a fes 2-x the se x Sodium Ion Capacitors Made of Negative Electrode Material

A negative electrode material and capacitor technology, applied in the field of capacitors, can solve the problems of no reports, and achieve the effects of enhanced electronic conductivity, high current charging and discharging capacity, and fast diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] a FeS 2-x Se x A sodium ion capacitor whose material is a negative electrode material, the sodium ion capacitor includes a positive electrode sheet, a negative electrode sheet, a diaphragm, an electrolyte and a casing.

[0045] The mass ratio of the active material in the positive electrode sheet to the active material in the negative electrode sheet is controlled at 4:1, and the electrolyte is NaClO 4 Soluble in tetraethylene glycol dimethyl ether, NaClO 4 The concentration is 1mol / L; the diaphragm material is Whatman GF / F glass microfiber.

[0046] The negative electrode sheet is obtained by mixing the active material, conductive agent, and binder, adding a solvent, grinding it into a slurry, and coating it on copper foil; the active material in the capacitor negative electrode sheet is FeS 2-x Se x Materials, the conductive agent is acetylene black, the binder is polyvinylidene fluoride (PVDF), the solvent is methylpyrrolidone (NMP), the mass ratio of active mate...

Embodiment 2

[0061] a FeS 2-x Se x Material is the sodium ion capacitor of negative electrode material, as shown in embodiment 1, difference is:

[0062] FeS 2-x Se x The preparation method of material comprises steps as follows:

[0063] (1) 1mmol FeSO 4 ·7H 2 0.5mmol urea is dissolved in the mixed solvent of dimethylformamide and ethylene glycol, dimethylformamide 15mL, ethylene glycol 20mL in the mixed solvent, then add sublimation sulfur, selenium powder, obtain mixed solution; Sublimation sulfur and The total molar weight of selenium powder is 6.5mmol, and the molar ratio of sublimated sulfur and selenium powder is 1:9;

[0064] (2) The mixed solution was transferred to a stainless steel reactor and placed in an oven, and reacted at 170°C for 22 hours;

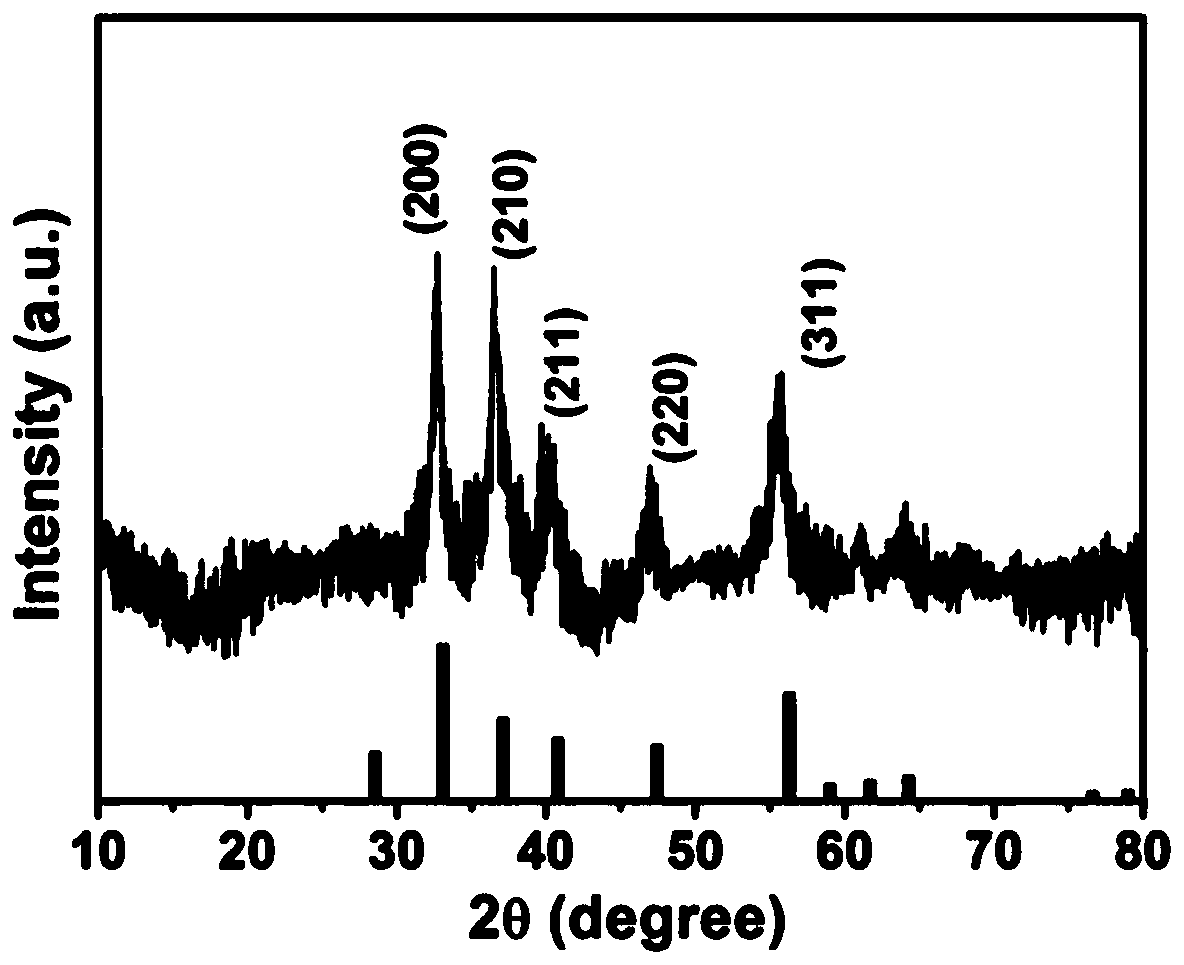

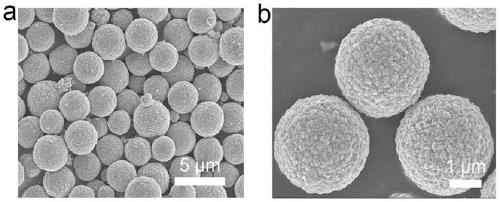

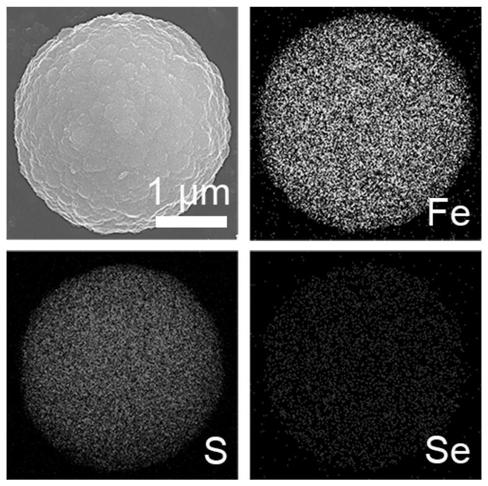

[0065] (3) The product was centrifuged, washed several times with ethanol and water, and dried in a vacuum oven at 50°C for 16 hours, and FeS was successfully obtained 2- x Se x (x=0.2) Microspheres. FeS produced 2-x Se ...

Embodiment 3

[0067] a FeS 2-x Se x Material is the sodium ion capacitor of negative electrode material, as shown in embodiment 1, difference is:

[0068] FeS 2-x Se x The preparation method of material comprises steps as follows:

[0069] (1) 1mmol FeSO 4 ·7H 2 0.5mmol urea is dissolved in the mixed solvent of dimethylformamide and ethylene glycol, dimethylformamide 15mL, ethylene glycol 20mL in the mixed solvent, then add sublimation sulfur, selenium powder, obtain mixed solution; Sublimation sulfur and The total molar weight of selenium powder is 6.5mmol, and the molar ratio of sublimated sulfur and selenium powder is 1:9;

[0070] (2) The mixed solution was transferred to a stainless steel reaction kettle and placed in an oven, and reacted at 180°C for 20h;

[0071] (3) The product was centrifuged, washed several times with ethanol and water, and dried in a vacuum oven at 52°C for 14 hours to successfully obtain FeS 2- x Se x (x=0.2) Microspheres. FeS produced 2-x Se x The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com