A kind of preparation method of carbon-coated ternary positive electrode material

A positive electrode material and carbon coating technology, which is applied in the field of preparation of carbon-coated ternary positive electrode materials, can solve the problem that ternary positive electrode materials are easily reduced by carbon, etc. Effect of magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A novel carbon-coated nickel-cobalt-manganese ternary cathode material, the preparation method of which is:

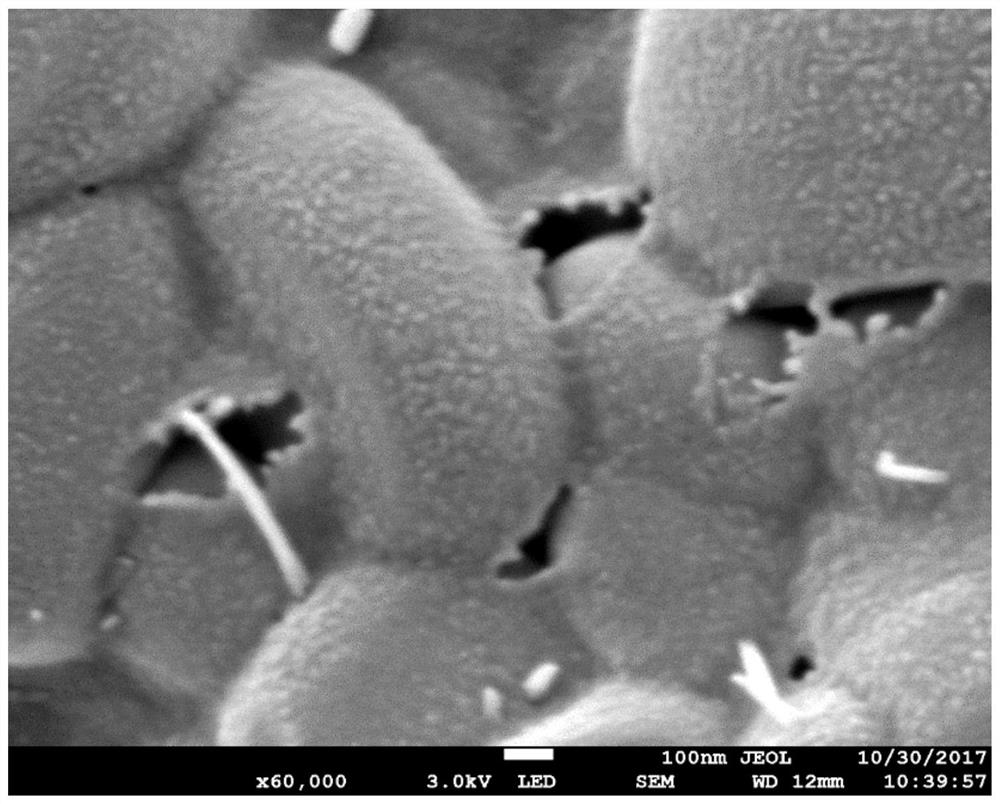

[0052] Step 1, the prepared NCM622, i.e. Li(Ni 0.6 co 0.2 mn 0.2 )O 2 As the matrix material, mix the bare ternary material and ethyl orthosilicate (converted into silicon dioxide) in the ethanol phase at a mass ratio of 1:0.01, stir at 60°C for 3 hours, and slowly add a certain amount of deionized Water, react at 800r / min for 3 hours, then heat up to 100°C to send out all the solvents, scrape off the powder and sinter in air at 500°C for 5 hours, and then cool to obtain a silica-coated ternary material, denoted as SiO 2 @NCM.

[0053] Step 2, use the silica-coated ternary material in the experimental step 1, add it to 5% glucose aqueous solution, heat and stir, evaporate to dryness, and then put it into a tube furnace at 800°C for sintering in a nitrogen atmosphere for 3 hours, A double-coated ternary material of silica and carbon, denoted as C / SiO 2 @NCM. ...

Embodiment 2

[0057] A novel carbon-coated nickel-cobalt-manganese ternary cathode material, the preparation method of which is:

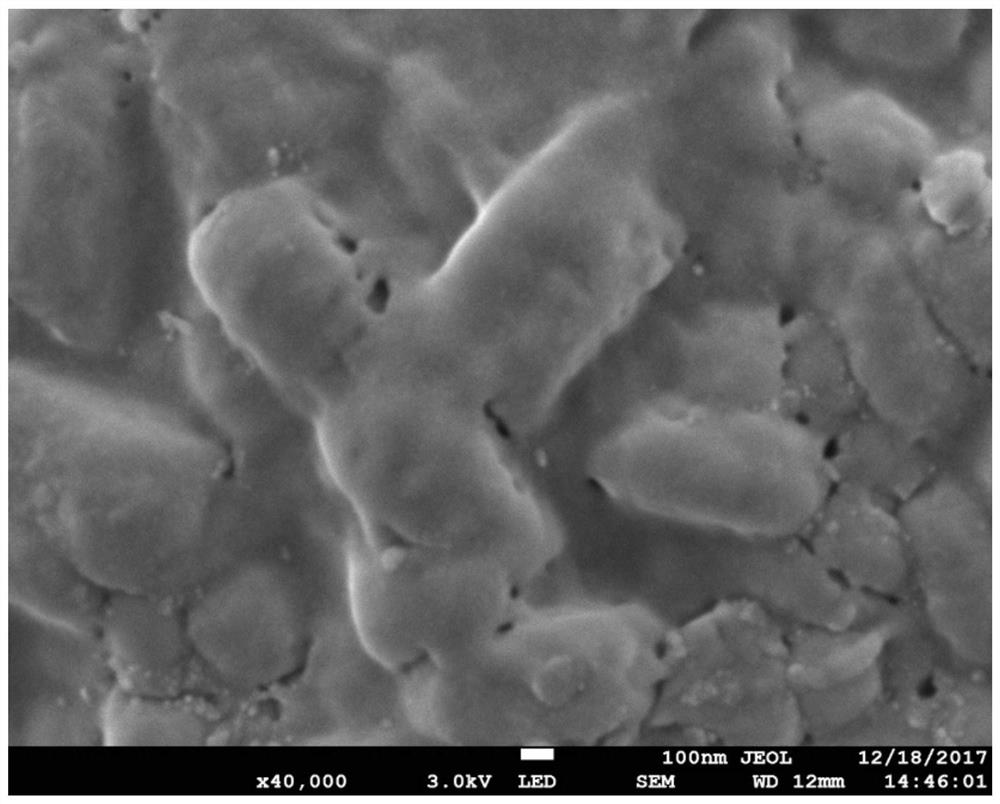

[0058] Step 1: Take the prepared NCM622 as the base material, mix the bare ternary material and silicon tetrachloride (converted into silicon dioxide) in the ethanol phase at a mass ratio of 1:0.005, stir at 20°C for 7 hours, and then mix it according to the chemical Add a certain amount of deionized water dropwise at a metering ratio, react at 800r / min for 3 hours, then heat up to 100°C to emit all the solvent, scrape off the powder and sinter in air at 200°C for 8 hours, and then cool to obtain a silica coating Covered ternary material, denoted as SiO 2 @NCM.

[0059] Step 2: Use the silicon oxide-coated ternary material in the experimental step 1, add it to 1% glucose aqueous solution, heat and stir, evaporate to dryness, and then put it into a tube furnace at 100°C for sintering in a nitrogen atmosphere for 20 hours. A double-coated ternary material of sil...

Embodiment 3

[0063] A novel carbon-coated nickel-cobalt-manganese ternary cathode material, the preparation method of which is:

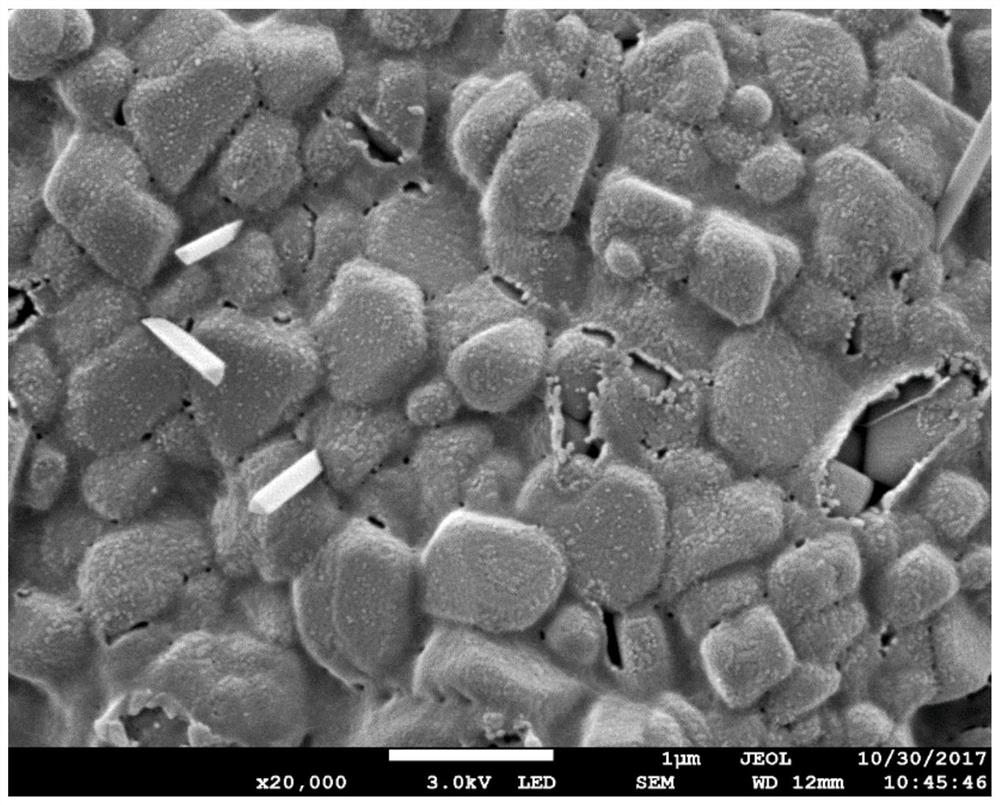

[0064] Step 1. Using the prepared NCM622 as the base material, mix the bare ternary material and silica particles in the methanol phase at a mass ratio of 1:0.02, stir at 80°C for 2 hours, and then add a certain amount of Ionized water, react at 800r / min for 3 hours, then heat up to 100°C to send out all the solvent, scrape off the powder and sinter in air at 700°C for 2h, and then cool to obtain a silica-coated ternary material, which is denoted as SiO 2 @NCM.

[0065] Step 2. Use the silicon oxide-coated ternary material in the experimental step 1, add it to 10% glucose aqueous solution, heat and stir, evaporate to dryness, and then put it into a tube furnace at 1000°C for sintering under a nitrogen atmosphere for 1 hour. A double-coated ternary material of silicon oxide and carbon, denoted as C / SiO 2 @NCM.

[0066] Step 3. Put the material in the experime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com