Cooling anti-explosion watertight valve for gas pipeline

A gas pipeline, watertight technology, applied in valve details, valve device, valve shell structure, etc., to achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

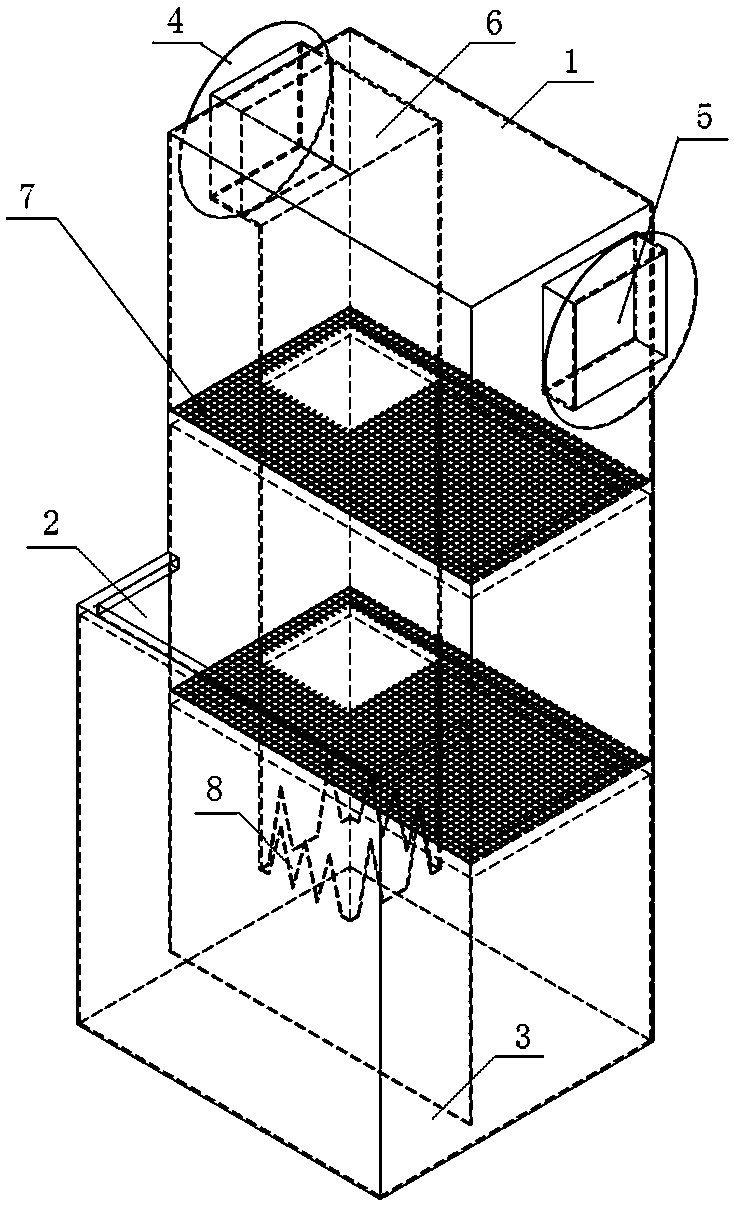

[0019] A cooling and explosion-proof watertight valve for gas pipelines, comprising a valve body, on which a cooling flame-retardant chamber 1 and a pressure relief chamber 2 are arranged, the cooling flame-retardant chamber 1 and the pressure relief chamber 2 are arranged side by side, and the two chambers There is a bottom gap 3 on the bottom of the chamber between the partitions, and the two chambers are filled with liquid and communicated through the bottom gap 3; a valve inlet 4 and a valve outlet 5 are set on the cooling flame-retardant chamber 1, and the valve inlet 4. An inner air intake pipe 6 is arranged in the cooling flame retardant chamber 1, the air outlet of the inner air inlet pipe 6 is located in the liquid-filled chamber, and the top of the pressure relief chamber 2 is open.

Embodiment 2

[0021] As a preference of Embodiment 1, the height of the pressure relief chamber 2 is lower than that of the temperature-reducing flame-retardant chamber 1 . When the pressure relief chamber is equal to or higher than the cooling flame retardant chamber, it will cause the filling liquid to enter the intake port during the pressure relief process, which is generally not acceptable.

[0022] As a further optimization of the structure, the height of the pressure relief chamber 2 is 1 / 2-1 / 3 of the height of the temperature-reducing flame-retardant chamber 1 .

[0023] As a preference, the inventors found that when the height of the pressure relief chamber 2 is 1 / 2 of the height of the temperature-reducing flame-retardant chamber 1 and the width is 1 / 2 of the width of the temperature-reducing flame-retardant chamber 1, the pressure relief speed is fast , and it will not cause the filling liquid to enter the intake end during the pressure relief process, and when the filling liquid...

Embodiment 3

[0025] As a specific structure of Embodiment 1, a valve air inlet 4 is provided on one side of the upper part of the temperature-reducing flame-retardant chamber 1 , and a valve air outlet 5 is provided on the upper part of the other side corresponding to the valve air inlet 4 .

[0026] The height of the bottom gap 3 is 1 / 35-1 / 45 of the height of the cooling flame-retardant chamber 1 .

[0027] The height of the air outlet of the inner air intake pipe 6 from the bottom of the chamber is 3 to 4 times the height of the bottom gap 3 .

[0028] The pipe body of the inner air intake pipe 6 runs through two steel mesh layers 7 , and several teeth 8 are arranged on the air outlet pipe body of the inner air intake pipe 6 .

[0029] In order to further ensure that the valve body will not leak the intake air during intake air, and will not cause the intake air to stay as air bubbles in the liquid filling, and can realize rapid pressure release when the pressure is released, the above s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com