly installed in the middle of the main shaft 2. The front pump also includes Two detachable end covers 5 and a U-shaped pump casing unit, when installed, the two end covers 5 are symmetrically installed on both sides of the bearing chamber 1, and the connecting line between the centers of the two end covers 5 is perpendicular to the main shaft 2, Both ends of the pump casing unit are fixedly connected with two end covers 5 respectively.

[0017] The bearing chamber 1 of the front pump is integrally formed, and there is no sealing problem. The end cover 5 and the pump casing unit are installed on both sides of the bearing chamber 1, that is, the radially s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap