Accessory ingredient for tuning peg and preparation method thereof

A compounding agent and peg technology, applied in chemical instruments and methods, stringed instruments, lubricating compositions, etc., can solve problems such as easy to get dirty and difficult to control the dosage, and achieve the effects of accurate pronunciation, convenient tuning, and smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

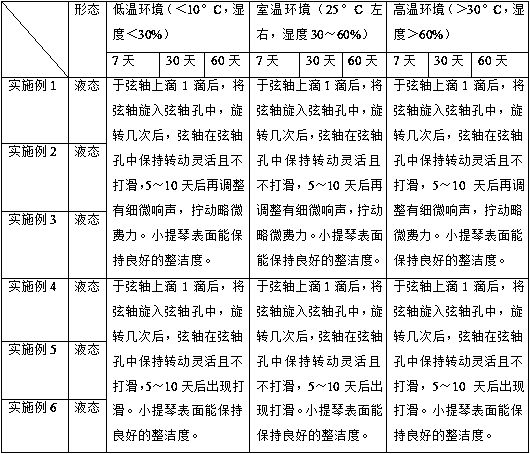

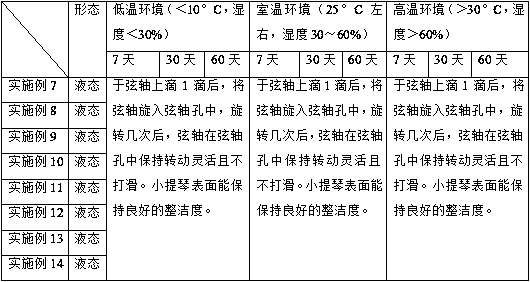

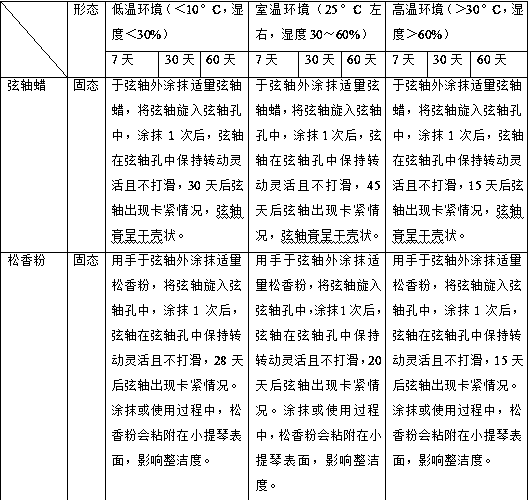

Examples

Embodiment 1

[0031] This embodiment relates to a peg matching agent. The peg compounding agent is a liquid viscous solution prepared after adding a gelling agent based on rosin resin and an organic solvent,

[0032] In the above-mentioned peg compound, the organic solvent is ethanol solution with a concentration ≥ 99%, the weight ratio of rosin resin to ethanol solution is 4:10, the gelling agent is carbomer, and the amount of carbomer added is 4% of the weight of the matrix. %.

[0033] In the present embodiment, the preparation method of peg compound comprises the following steps:

[0034] A, rosin resin is dissolved in ethanol solution in proportion, makes matrix solution;

[0035] B. Add carbomer in proportion to the matrix solution prepared in step A, stir evenly, and place at room temperature for 10 hours to prepare a peg compound with a viscosity of 4500cP.

Embodiment 2

[0037] This embodiment relates to a peg matching agent. The peg compounding agent is a liquid viscous solution prepared after adding a gelling agent based on rosin resin and an organic solvent,

[0038] In the above-mentioned peg compound, the organic solvent uses ethanol solution with a concentration ≥ 99%, the weight ratio of rosin resin to ethanol solution is 6:10, the gelling agent uses carbomer, and the amount of carbomer added is 10% of the weight of the matrix. %.

[0039] In the present embodiment, the preparation method of peg compound comprises the following steps:

[0040] A, rosin resin is dissolved in ethanol solution in proportion, makes matrix solution;

[0041] B. Add carbomer in proportion to the matrix solution prepared in step A, stir evenly, and place at room temperature for 10 hours to prepare a peg compound with a viscosity of 8000cP.

Embodiment 3

[0043] This embodiment relates to a peg matching agent. The peg compounding agent is a liquid viscous solution prepared after adding a gelling agent based on rosin resin and an organic solvent,

[0044] In the above peg compound, the organic solvent is ethanol solution with a concentration ≥ 99%, the weight ratio of rosin resin to ethanol solution is 5:10, the gelling agent is carbomer, and the amount of carbomer added is 6% of the weight of the matrix. %.

[0045] In the present embodiment, the preparation method of peg compound comprises the following steps:

[0046] A, rosin resin is dissolved in ethanol solution in proportion, makes matrix solution;

[0047] B. Add carbomer in proportion to the matrix solution prepared in step A, stir evenly, and place at room temperature for 10 hours to prepare a peg compound with a viscosity of 6500cP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com