Raw material purchasing system for food processing

A technology of food processing and raw materials, which is applied in the direction of instruments, commerce, sales/lease transactions, etc., to achieve the effect of solving error-prone and preventing collusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

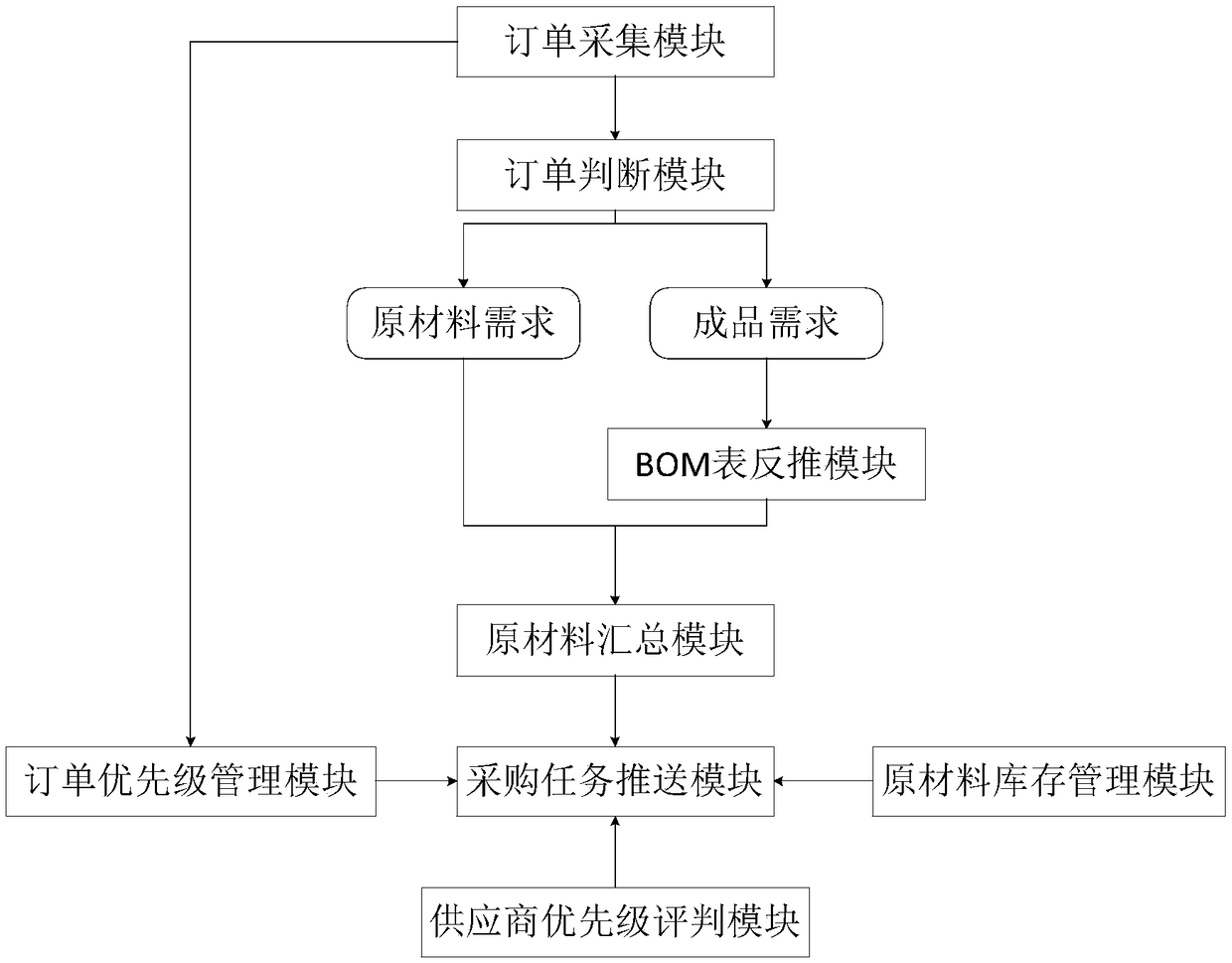

[0019] A raw material procurement system for food processing, which includes an order acquisition module, an order judgment module, a BOM reverse deduction module, a raw material summary module, a procurement task allocation module and a supplier priority evaluation module.

[0020] The order collection module is used to collect and manage all orders, and send all orders to the order judgment module.

[0021] The order judging module is used to classify all orders. According to the type of order, it is divided into two categories: raw material demand order and finished product demand order. The raw material demand order is sent to the raw material summary module, and the finished product demand order is sent to the BOM table Reverse module.

[0022] The BOM table inversion module includes a finished product raw material demand BOM table, which is used to compare the actual raw material demand of finished products in the finished product demand order, and sends the actual raw m...

Embodiment 2

[0027] The system in embodiment one also includes a raw material inventory management module, which is used to manage the inventory information of all raw materials (as the inventory of A raw material is a), and each raw material is provided with an inventory warning value (A The inventory warning value of raw materials is 100); the raw material inventory management module is also used to send the inventory difference (such as the inventory difference h=100-a of A raw material) of the raw materials whose inventory is lower than the early warning value to the procurement task assignment module, and the procurement task allocation module sends the inventory difference of the raw material to the corresponding buyer (that is, the raw material), and then the buyer completes the procurement task.

Embodiment 3

[0029] The system in embodiment one or two also includes an order priority management module, and the order priority management module is used to obtain all order completion times (such as completing the order task within three days, completing the order task within fifteen days, etc.) from the order collection module. ), and carry out priority division management to all orders according to the completion time of the order, all orders are divided into two categories: emergency orders and common orders; Y, finished product X needs raw materials l, k, and j, finished product Y needs raw materials l, k, m, and n, that is, the types of raw materials in the emergency order include l, k, j, m, and n) and send them to the procurement task allocation module,

[0030] The procurement task allocation module will relate to the total demand of raw materials (l, k, j, m and n) of urgent orders and the supplier with the highest priority of corresponding delivery speed (ie raw materials l, k,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com