Preparation method of pb/c supercapacitor battery negative electrode

A technology for supercapacitors and negative electrodes of batteries, applied in the field of energy storage devices, can solve the problems of accelerating the storage and release of electric energy by the pole pieces, poor infiltration of the pole pieces to the electrolyte, and low utilization rate of the negative electrode active material, so as to improve the conductivity of the electrodes. , Excellent adsorption performance, large specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

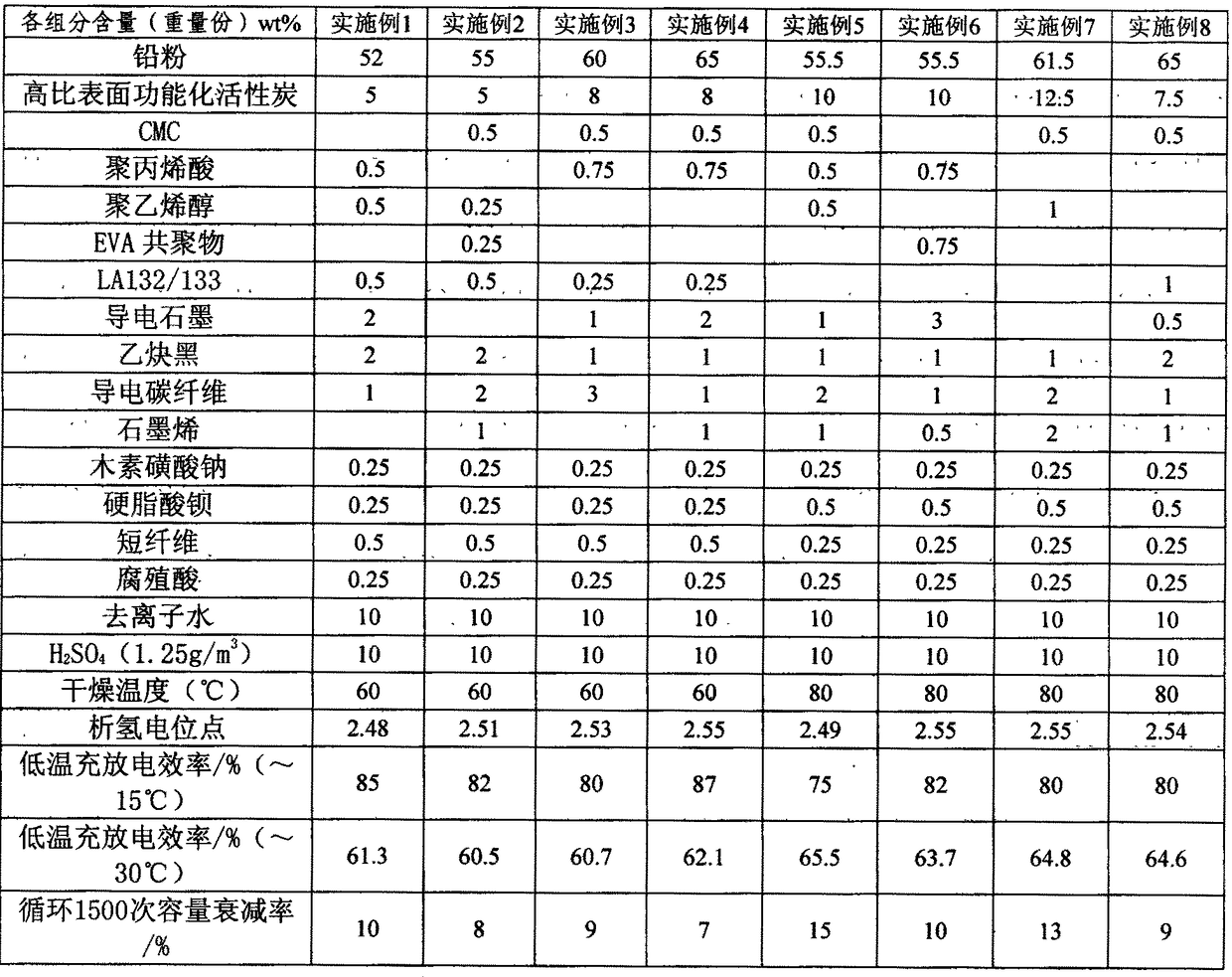

[0032] In the negative electrode formula of the energy storage type Pb / C supercapacitor battery: under normal temperature and pressure, according to the components specified in Table 1, the modified high specific surface functionalized activated carbon material slurry: 96.7kg, lead powder: oxidized 500kg with a degree of 75±2%, deionized water: 55kg, sodium lignosulfonate: 2kg, carbon black: 1.5kg, barium stearate: 1.0kg, short fiber: 1.5kg, 1.25g / cm 3 Sulfuric acid 52kg mixture enters and stirs in the vertical paddle mixer. Preparation of negative electrode paste by dry blending method: add lead powder and short fiber to a vertical paddle stirring paste machine and stir for 10 minutes, then add high specific surface modified activated carbon material slurry and stir for 15 minutes, and then within 15 to 20 minutes Slowly add sulfuric acid into the paste mixing machine, then add deionized water, the time is controlled within 15 minutes, and then stir for 20 minutes to obtain t...

Embodiment 2

[0034] The method of Experimental Example 1 was repeated at the contents of each combination specified in Table 1 below, and the test results are listed in Table 1.

[0035] In the negative electrode formula of power type Pb / C supercapacitor (device) battery: lead powder with oxidation degree of 75±2%: 500kg, deionized water: 65kg, short fiber: 1.5kg, sodium lignosulfonate: 1.5kg, carbon black : 1.75kg, barium stearate: 1.0kg, short fiber: 1.5kg, 1.25g / cm 3 Sulfuric acid 65kg, acetylene black: 3kg, conductive graphite: 2kg. Preparation of negative electrode paste by dry mixing method: add lead powder, acetylene black, conductive graphite and short fibers to a vertical paddle stirring paste mixing machine and stir for 10 minutes, then slowly add sulfuric acid into the paste mixing machine within 10 minutes, and then Add deionized water, control the time within 15 minutes, and then stir for 15 minutes to obtain a power type Pb / C supercapacitor (device) battery negative electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com