A precise powder supply device for accelerated dust accumulation test of air conditioner heat exchanger

A powder supply device and heat exchanger technology, applied in heat exchange simulation, heat exchange equipment, lighting and heating equipment, etc., to achieve the effect of strong operability, simple and practical structure, simple and reliable standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

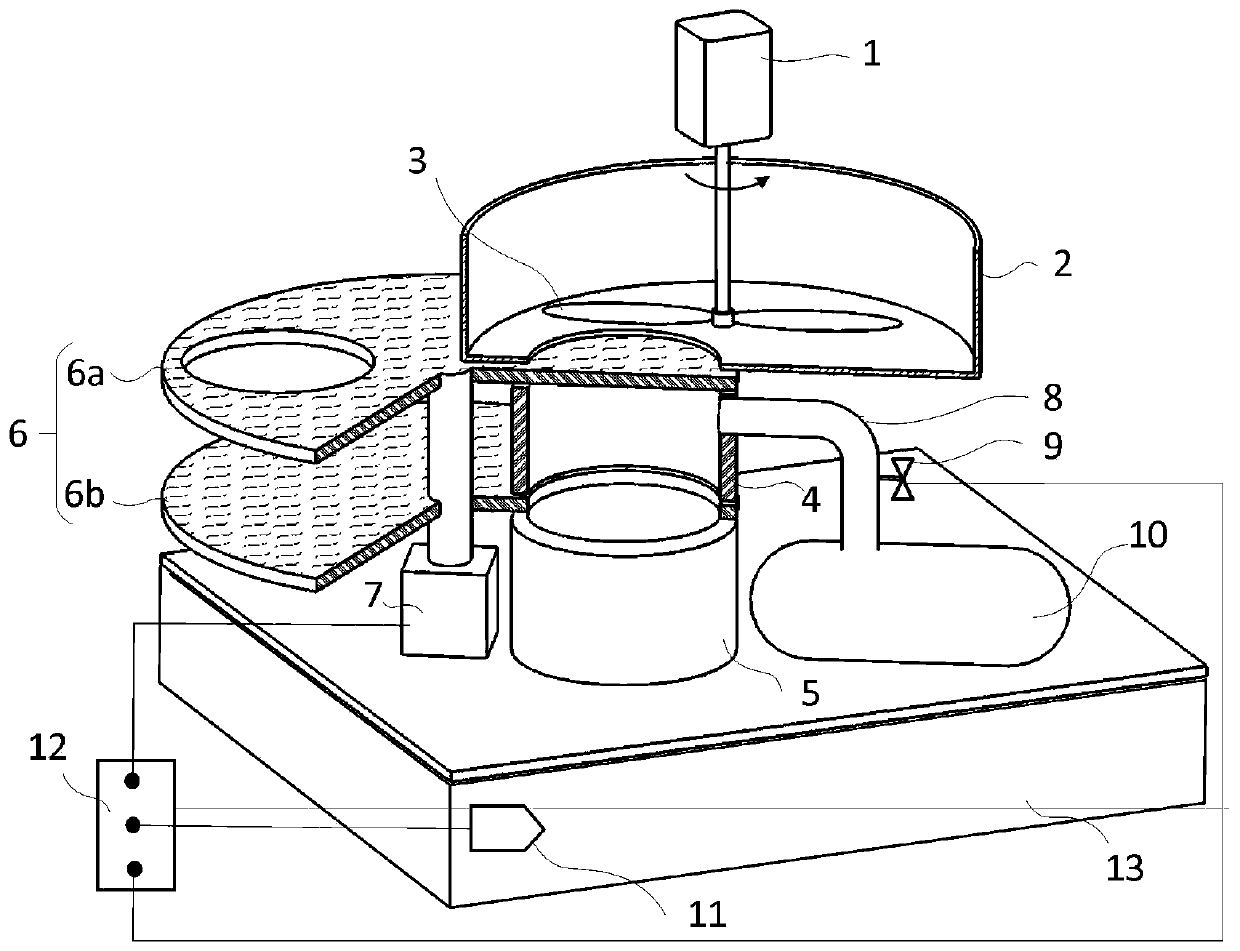

[0031] figure 1 Shown is a schematic diagram of a precise powder supply device for an air conditioner heat exchanger accelerated dust accumulation test according to a preferred embodiment of the present invention, including a rotating motor 1, a dust container 2, a mixing impeller blade 3, a miniature cylinder 4, a dust Conveying pipe 5, sheet switch valve 6, stepper motor 7, powder blowing module, programmable controller 12 and dust accumulation chamber 13; the rotating shaft of rotating motor 1 is connected with mixing impeller blade 3; the dust holding container 2 has no cover on the upper end 1. A metal cylinder with a hole in the bottom, the mixing impeller 3 and the rotating motor 1 are installed in the dust container 2; the sheet switch valve 6 is close to the bottom of the dust container 2, including the upper disc valve 6a and the lower disc valve 6b; the miniature cylinder 4 is a cylinder without a cover at both ends, and the upper end and the lower end of the miniat...

Embodiment 2

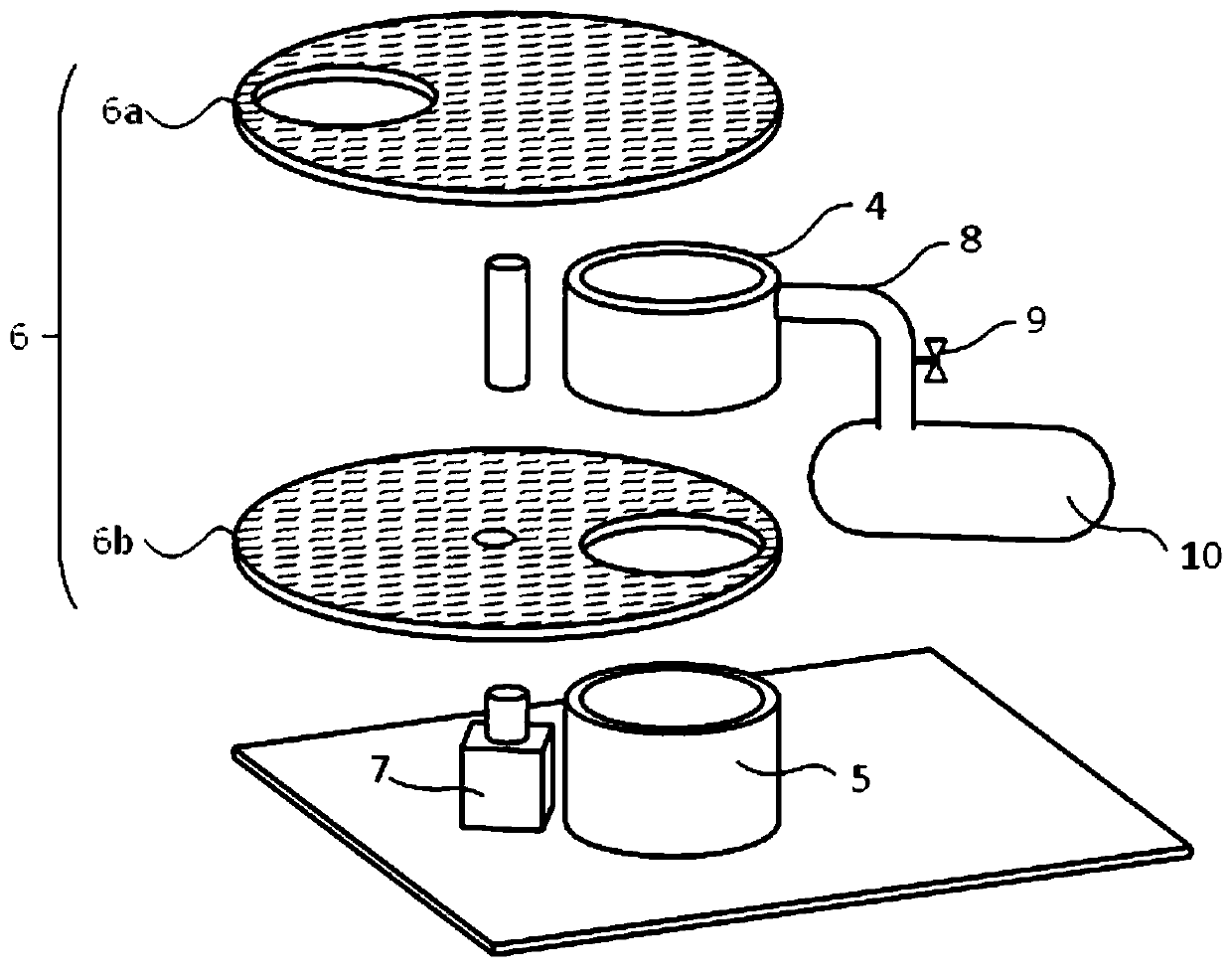

[0036] figure 2 Shown is a partially disassembled diagram of an accurate powder supply device for testing accelerated dust accumulation of an air conditioner heat exchanger according to another preferred embodiment of the present invention. In this embodiment, the sheet-shaped switch valve 6 is composed of two upper and lower disc valves 6 a and lower disc valves 6 b with the same outer diameter.

[0037] In order to improve the dust flow efficiency of the dust holding container 2, the miniature cylindrical straight barrel 4 and the sheet switch valve 6, preferably, the miniature cylindrical straight barrel 4 is a cylindrical straight barrel without a cover at both ends, and the position of the circular opening at the bottom of the dust holding container 2 is in line with the The miniature cylindrical cylinder 4 is coaxial and has the same diameter; the upper disc valve 6a and the lower disc valve 6b each have a circular hole, and the circular hole position of the lower disc ...

Embodiment 3

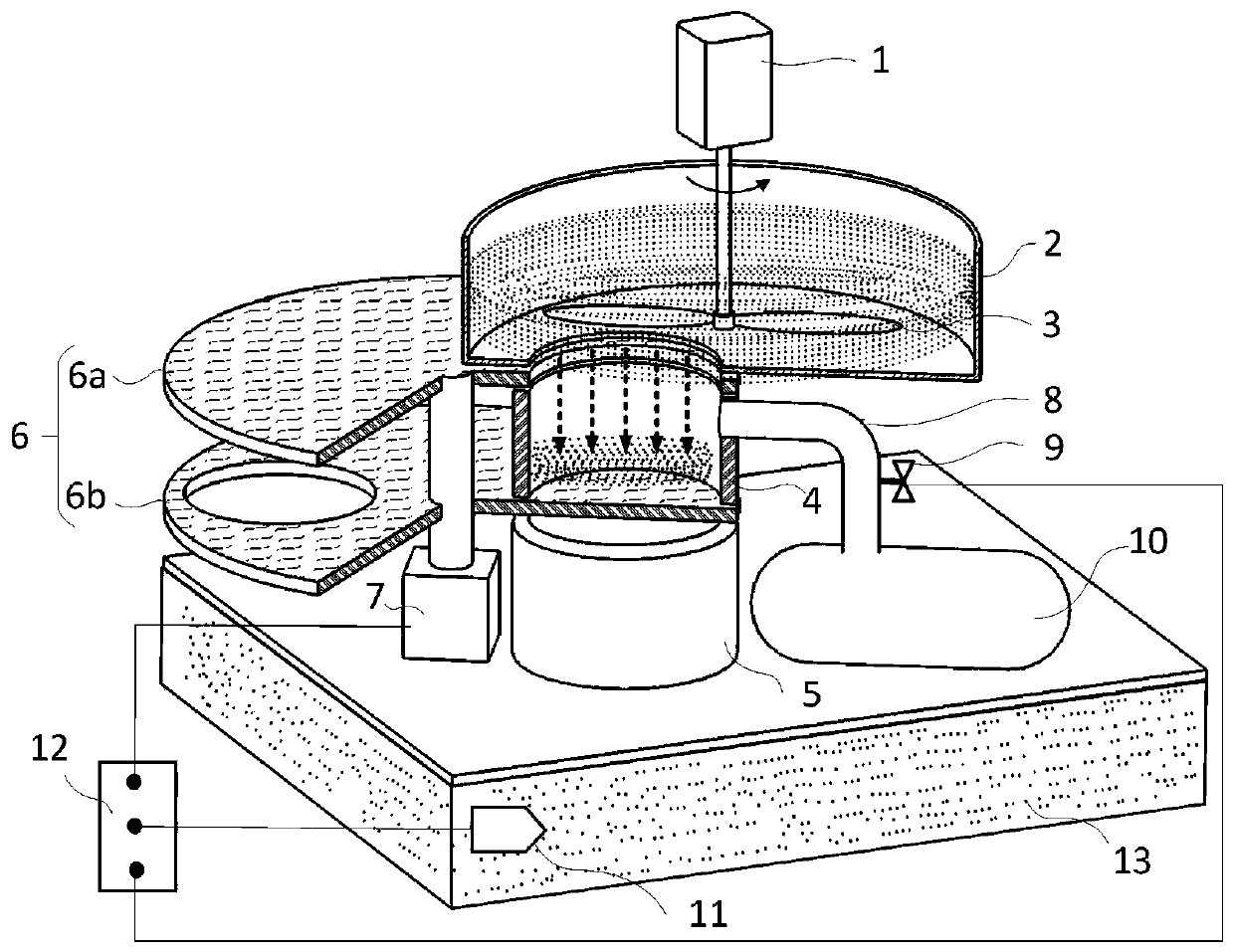

[0042] image 3 and Figure 4 They are respectively the schematic diagram of the dust adding process and the dust unloading process of another preferred embodiment of the present invention. In order to specifically illustrate the parameter design process of the equipment parameters of the corresponding device of the present invention based on specific working conditions, this embodiment provides a typical working condition and matching parameters:

[0043] In this embodiment, the volume of the dust chamber 13 is designed to be 10 cubic meters, and the dust concentration is set to 120 mg / m 3 . From the perspective of engineering practice, the lower limit of the dust concentration range is set to 100mg / m 3 , the upper limit is 140mg / m 3 . Through formula 10(m 3 )×(140-100)(mg / m 3 )=0.4(g), it can be seen that the maximum amount of dust that can be added at a time is 0.4g.

[0044] Therefore, the dimensions of the miniature cylinder 4 are designed to have an inner diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com