Load maintaining control valve

A load holding and control valve technology, applied in fluid pressure actuating devices, servo motor components, mechanical equipment, etc., to solve problems such as poor holding effect, difficulty in completely isolating the pilot spool valve from the main valve, and controlling oil circuit leakage. , to reduce the number of parts, facilitate promotion and use, and avoid the effect of sliding valve cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

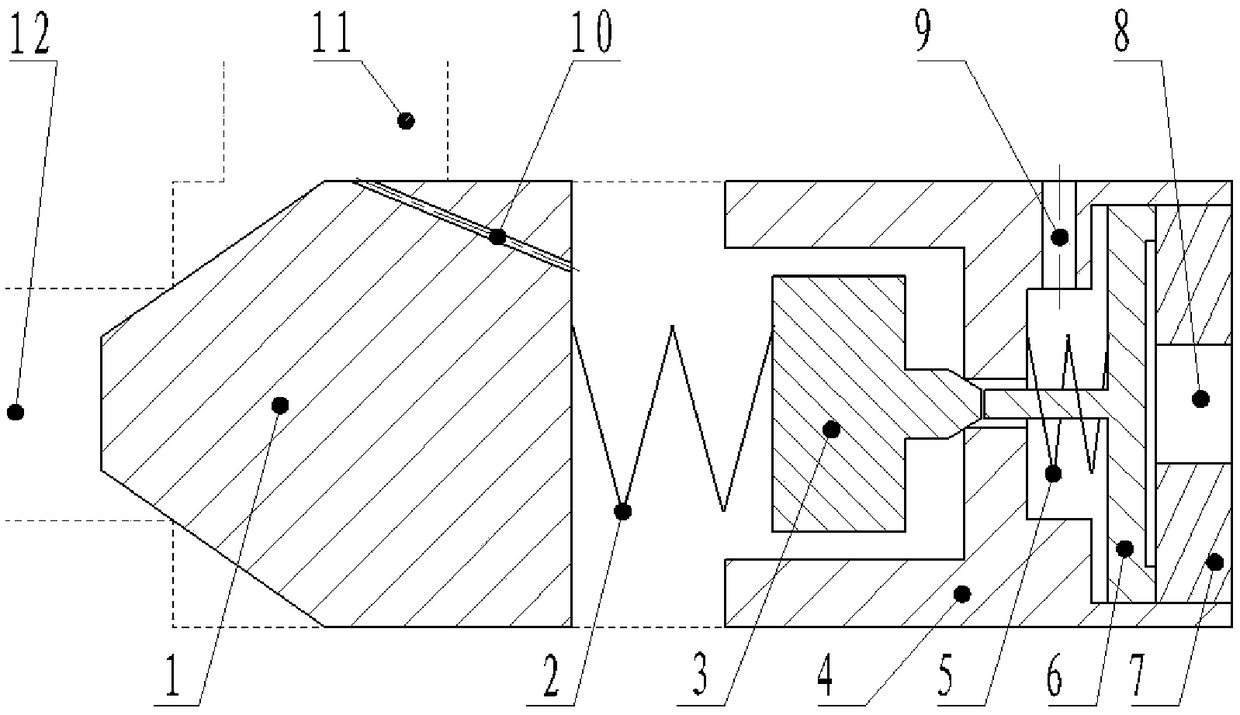

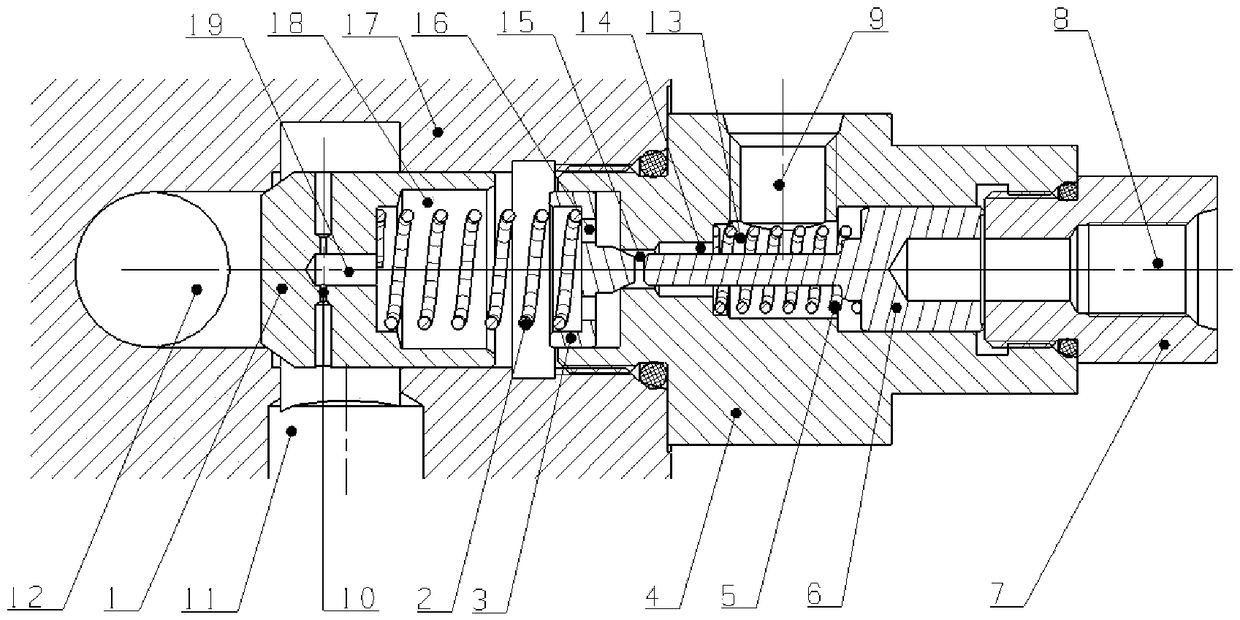

[0020] Embodiment 1 of the present invention discloses a double-cone sealed load-holding control valve. The control valve adopts pilot control and a plug-in structure, specifically as figure 2 As shown, including: 1-main spool, 2-main spring, 3-control spool, 4-control valve body, 5-pilot spring, 6-pilot push rod, 7-limit joint, 8-pilot oil port , 9-oil drain port, 10-throttle hole, 11-holding oil port, 12-oil inlet hole, 15-control valve hole, 16-oil hole and 17-installation valve body, wherein the valve is inserted On the 17-installation valve body, and 11-maintain oil port and 12-oil inlet hole are the oil ports on the 17-installation valve body. 1-The conical surface of the main valve core is in contact with the sealing surface between the 12-oil inlet port and 11-maintaining oil port of the valve body installed on 17-to form the conical surface sealing structure of the main valve port; 3-The cylindrical guide section of the control spool Cooperate with the guide hole at...

Embodiment 2

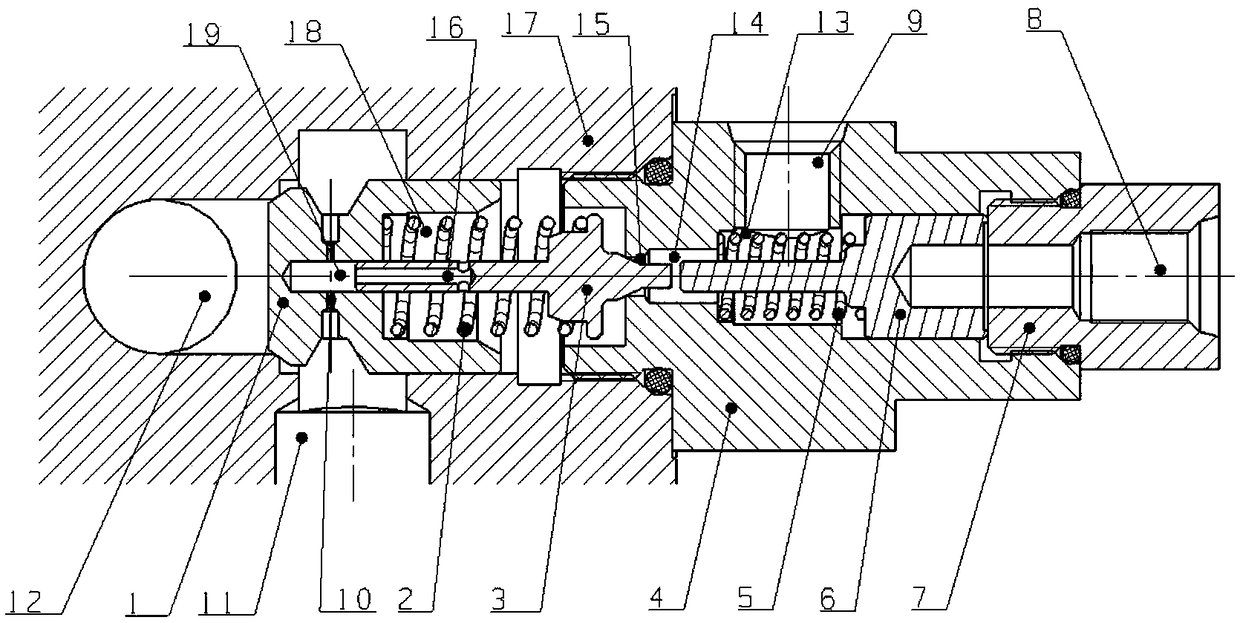

[0024] Embodiment 2 of the present invention discloses a double-cone sealed load-holding control valve. The control valve adopts pilot control and a plug-in structure, specifically as image 3 As shown, including: 1-main spool, 2-main spring, 3-control spool, 4-control valve body, 5-pilot spring, 6-pilot push rod, 7-limit joint, 8-pilot oil port , 9-Oil drain port, 10-Throttle hole, 11-Holding oil port, 12-Oil inlet hole, 13, 18-Second spring chamber, 14-19-Second oil passage hole, 15-Control valve hole , 16-oil hole and 17-installation valve body, wherein the valve is inserted on the 17-installation valve body, and 11-holding oil port and 12-oil inlet hole are the oil ports on the 17-installation valve body . 1-The conical surface of the main valve core is in contact with the sealing surface between the 17-installation valve body 12-the oil inlet hole and 11-the maintenance oil port to form the conical surface sealing structure of the main valve port; 3-The left end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com