Resonance resistance type crane double-beam conveying device

A beam conveying and crane technology, applied in the field of anti-resonance crane double beam conveying device, can solve the problems of left and right deviation of the main beam, inaccurate moving position, low efficiency, damage to the main beam, etc., so as to improve the conveying efficiency and eliminate the resonance phenomenon. , the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

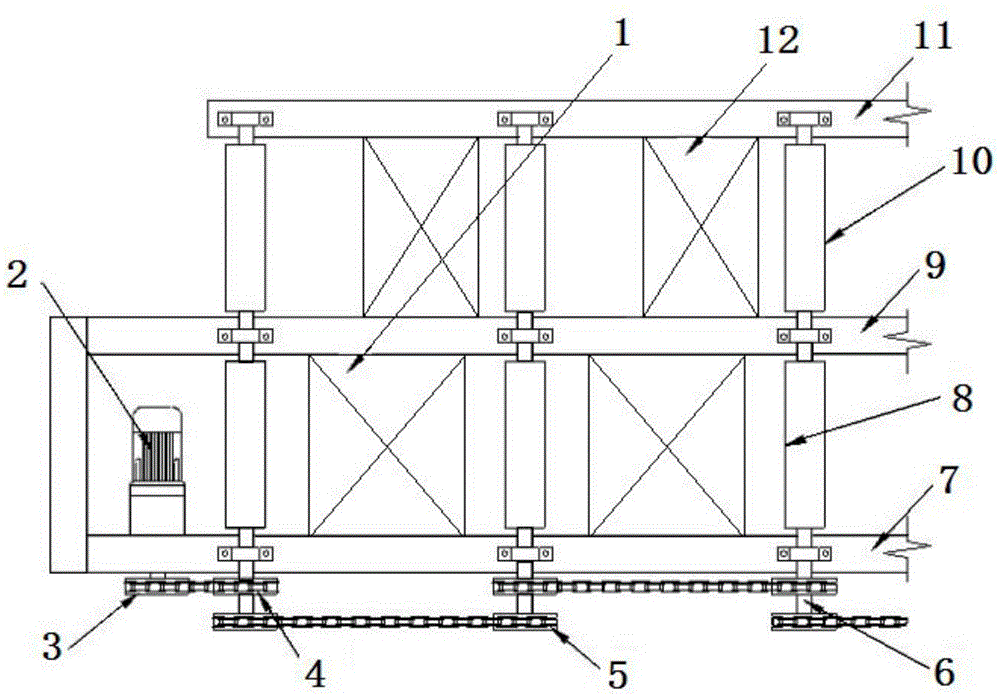

[0013] see figure 1 , an anti-resonance type crane double-girder conveying device, which includes a first beam 7, one side of one end of the first beam 7 is provided with a reduction motor 2, the reduction motor 2 is connected with a first gear 3 through a shaft, and the first beam 7 The upper side of the second beam 9 is provided with the second beam 9, and the upper side of the second beam 9 is provided with the third beam 11, and the first rollers are evenly arranged between the first beam 7 and the second beam 9 from left to right. Between the shaft 8, the second beam 9 and the third beam 11, there are second rollers 10 evenly arranged from left to right, and the first roller 8 and the second roller 10 pass through the rotating shaft 8; the rotating shaft One end of 8 is provided with the second gear 5, the upper side of the second gear 5 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com