Heating valve control system and segmented control method thereof

A technology of valve control and segmental control, applied in heating systems, central heating components, central heating sensors, etc., can solve problems such as temperature control hysteresis, achieve the effects of reducing regulation cycles, solving temperature control hysteresis, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to better understand the present invention, the specific implementation manners of the present invention will be explained in detail below in conjunction with the accompanying drawings and application examples.

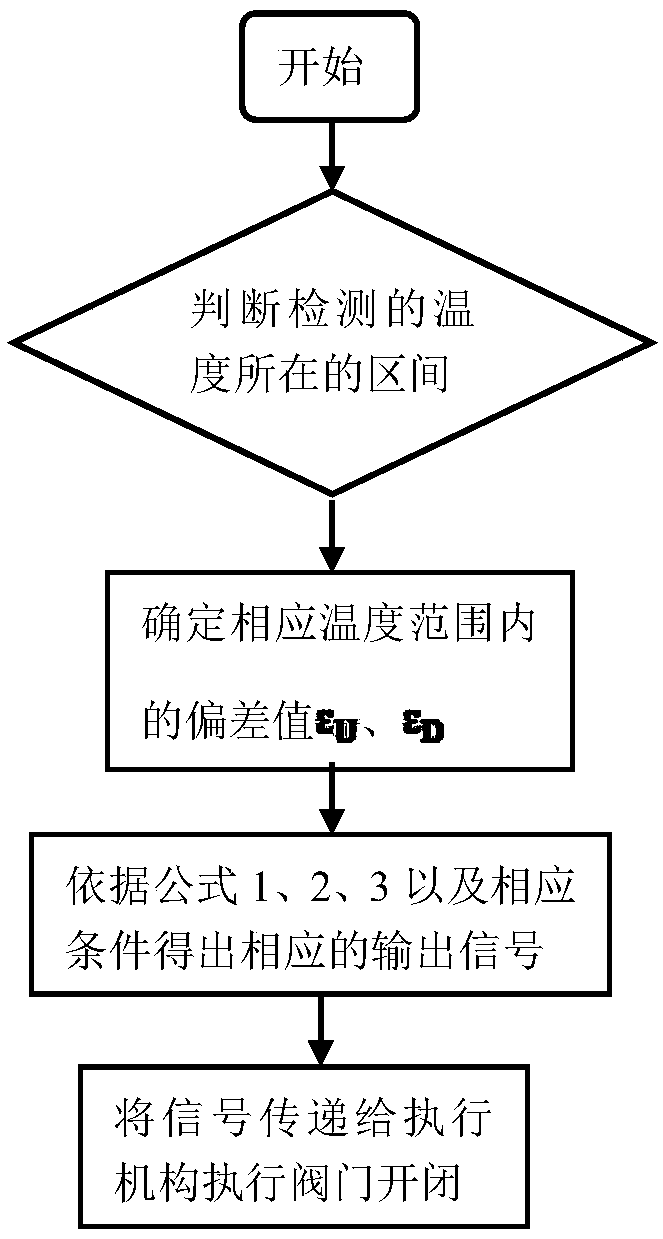

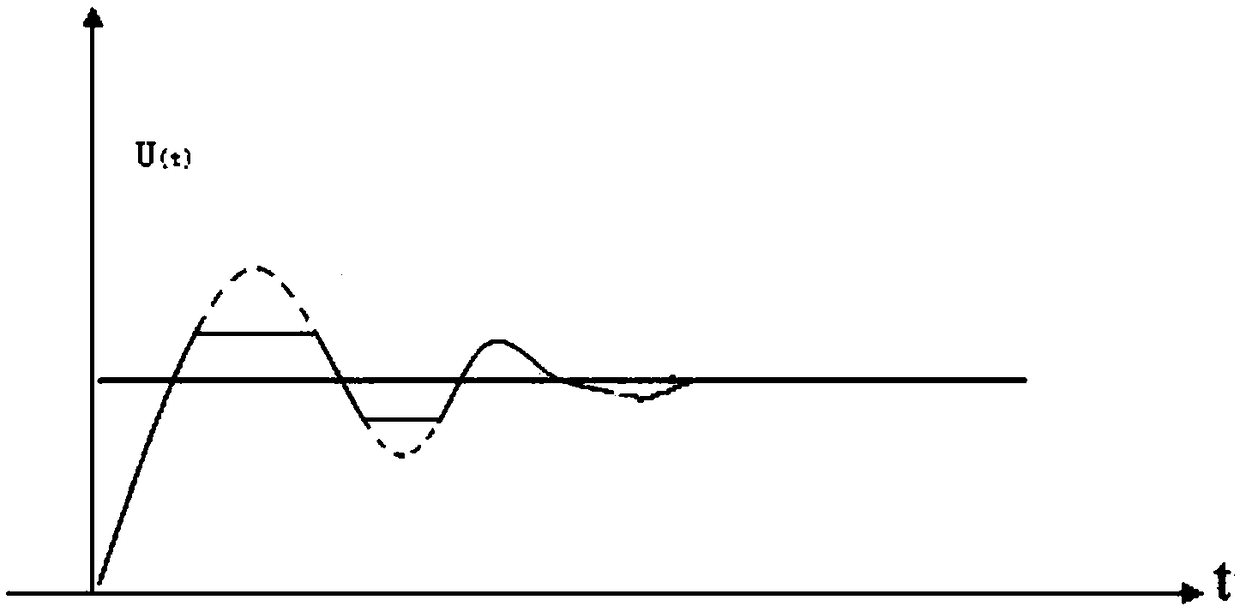

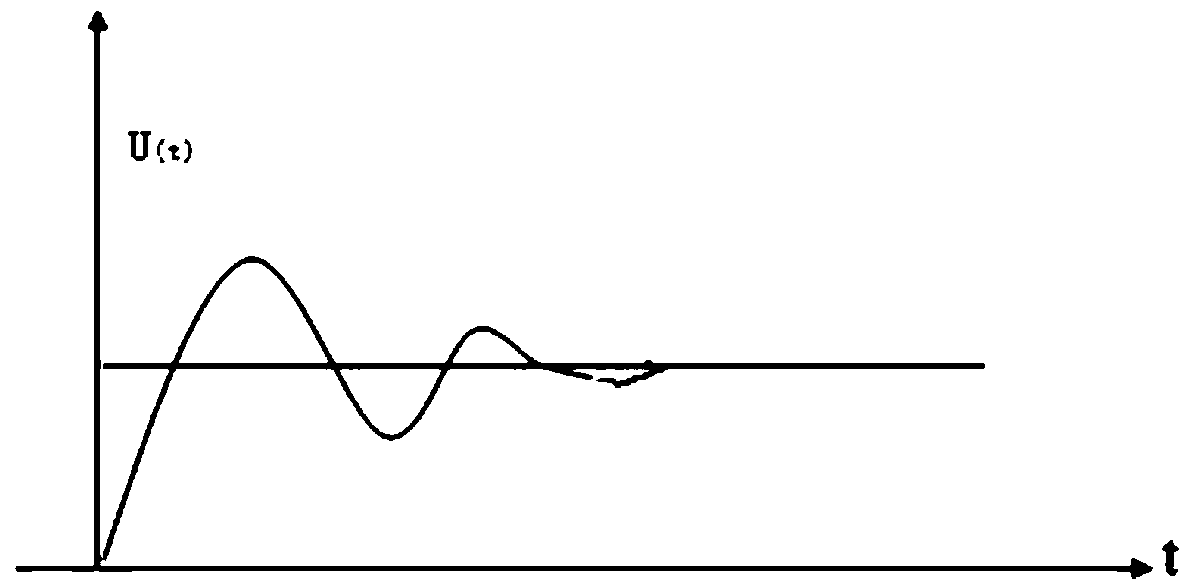

[0046] The original PID adjustment mode is a single valve opening range, the formula used is as follows, and the control graph is as follows image 3 :

[0047]

[0048] u (t) : Regulator output signal

[0049] e(t): deviation signal

[0050] k P : Scale factor

[0051] I τ :Integration time

[0052] T D : Derivative time

[0053] That is to say, no matter what the water supply temperature is, the upper and lower deviations of its adjustment are the same fixed value, and the valve adjustment range will be large, and the adjustment period will be long, resulting in lagging temperature control.

[0054] A heating valve control system and a segmented control method provided by the present invention divide the supply water temperature into stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com