Waterproof processing technology of fountain buried lamp

A processing technology and buried lamp technology, which can be used in gas-proof/waterproof devices, decorative art, lighting and heating equipment, etc. It can solve the problems of loose wire fixing and affecting the sealing performance, so as to ensure the sealing effect and increase the sealing performance , the effect of adding twists and complexity

Active Publication Date: 2020-04-03

重庆九日电子科技有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention intends to provide a waterproof processing technology for fountain buried lights, which can solve the problems that gaps are easily generated between the sealant and the wires and between the wires and the insulation skin, so that the wires are not fixed tightly and the sealing performance is affected

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0034] The following is further described in detail through specific implementation methods:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

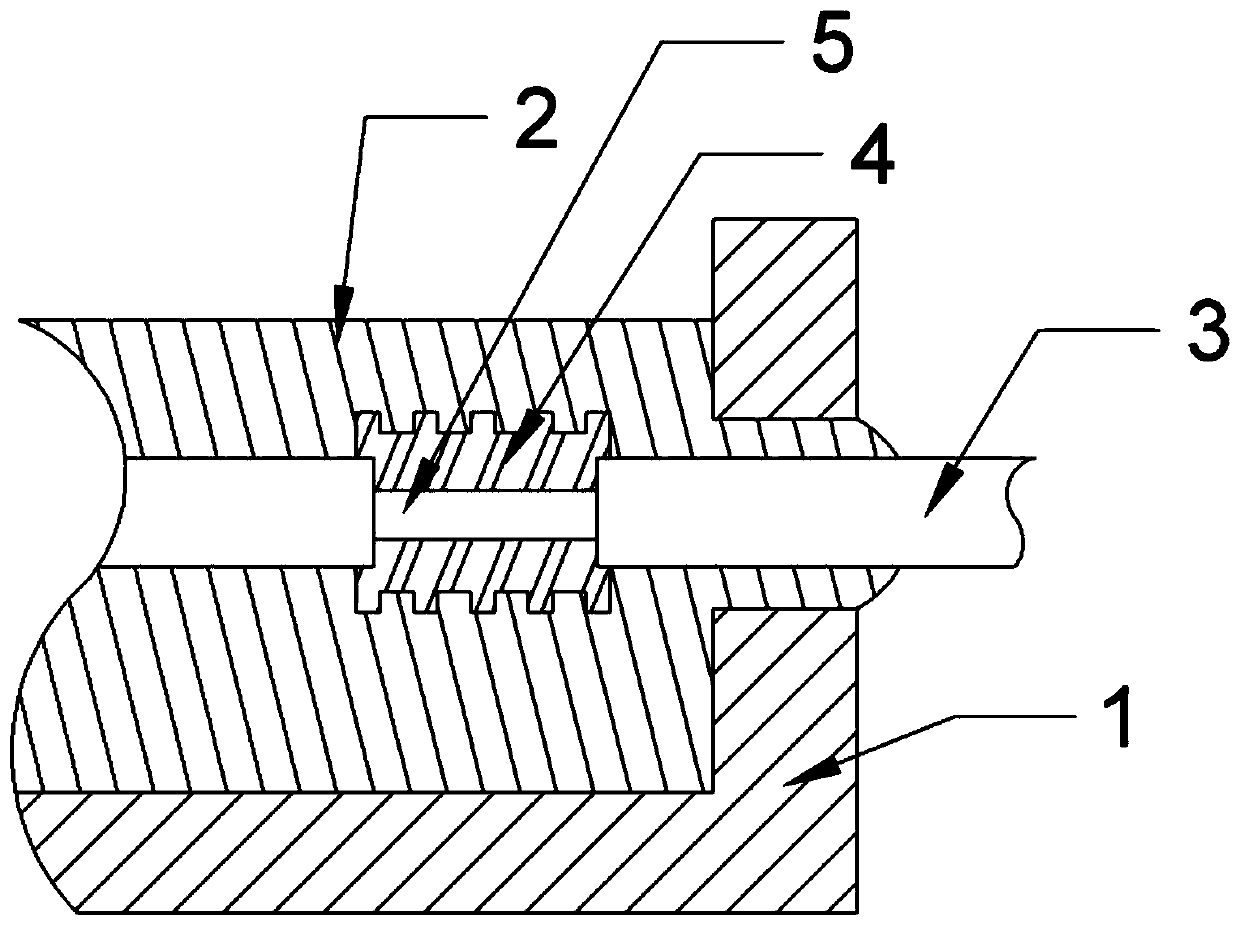

The invention relates to the technical field of big data processing systems, in particular to a waterproof processing technology of a fountain buried lamp. The waterproof processing technology comprises the following steps of 1) wire processing; 2) wire tinning; 3) installation and fixing; and 4) glue filling and sealing. In the step 1), a notch is stripped on an insulating layer of a wire; in thestep 2), tinning is carried out on the notch of the wire through tin soldering; in the step 3), the wire is inserted into the lamp body of the buried lamp and is fixed; and in the step 4), glue filling is carried out on the lamp body, and the wire is sealed in glue water. The wire tinning specifically comprises the following steps that 1) the upper paint part of the wire is clamped to a mold, tinpaste is injected into the mold, and a plurality of convex rings are arranged on the side wall of the mold cavity; 2) the mold is heated to enable the solder paste to be melted; and 3) the mold is cooled and opened. According to the waterproof processing technology of the fountain buried lamp, a gap can be easily generated between the sealing glue and the wire and between the wire and the insulating skin, and the problems that the wire is fixed and the sealing performance is influenced are solved.

Description

technical field [0001] The invention relates to the technical field of lamp processing technology, in particular to a waterproof processing technology for fountain buried lamps. Background technique [0002] LED underground lights are lamps buried on the surface of the ground. They are widely used in outdoor lighting such as squares and outdoor parks. In addition to setting off the environment and adding color to life, they can also be used as guiding lights on roads in parks. Underground lights can also be designed Chengcheng fire emergency sign underground lights are used in shopping malls, parking lots and other public places to provide evacuation instructions for people in danger. Because LED underground lights have many advantages such as low power consumption and easy color control, LED underground lights are widely used in light fountains. [0003] The underground lamp used for fountains includes a lamp body, which includes a lamp head and a connecting part. There is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F21V31/04F21V23/00F21W121/02F21Y115/10

CPCF21V23/002F21V31/04F21W2121/02F21Y2115/10

Inventor 柏世洪

Owner 重庆九日电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com