Gas-solid coupling coal sample wave velocity anisotropism detection device and method

An anisotropy, detection device technology, applied in measurement devices, using sonic/ultrasonic/infrasonic waves to analyze solids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. The actual state of the coal body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below.

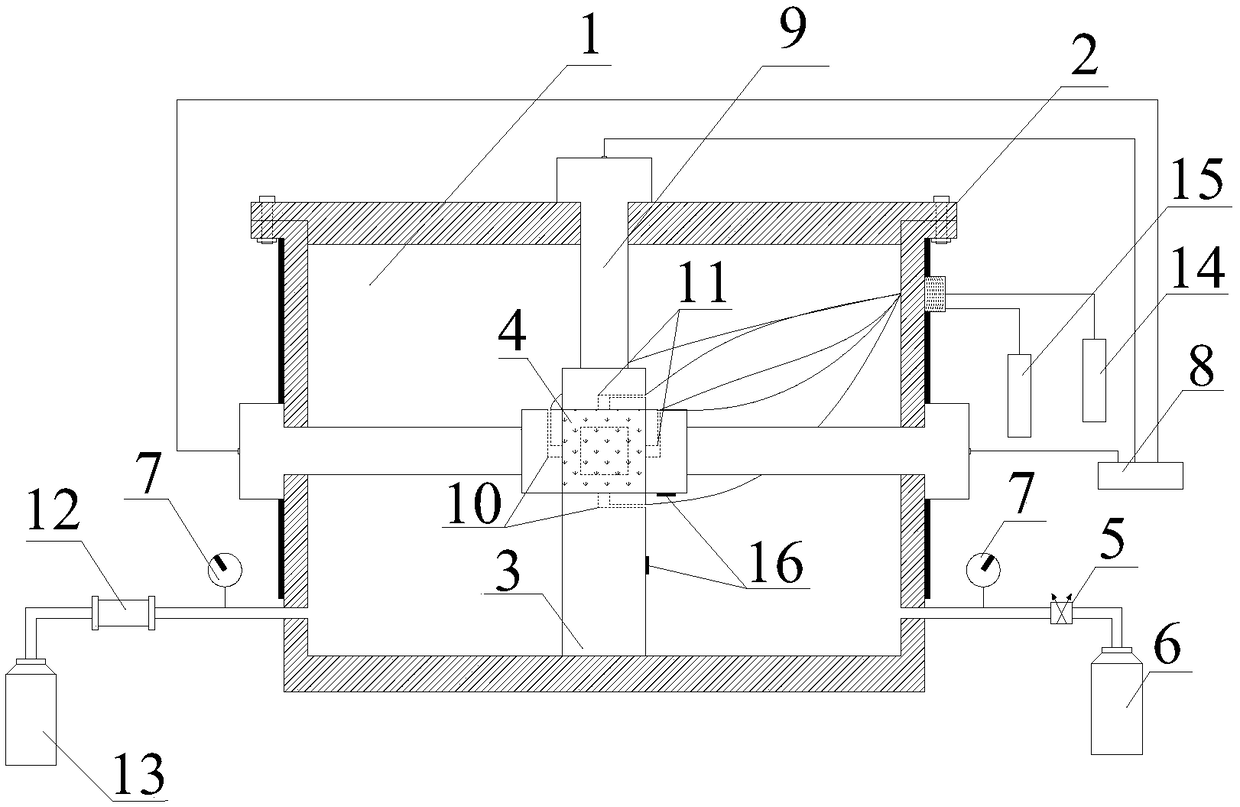

[0027] As shown in the figure, a gas-solid coupled coal sample wave velocity anisotropy detection device includes a pressure chamber 1, a gas transmission system, a coal sample placement platform 3, a true triaxial pressurization system 8, a transducer group and Sonicometer 14,

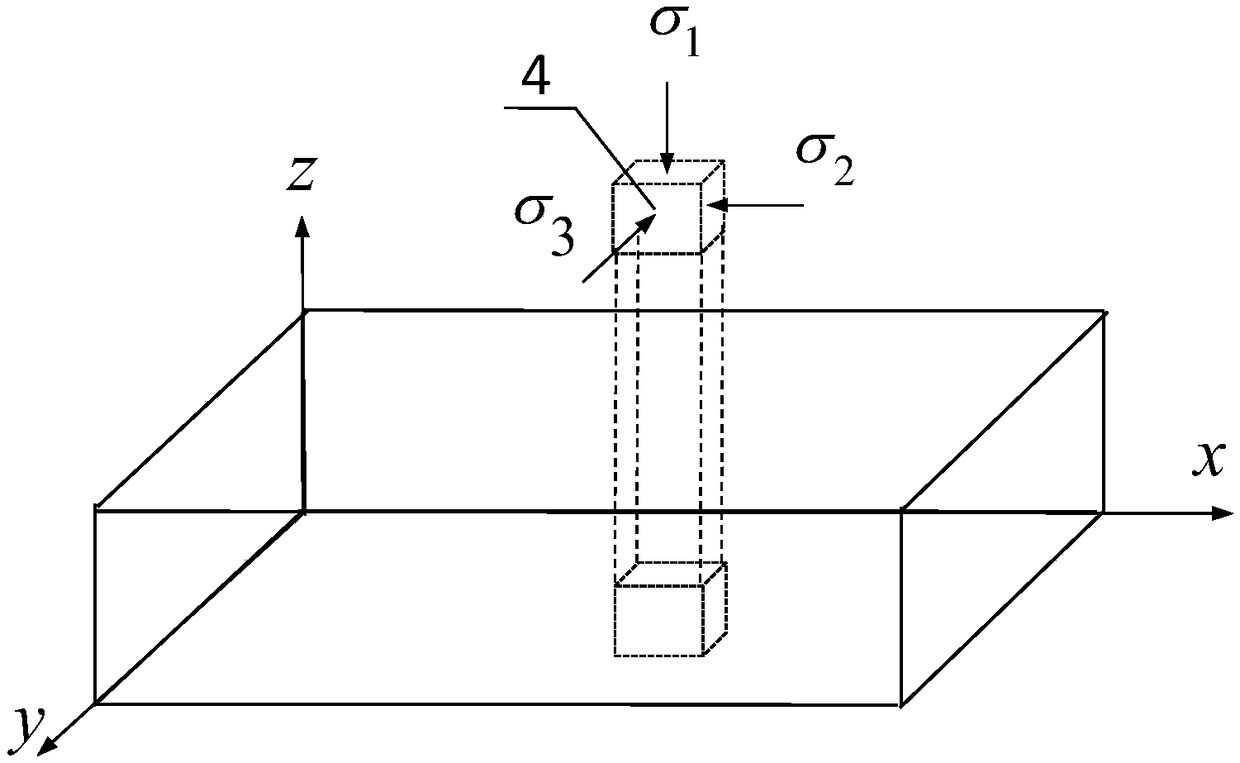

[0028] The pressure chamber 1 is composed of a pressure container with an open upper part and a piston top cover 2, the piston top cover 2 is sealed and fixed at the opening of the pressure container, and the coal sample placement platform 3 is fixed in the pressure container. The coal sample 4 is placed on the coal sample placement platform 3, and the test coal sample 4 is a cube;

[0029] A plurality of axial compression rods 9 of the true triaxial pressurization system 8 respectively pass through the side wall of the pressure container and the piston top cover 2 to contact the four sides and the top surface of the test coal sample 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com