Silicon oxide and calcium oxide composite material and synthesis method thereof

A technology for composite materials and synthesis methods, applied in the field of silicon oxide-containing composite materials and their synthesis, can solve the problems of complex preparation methods and high costs, and achieve the effect of simple and easy synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: Preparation of different pH buffers

[0046] Configuration of PH4.5 buffer solution: Take 18g of sodium acetate and 9.8mL of glacial acetic acid, dilute with distilled water to a total volume of 1000mL.

[0047] The configuration of PH4.8 buffer solution: mix 19.96g sodium dihydrogen phosphate and 99.8mL distilled water to form A solution; mix 10.14g citric acid and 101.4mL distilled water to form B solution; mix AB to obtain buffer solution.

[0048] The configuration of PH5 buffer solution: mix 20.6g sodium dihydrogen phosphate and 103mL distilled water to form A solution; mix 9.7g citric acid and 97mL distilled water to form B solution; mix AB to obtain buffer solution.

[0049] The configuration of PH5.2 buffer solution: mix 21.44g sodium dihydrogen phosphate and 107.2mL distilled water to form A solution; mix 9.28g citric acid and 92.8mL distilled water to form B solution; mix AB to obtain buffer solution.

[0050] The configuration of PH5.6 buffer s...

Embodiment 2

[0052] Dissolve 3.8g of calcium nitrate and 1.8g of sodium hydroxide in 100mL of distilled water, stir for 1 hour and put it in a reaction kettle for 8 hours at 105°C; then wash the solid product with distilled water 4 times until neutral, and dry at 120°C for 12 hours to obtain calcium oxide;

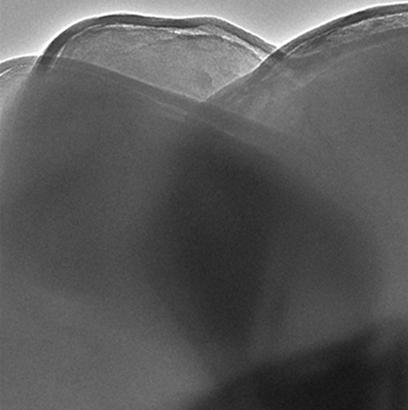

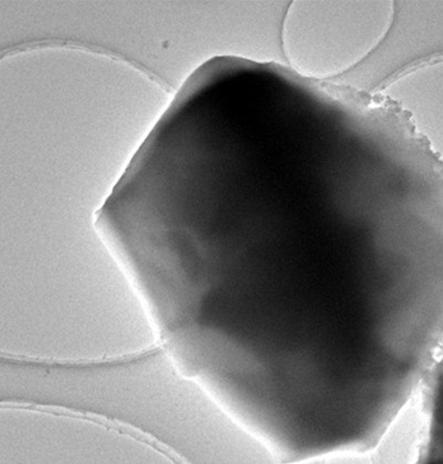

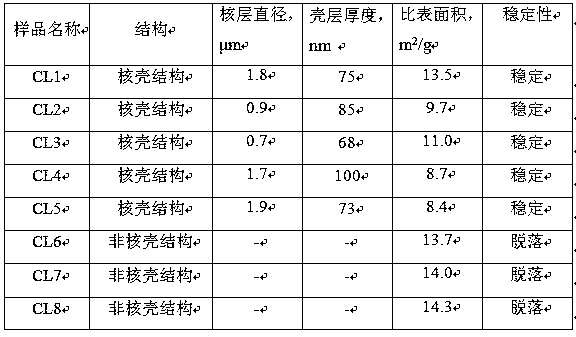

[0053] Then take 2.15g of the above-mentioned calcium oxide and place it in 38 mL of ethanol, stir for 0.5 h, then ultrasonicate for 3 h, the frequency of ultrasonic wave is 1 MHz, and the power is 50 W / L according to the volume of the solution; mL pH4.8 buffer solution, then add 1mL tetraethyl orthosilicate dropwise under the stirring condition of 120 rpm; after the dropwise addition, stir at the speed of 20 rpm for 5h, then place it in a water bath at 30°C 12h; wash the obtained product with distilled water 4 times until neutral, dry at 120°C for 12h, and treat at 260°C for 3h to obtain SiO 2 - Calcium oxide composite material, obtained sample number CL1. From figure 1 It can be se...

Embodiment 3

[0055] Dissolve 4g of calcium nitrate and 0.8g of sodium hydroxide in 40mL of distilled water, stir for 1 hour and put it in a reaction kettle for 5 hours at 120°C; then wash the solid product with distilled water 4 times until neutral, and dry at 120°C for 12 hours to obtain calcium oxide;

[0056] Then take 2 g of the above-mentioned calcium oxide and place it in 20 mL of ethanol, stir for 0.2 h, then ultrasonicate for 2 h, the frequency of the ultrasonic wave is 15KHz, and the power is 100W / L based on the solution volume; pH5.0 buffer solution, then add 0.36 mL tetraethyl orthosilicate dropwise under the stirring condition of 280 rpm; after the dropwise addition, stir at the speed of 50 rpm for 2 h, and then place it in a water bath at 25 °C Stand still for 6h; wash the obtained product with distilled water 4 times until neutral, dry at 120°C for 12h, and treat at 280°C for 2h to obtain SiO 2 - Calcium oxide composite material, obtained sample number CL2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com