Welder workload assessment client, server, system and method

A workload and client-side technology, applied in the field of data statistics, can solve problems such as no unified standard workload accounting method, complicated welding operations, and difficulty in accurate statistics and control of product welding progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

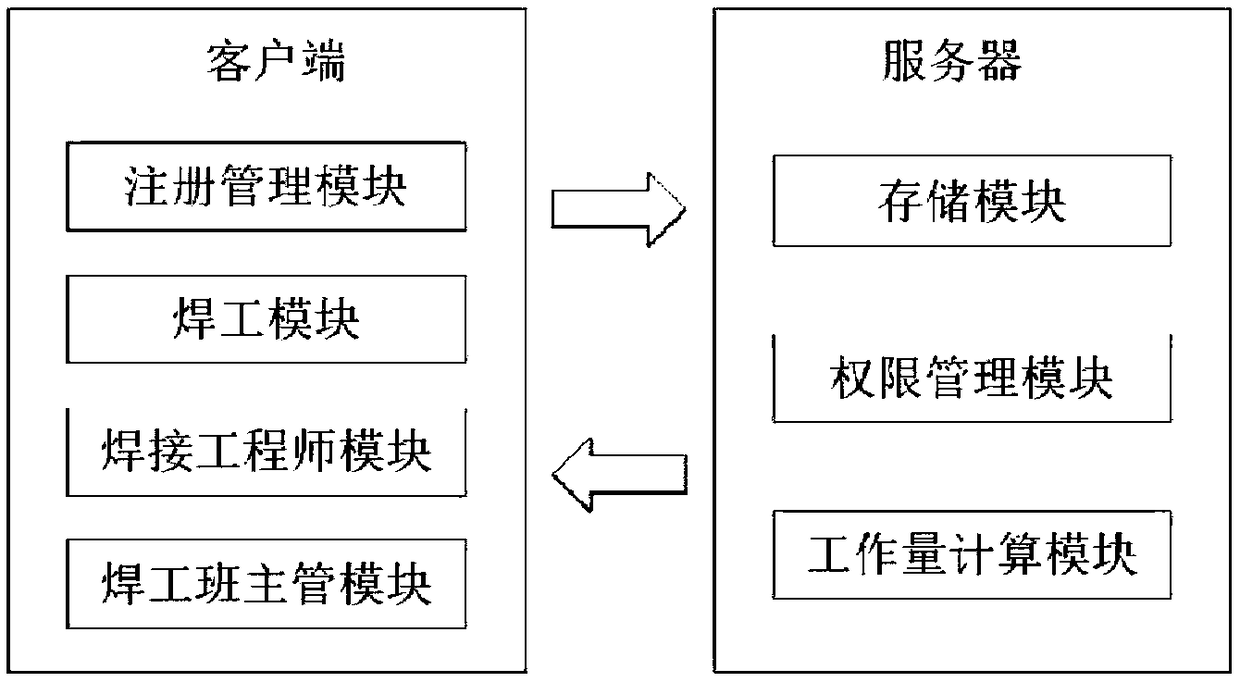

[0048] This embodiment discloses a welder workload assessment system, including a client and a server.

[0049] Client, including registration management module, welder module, welding engineer module and welder supervisor module. in,

[0050] Registration management unit, when users log in to the system for the first time, they need to enter basic personal information and send it to the server;

[0051] The welder module is used to input the product to be welded, the operation to be welded and the welding plan, generate a requisition form and send it to the welding engineer module; the requisition form also includes corresponding welder information.

[0052] The welding engineer module is used to review the received requisition form, and send a welding materials requisition notice to the welder module if the requisition is passed; at the same time, send the requisition form and corresponding welder information to the server.

[0053] The welder shift supervisor module is us...

Embodiment 2

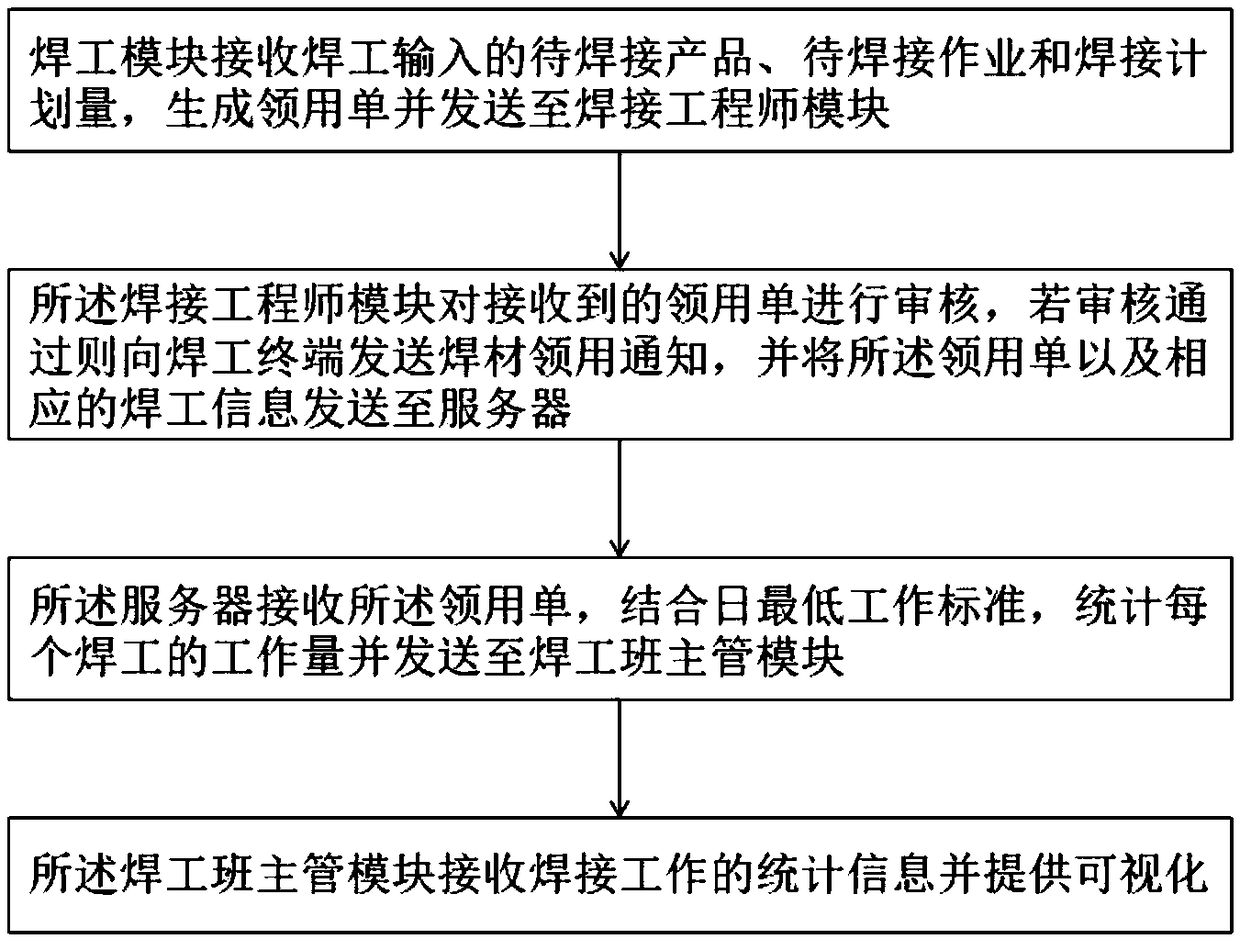

[0068] The purpose of this embodiment is to provide a welder workload assessment method, including the following steps:

[0069] The welder module receives the product to be welded, the operation to be welded and the welding plan input by the welder, generates a receipt and sends it to the welding engineer module;

[0070] The welding engineer module reviews the received requisition form, and if it passes the review, sends a welding material requisition notification to the welder terminal, and sends the requisition form and corresponding welder information to the server;

[0071] The server receives the receipt, combines the daily minimum work standard, counts the workload of each welder and sends it to the welder class supervisor module;

[0072] The welder supervisor module receives welding job statistics and provides visualization.

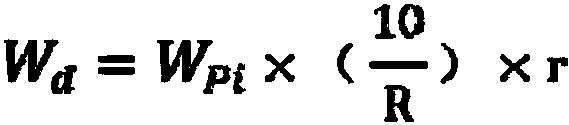

[0073] The daily workload calculation method is:

[0074]

[0075] Among them, W d is the workload of the welder on the day, r is the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com