Clutch disc and clutch

A technology for clutches and moving discs, which is applied in the field of clutches, and can solve problems such as the vibration damping spring 4 not exerting the anti-torsion and vibration damping function, resonance of the clutch driven disc, noise pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

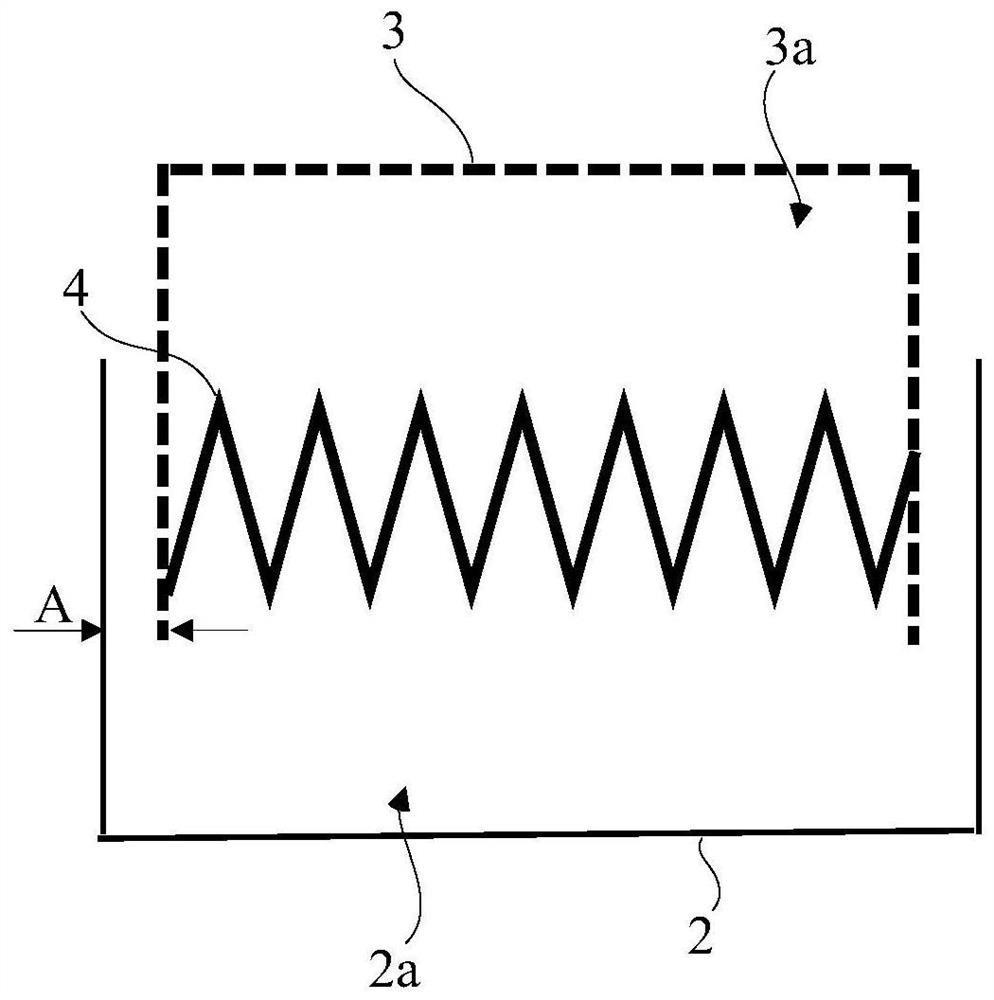

[0029] refer to figure 2 , In the prior art, the driven disc body 3 has a first hole 3a, the hub flange 2 has a second hole 2a, and the first hole 3a and the second hole 2a are axially opposite. Due to machining errors, there is a gap A ( figure 2 shown in ). The damping spring 4 is engaged with the first hole 3 a on the driven disk body 3 along its own elastic deformation direction, and is arranged with a gap between both side walls of the second hole 2 b on the hub flange 2 .

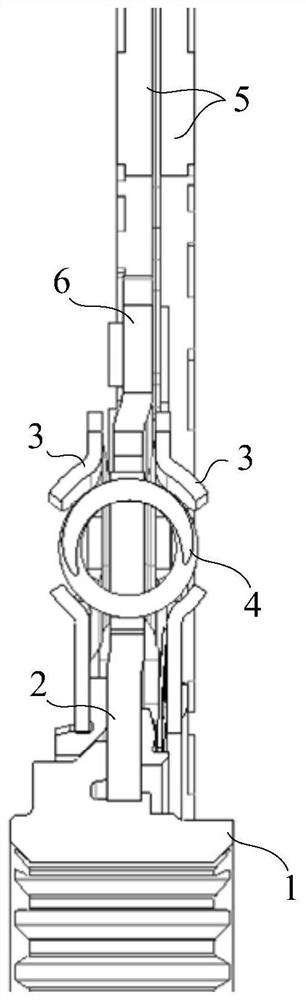

[0030] combine figure 1 As shown, under this structure, the friction plate 5 transmits the torque output by the engine to the driven disc body 3, and the driven disc body 3 will rotate relative to the hub flange 2, because the damping spring 4 and the hub fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com