Wall coating stirring and mixing device for civil engineering construction

A technology for mixing and mixing walls, which is applied to the field of wall coating mixing and mixing devices for civil construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

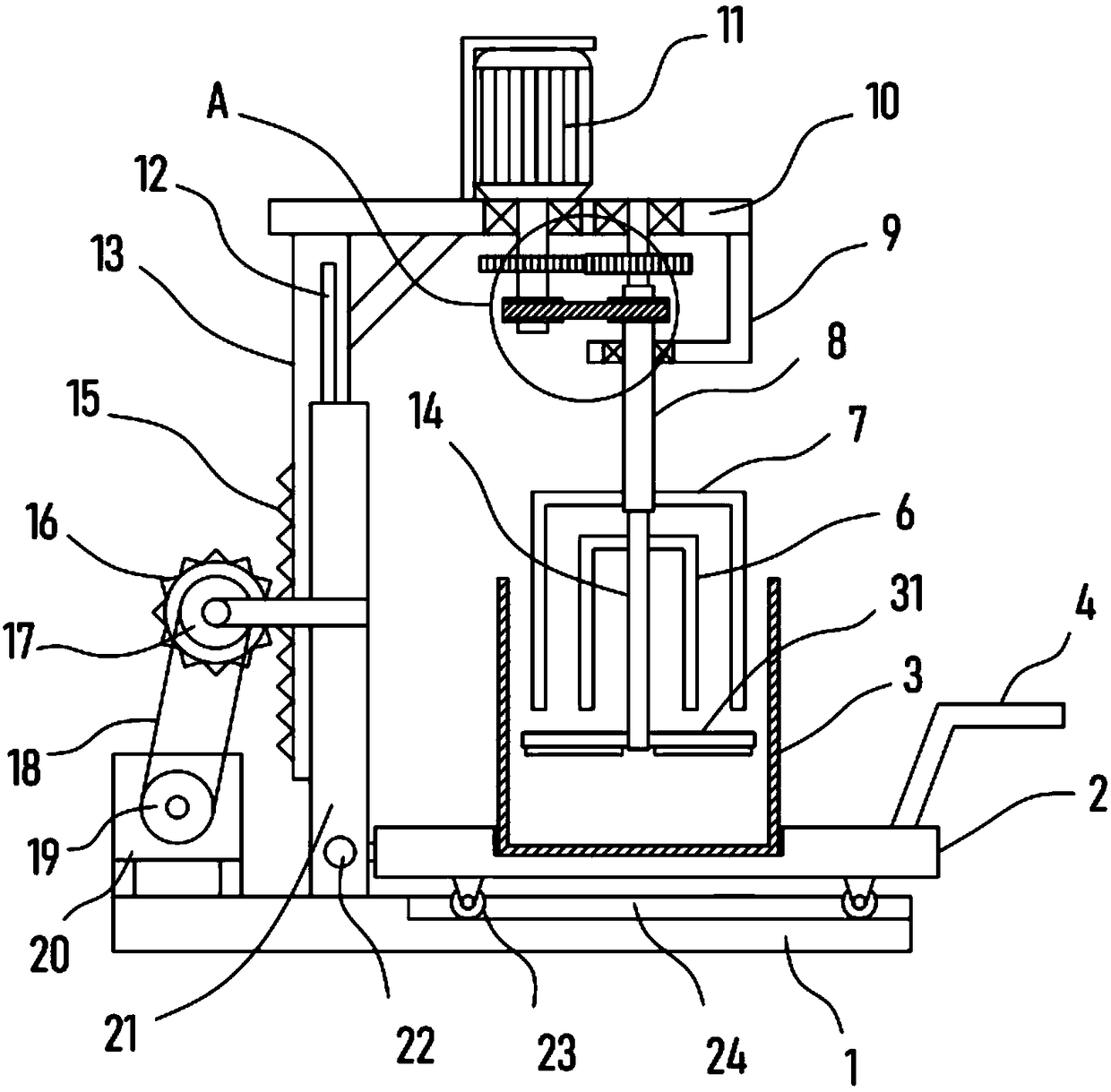

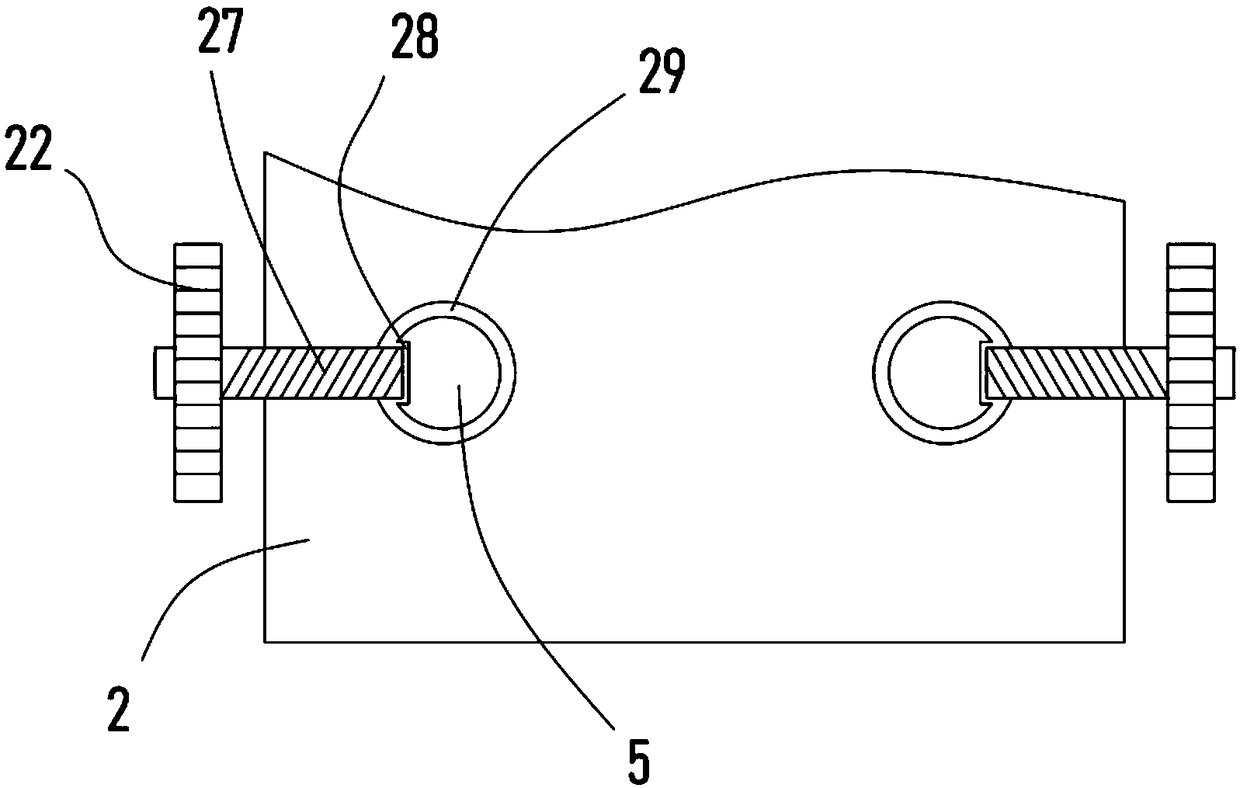

[0021] see Figure 1-3 , a wall paint stirring and mixing device for civil construction, including a base plate 1, a limit frame 21 is vertically fixed on the base plate 1, a lifting column 13 is vertically slid on the limit frame 21, and a lifting column 13 is fixed horizontally on the upper end of the lifting column 13. Top plate 10, a stirring motor 11 is fixed on the top plate 10, a sliding push plate 2 is provided on the bottom plate 1, a mixing bucket 3 is arranged on the sliding pushing plate 2, the sliding pushing plate 2 is used to support the mixing bucket 3, and the mixing bucket 3 is The open structure is used to store the architectural paint to be stirred and mixed.

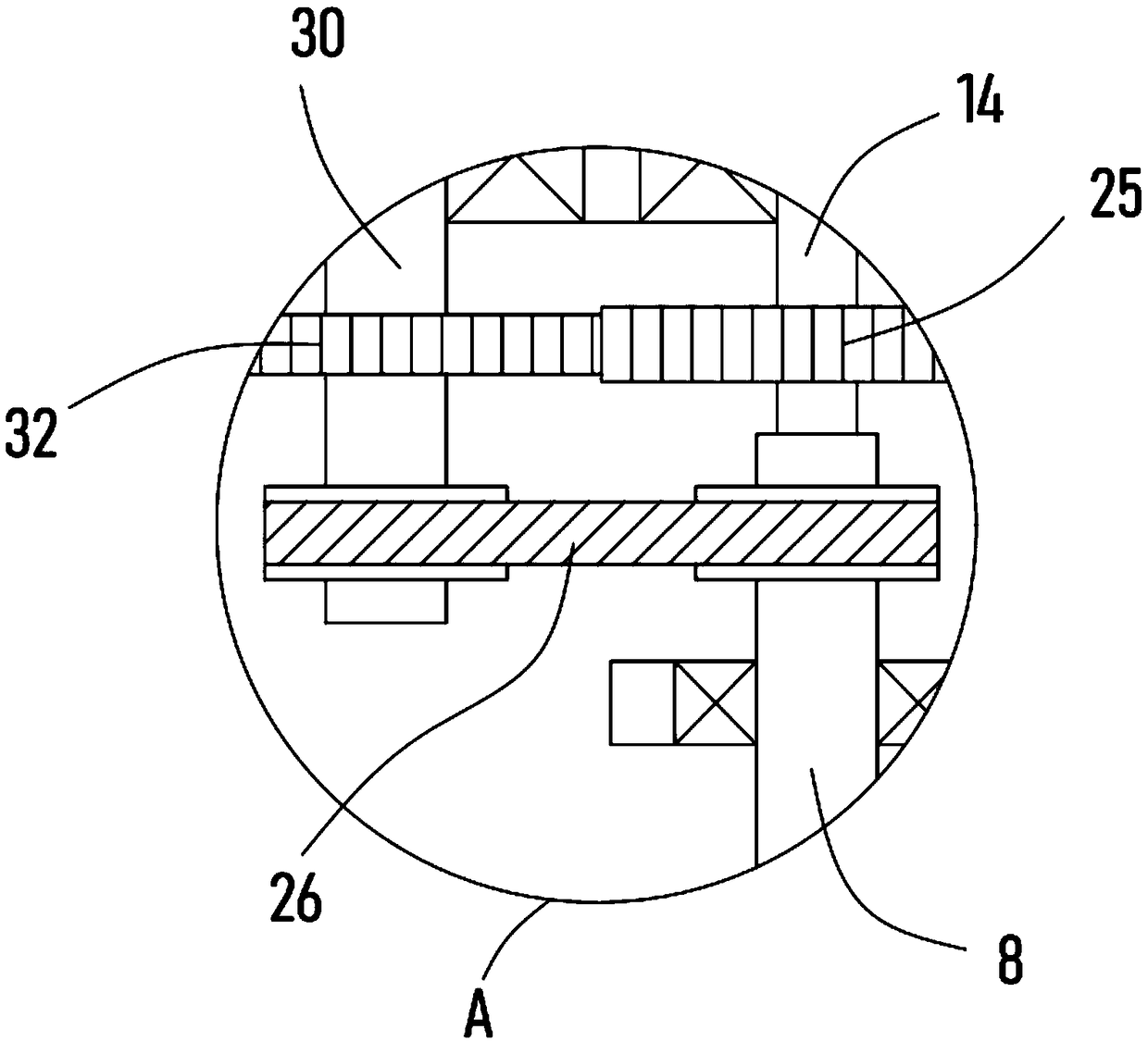

[0022] The output shaft of the stirring motor 11 is fixed with a driving shaft 30, and the top plate 10 is rotatably provided with a rotating sleeve 8 connected to the driving shaft 30 through a pulley mechanism 26, and the rotating sleeve 8 is rotatably provided with a driven shaft 14. The driven s...

Embodiment 2

[0026] On the basis of Embodiment 1, in addition, a servo motor 20 is fixedly installed on the bottom plate 1, the output shaft of the servo motor 20 is coaxially fixed with a driving pulley 19, and the side wall of the lifting column 13 is vertically fixed with a spur rack 15, which The tooth bar 15 left side rotation type is provided with the drive gear 16 that meshes with it, and the drive gear 16 is coaxially fixed with the driven pulley 17 that is connected with the driving pulley 19 through the drive belt 18 transmission, and the servo motor 20 can carry out forward rotation and Reversing is carried out alternately, and then the driving pulley 19 drives the driven pulley 17 to rotate together with the transmission gear 16 through the transmission belt 18, and the transmission gear 16 drives the top plate 10 to move up and down through the spur rack 15 meshing with it, thereby realizing the internal stirring frame. 6 and the outer stirring frame 7 rotate and stir the diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com