A high-voltage protective circuit breaker

A technology for high-voltage protection and circuit breakers, which is applied in the direction of protection switches, emergency protection devices, and parts of protection switches. Fast speed, improved service life, and improved practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

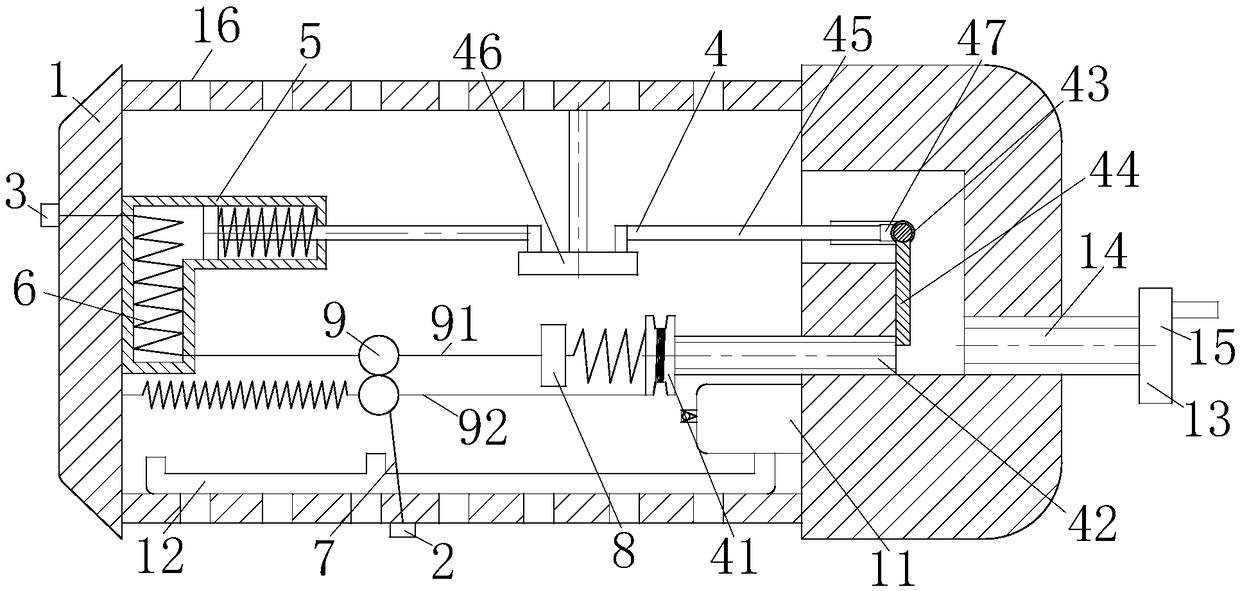

[0016] use Figure 1-Figure 2 The structure of the high voltage protection circuit breaker which concerns on one Embodiment of this invention is demonstrated as follows.

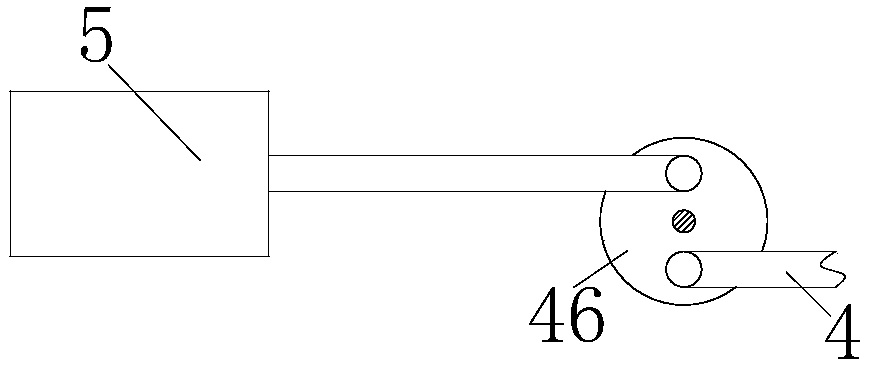

[0017] Such as figure 1 and figure 2As shown, a high voltage protective circuit breaker according to the present invention includes a housing 1, an input terminal 2, an output terminal 3, a circuit breaking module 4, a cylinder 5, an output line 6, an input line 7, a fixing plate 8 and a metal ball 9 The input terminal 2 is arranged on the outer wall of the bottom of the housing 1; the output terminal 3 is arranged on the outer wall of the left side of the housing 1; , the breaking module 4 is used to control the breaking of the circuit breaker; the cylinder 5 is installed on the left inner wall of the housing 1, the cylinder 5 is L-shaped, and mercury is installed in the cylinder on the left side of the cylinder 5, and the mercury expands easily when heated to provide power for the cylinder 5 , the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com