Device and method for detachable manual assembling steel column

A dismantling, steel column technology, applied in the field of construction equipment, can solve the problems of affecting railway traffic safety, inconvenient disassembly and installation, waste of manpower, etc., to achieve the effect of improving construction efficiency and construction quality, facilitating disassembly and installation, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

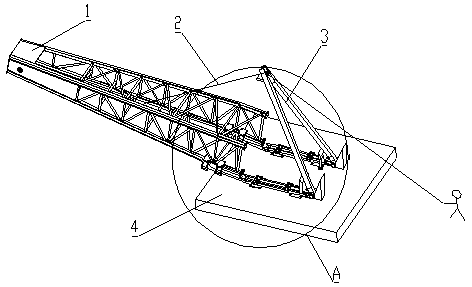

[0053] see Figure 1 to Figure 7 According to the needs of on-site construction, steel columns are divided into various models according to length and capacity, mainly including G200-13, G250-13, G250-15, G300-15, G350-15, G450-15 and other models. The weight of the steel column has the greatest impact on the construction of the steel column assembly. The weight of the steel column is summarized in the table below according to the Tonghua diagram.

[0054]

[0055]

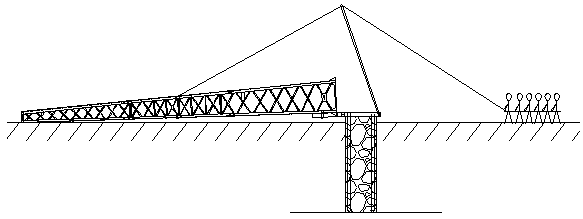

[0056] The main device of manual steel erection adopts a detachable design. After the construction personnel arrive at the site, they will install the artificial steel column erection device and prepare for steel column erection. Manual erection of steel columns at the construction site such as figure 1 shown.

[0057] According to the actual situation of the artificial steel column erection site, the mechanical analysis of the mathematical model of the artificial erection steel column construction is carr...

Embodiment 2

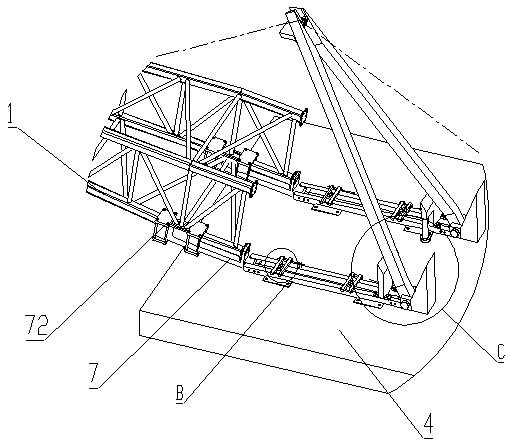

[0108] On the basis of Embodiment 1, the support 3 is an inverted V-shaped support; the support 3 includes two straight rods, the upper ends of the two straight rods are fixedly connected to the vertical parts on both sides of a U-shaped ring, and the middle part of the U-shaped ring is provided with scroll wheel;

[0109] The side of the bracket 3 facing the steel column 1 is provided with a boss 31, the boss 31 is arranged on the lower side of the top of the bracket 3, and the angle between the upper surface of the boss 31 and the upper part of the bracket 3 is 60°. The boss 31 can be used to push the bracket 3 to rotate by pushing the boss 31 if the steel column 1 may touch the bracket 3 when it stands up. And because of the function of the boss 31, it can prevent the sling 2 from being caught by the steel column 1 and the bracket 3 and cause jamming. At the same time, the angle between the boss 31 and the bracket 31 is more helpful for the steel column 1 to push the bracke...

Embodiment 3

[0112] On the basis of Embodiment 1 or 2, the stopper 73 of the connecting part 7 is provided with a turning roller. The axis of the rotating roller is perpendicular to the direction in which the connecting part 7 rotates, and the effect of the rotating roller is to make it slide down from the stopper 73 more easily when the steel column stands up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com