Novel sound-insulation self-leveling material as well as preparation method and application thereof

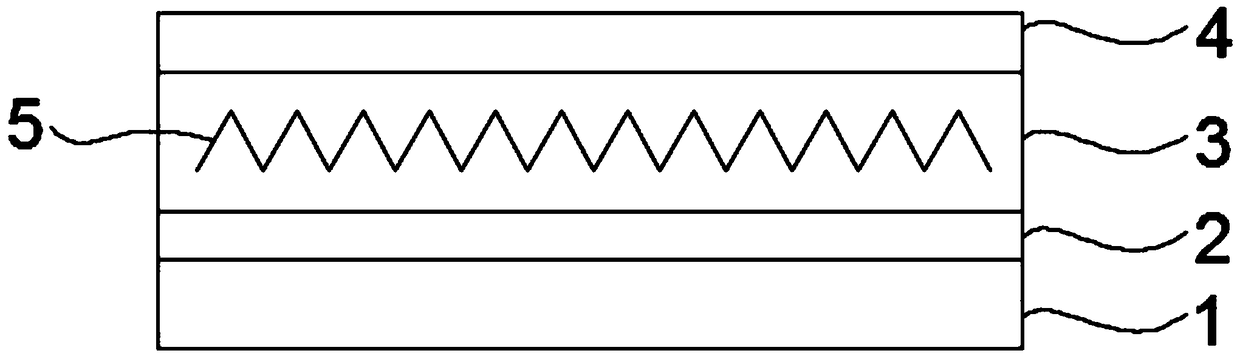

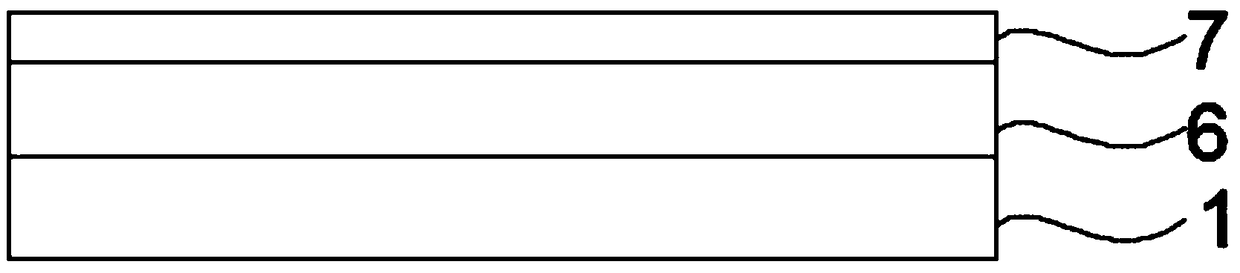

A new type of self-leveling technology, applied in the direction of sound insulation, insulation layer, building components, etc., can solve the problems of increasing living comfort, high cost, reducing cost, etc., to achieve good sound insulation performance, convenient floor decoration, and smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

[0025] A new type of sound-proof self-leveling material, its formula is as follows in terms of mass percentage: 15% pure benzene emulsion, 50% hollow glass microspheres, 34.95% quartz sand, 0.05% surfactant, and the diameter of the hollow glass microspheres is 60um , and the density of hollow glass microspheres is 120kg / m 3 , Surfactant selects Dow chemical surfactant Triton X-405 for use.

specific Embodiment example 2

[0027] A new type of sound-proof self-leveling material, its formula is as follows in terms of mass percentage: 12% pure benzene emulsion, 52% hollow glass microspheres, 35.95% quartz sand, 0.05% surfactant, and the diameter of the hollow glass microspheres is 60um , and the density of hollow glass microspheres is 120kg / m 3 , Surfactant selects Dow chemical surfactant Triton X-405 for use.

specific Embodiment example 3

[0029] A new type of sound-proof self-leveling material, its formula is as follows in terms of mass percentage: 17% pure benzene emulsion, 46% hollow glass microspheres, 36.93% quartz sand, 0.07% surfactant, and the diameter of the hollow glass microspheres is 60um , and the density of hollow glass microspheres is 120kg / m 3 , Surfactant selects Dow chemical surfactant Triton X-405 for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com