Optimal control method of nemadectin fermentation impurity

An optimized control and impurity technology, applied in the biological field, can solve the problem of high removal cost in the extraction section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 150m 3 Fermentation tank process control:

[0047] Seed age: 66 hours

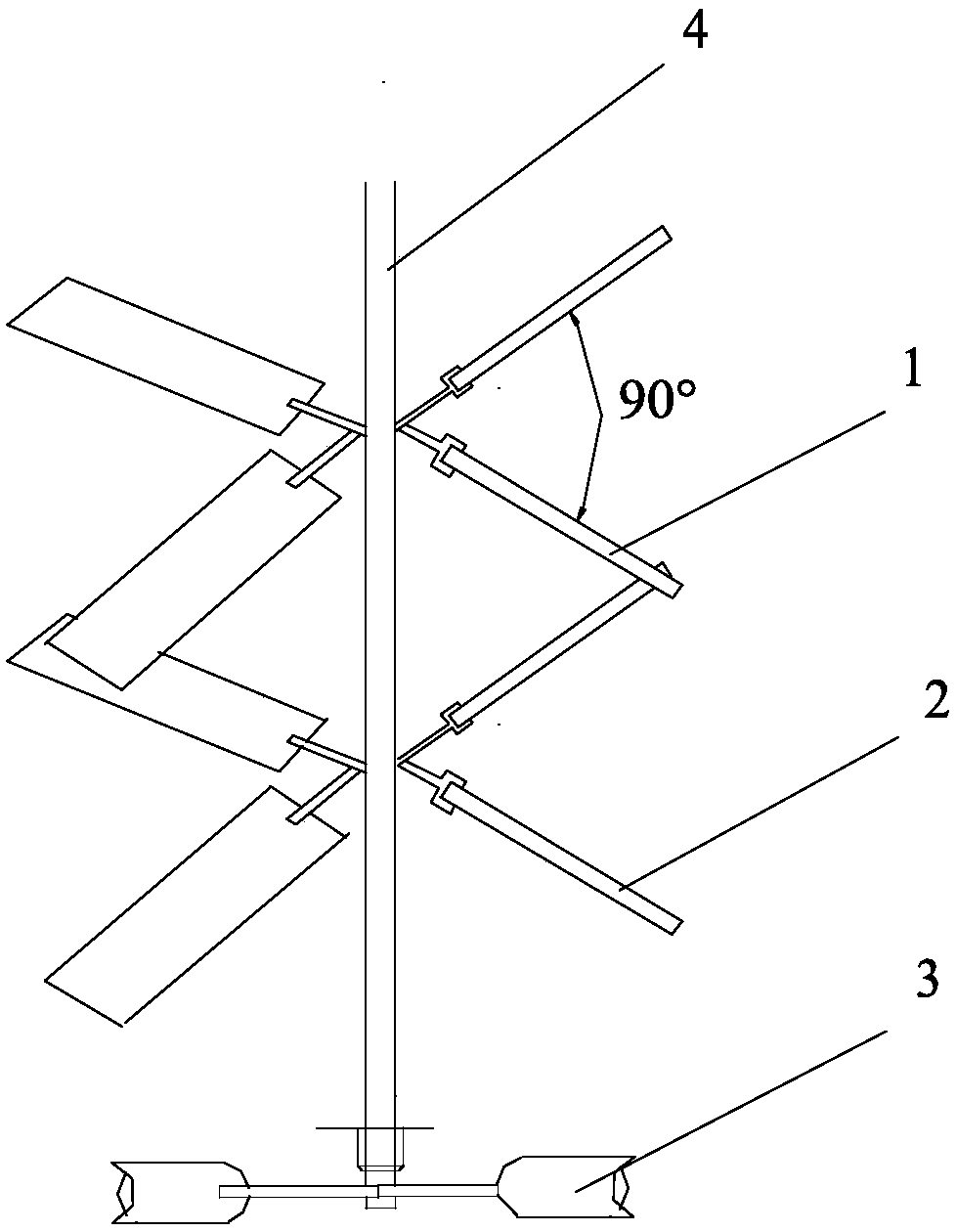

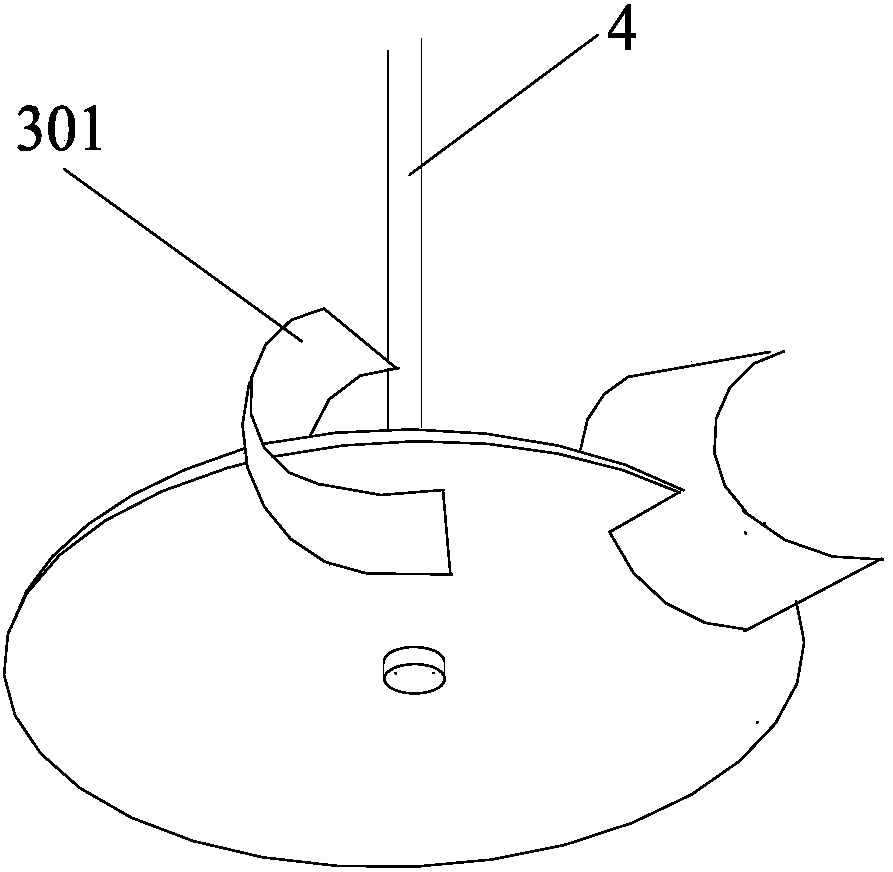

[0048] see figure 1 , the type of agitator in the fermenter: top four wide paddles 1+ middle four wide paddles 2+ bottom parabolic reverse installation (in the prior art, the protruding blades are opposite to the direction of rotation), the top agitator is about 4 on the stirring shaft 70% of the height; the four wide paddles 2 in the middle are located at 35% of the height, and the bottom is welded to install 8 stirring blades on the horizontal disc. figure 2 It is a schematic diagram of the installation of two parabolic blades 301 on a horizontal disc (other blades are not shown). The stirring paddle at the bottom of the agitator in the fermenter is a parabolic blade, and the parabolic convex part faces the direction of stirring, that is, the clockwise direction of the top view angle.

[0049] The parameters of the fermentation process are listed in Table 1.

[0050] Table 1: Example 1 ferme...

Embodiment 2

[0055] 150m 3 Fermentation tank process control:

[0056] Seed age: 65 hours.

[0057] Stirring type of fermenter: four wide paddles at the top + four wide paddles in the middle + parabolic reverse installation at the bottom. The parameters of the fermentation process are shown in Table 2.

[0058] Table 2: Example 2 fermentation parameters

[0059] peh h

Ventilation ratio vvm

Speed rpm

Dissolved oxygen%

A1 impurity ratio%

after planting

1:0.25

30

100

10

1:0.60

40

66

16

1:0.60

80

48

22

1:0.70

100

46

31

1:0.70

90

60

46

1:0.70

90

68

70

1:0.70

90

76

94

1:0.70

90

81

2.6

142

1:0.49

56

79

2.0

166

1:0.49

56

84

2.2

190

1:0.49

56

86

1.9

262

1:0.37

39

76

1.8

286

1:0.37

39

77

1.6

310

1:0.37

39

75

1.5

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com