Electronic component test system

A technology of electronic components and test systems, which is applied in the parts of electrical measuring instruments, measuring electricity, measuring devices, etc., can solve the problems of improving the test capacity and other problems, and achieve the effect of reducing the test empty window time and improving the test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

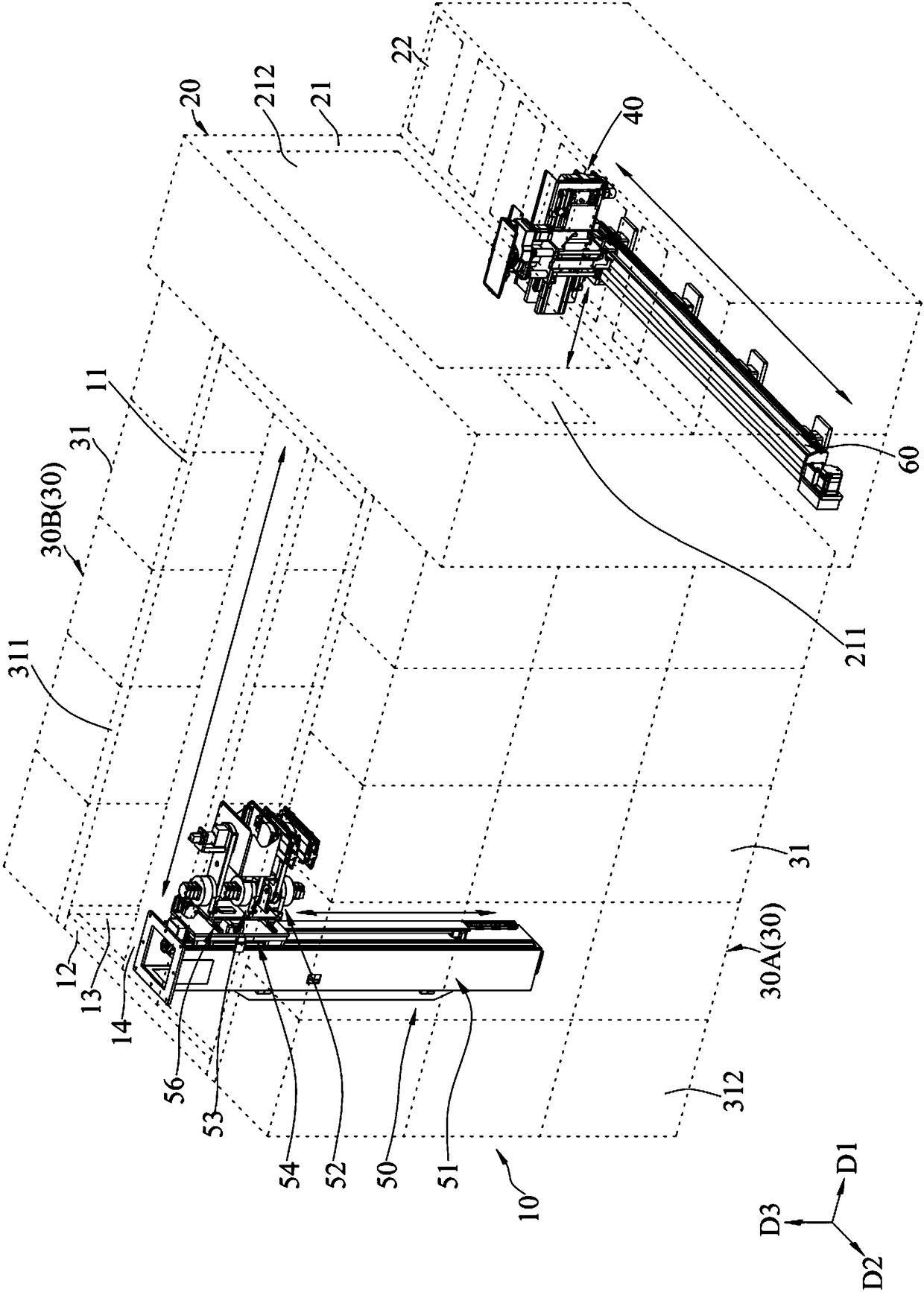

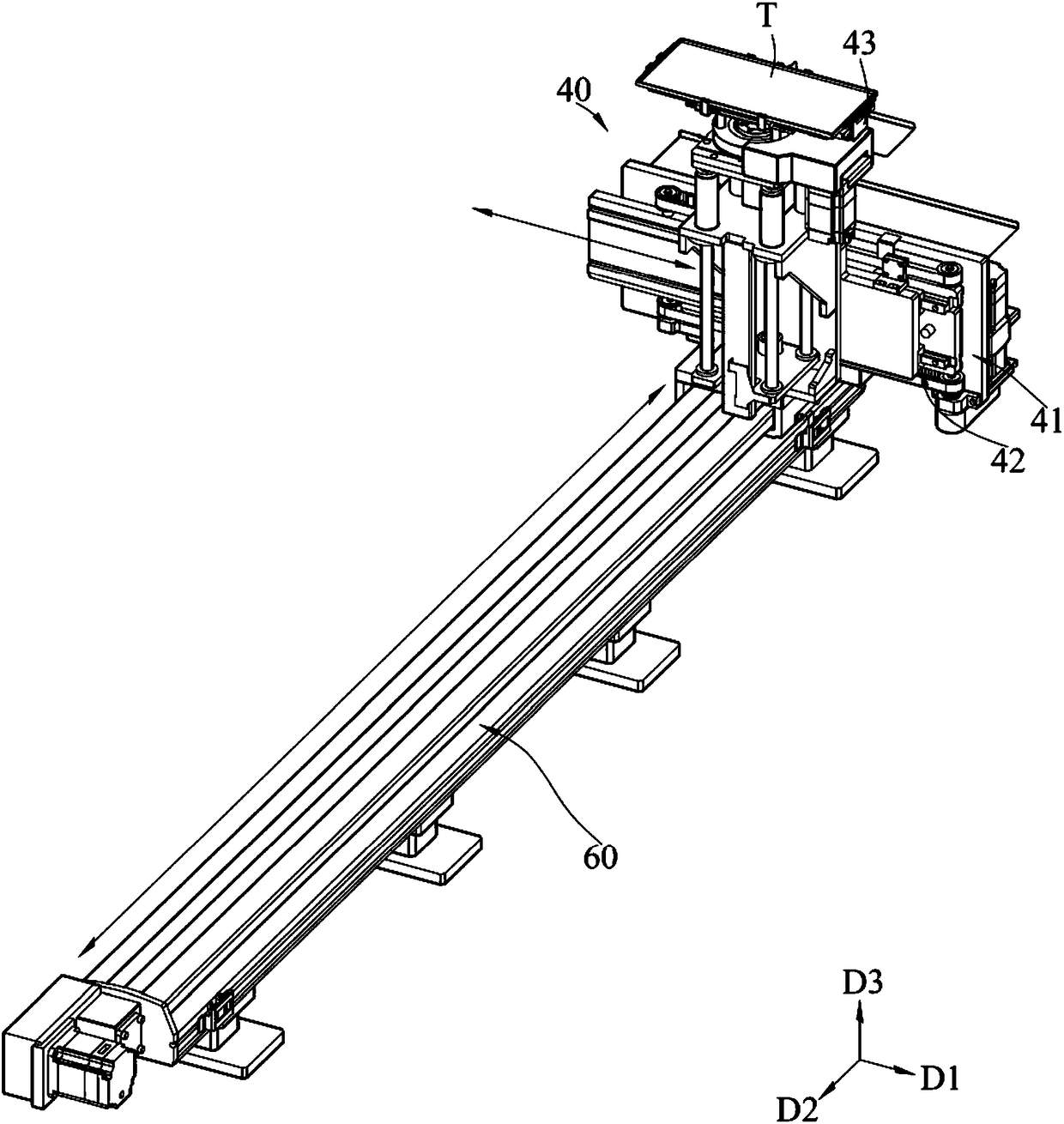

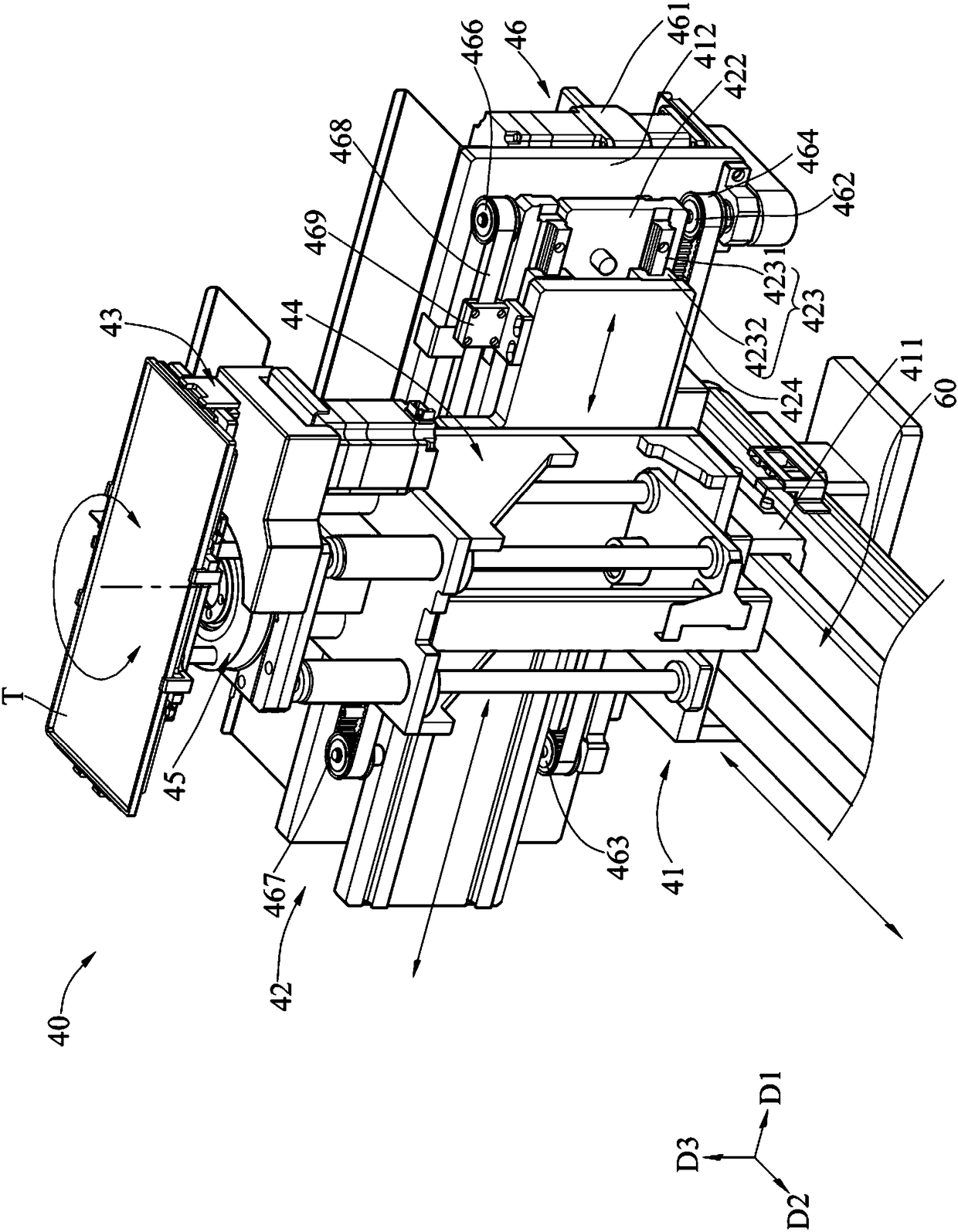

[0050] Please refer to figure 1 , figure 1 It is a main configuration diagram of an embodiment of the electronic component testing system of the present invention. In one embodiment, the electronic component testing system includes a rack 10 , a tray placement area 20 , a testing area 30 , a transfer device 40 in the front area, and a transfer device 50 in the test area. The tray placement area 20 and the test area 30 are adjacently arranged on the frame 10 , and the front area transfer device 40 and the test area transfer device 50 are respectively movably arranged on the frame 10 . The tray placement area 20 is used for placing trays T. As shown in FIG. The testing area 30 includes an electronic component testing device 31 . The transfer device 40 in the front area can move between the tray placement area 20 and the test area 30 , and is used to pick and place the tray T in the tray placement area 20 . The test area transfer device 50 can move within the range of the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com