Brush roller with bristles convenient to change for textile printing and dyeing machinery

A technology for textile printing and dyeing that is easy to replace. It is applied in the direction of brush bristle brackets, brushes, and applications. It can solve the problems of inconvenient replacement, high demand and consumption of brush rollers, and complicated procedures, and achieve simple and easy operation of the replacement steps and reduce Effect of replacement frequency and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

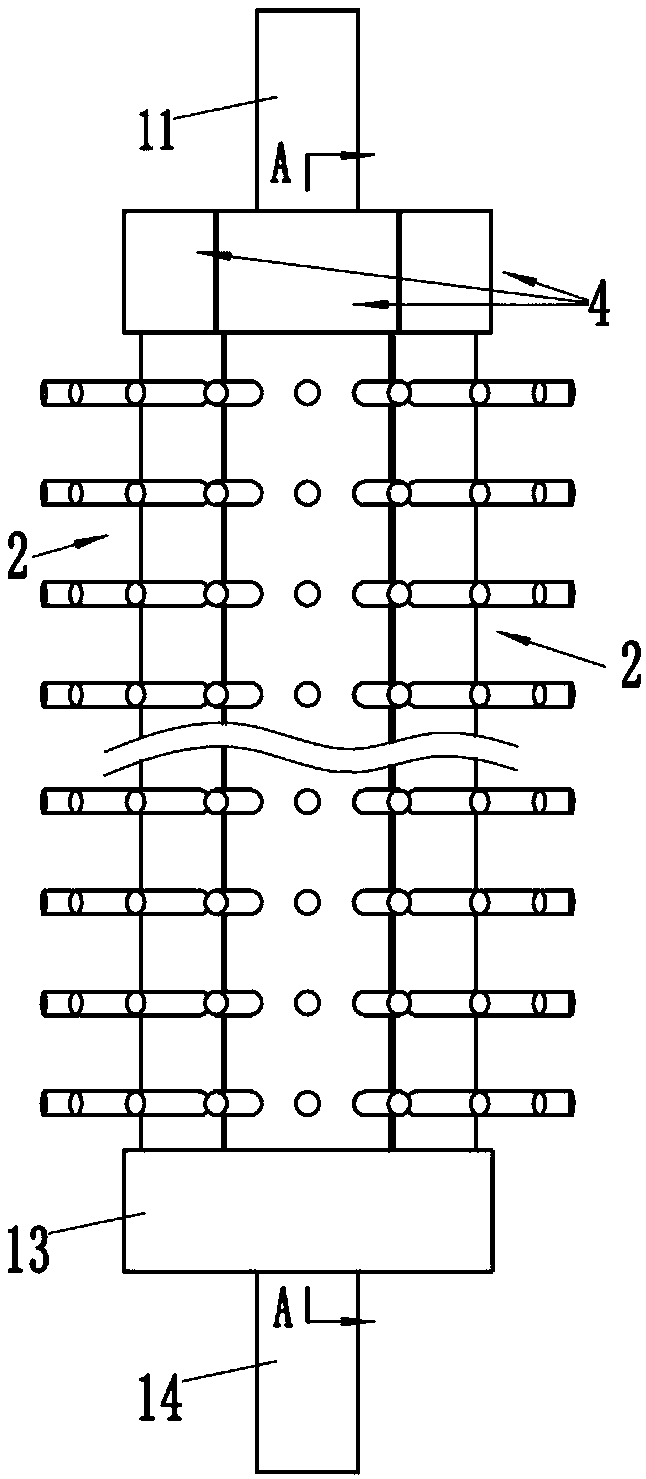

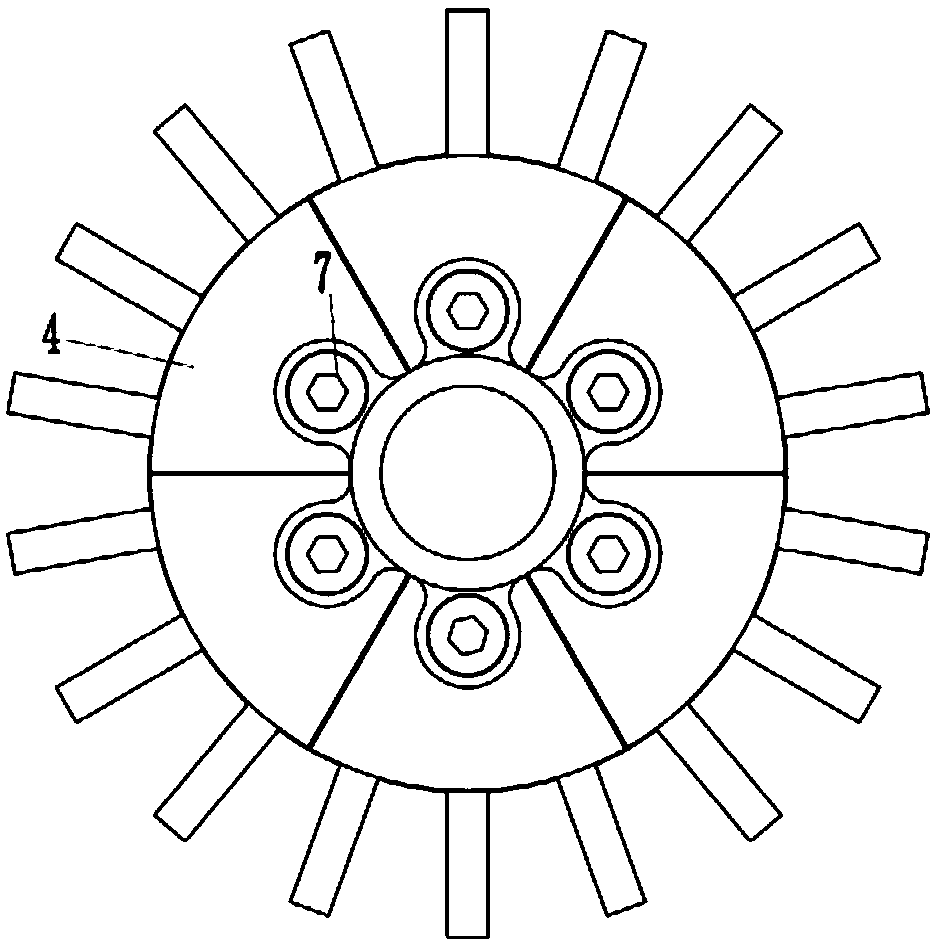

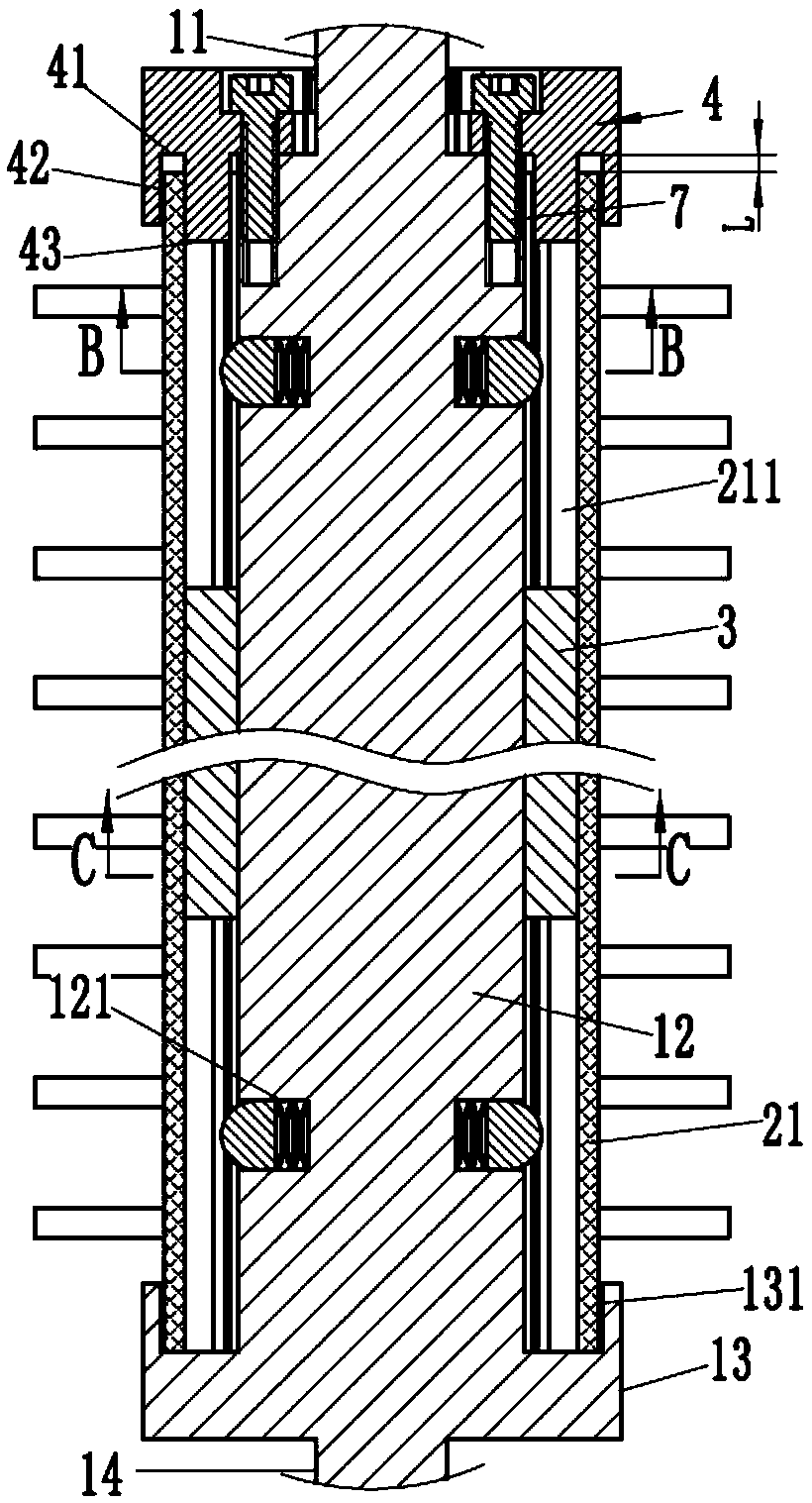

[0019] Examples, see e.g. Figure 1 to Figure 7 As shown, a brush roller for textile printing and dyeing machinery that facilitates the replacement of bristles includes an integrally formed upper mandrel 11, a regular prism 12, a lower baffle 13 and a lower mandrel 14, each of the regular prisms 12 A bristle module 2 is provided on the side, and the bristle module 2 includes an arc-shaped bristle attachment block 21 and a number of bristles 22 attached to the bristle attachment block 21; the middle part of each side of the regular prism 12 A T-shaped bar 3 is fixed, and a T-shaped long slot 211 is formed on the bristle attachment block 21, and each T-shaped bar 3 is inserted into the T-shaped long slot 211 of a corresponding bristle attachment block 21. The lower side of each bristle attachment block 21 is pressed against the lower baffle plate 13, and the upper end of each bristle attachment block 21 is respectively provided with a blocking portion 4, and each blocking portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com