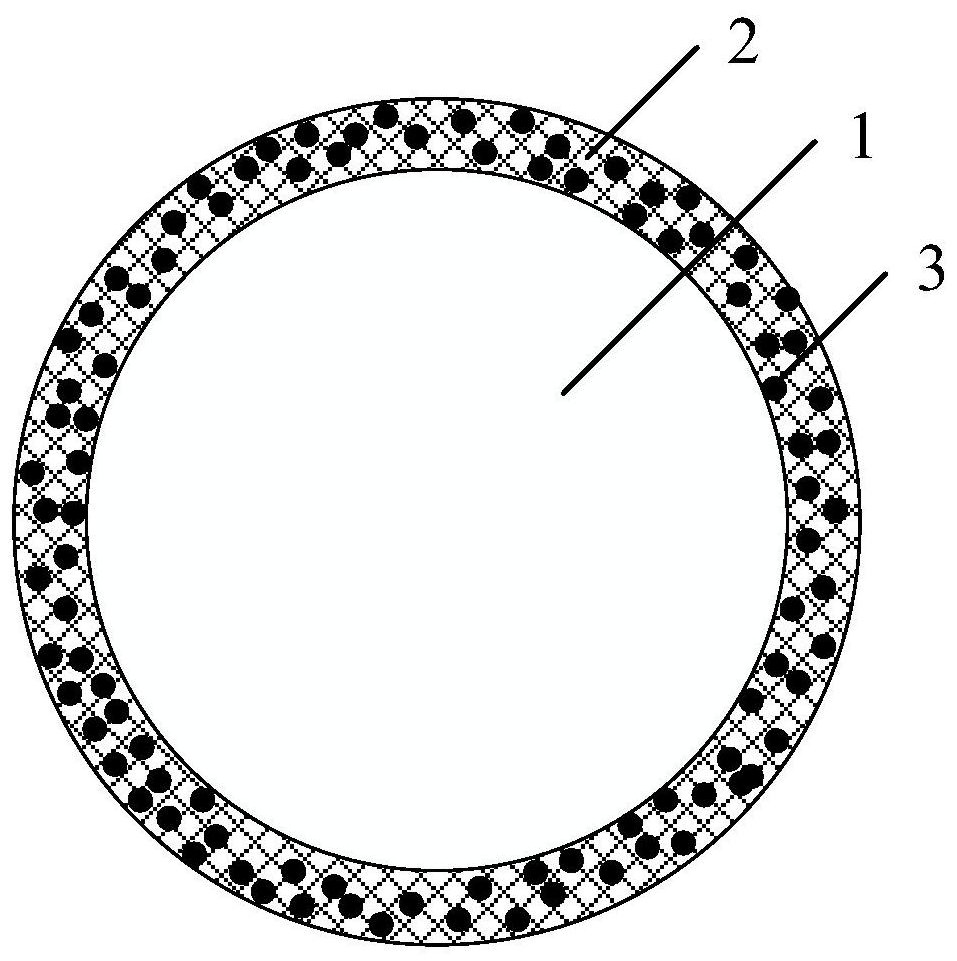

Lead powder with lead oxide-graphene core-shell structure and preparation method thereof

A core-shell structure and graphene technology, applied in structural parts, lead-acid batteries, electrical components, etc., can solve the problems of carbon negative electrodes that are difficult to match and connect, difficult to mix uniformly, and weaken sulfation, etc., to achieve a large increase Current charge and discharge capability, increase the specific surface area, and eliminate the effect of sulfation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

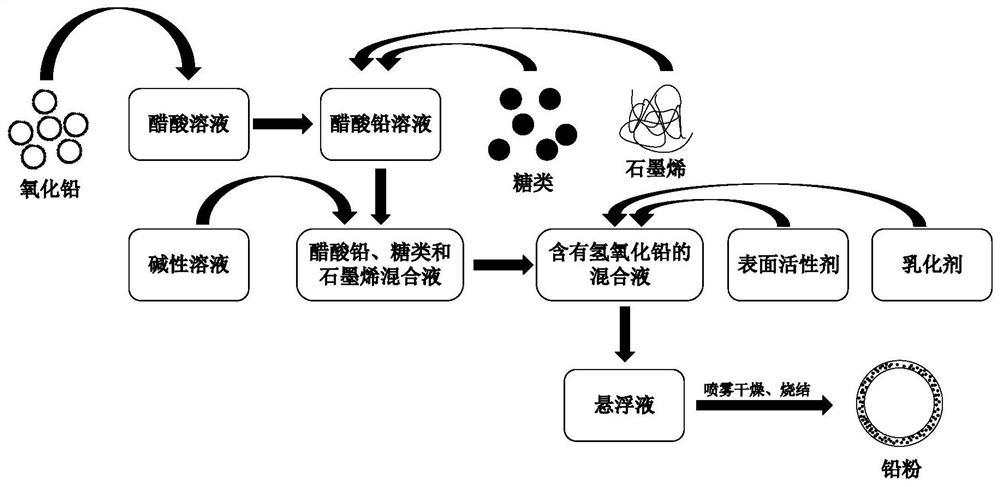

[0048] The present invention also provides a kind of preparation method of the lead powder of lead oxide graphene core-shell structure, see figure 2 , including the following steps:

[0049] Step 1: mixing lead acetate solution, sugars and graphene to obtain a mixed solution of lead acetate, sugars and graphene;

[0050]Step 2: mixing an alkaline solution (for example, ammonia water) with a mixed solution of lead acetate, sugars and graphene, the lead acetate solution will generate lead hydroxide particles when it encounters an alkaline solution, and obtain a mixed solution containing lead hydroxide particles;

[0051] Step 3: mixing the surfactant, the emulsifier and the mixed solution containing the lead hydroxide particles to obtain a suspension;

[0052] Step 4: The suspension is spray-dried sequentially to obtain lead powder precursor particles, wherein the air inlet temperature for spray drying is 160-500°C, and the feed rate for spray-drying is 30-10000ml / h;

[0053]...

Embodiment 1

[0077] The present embodiment provides a lead powder with a lead oxide graphene core-shell structure and a preparation method thereof, comprising the steps of:

[0078] Step A: Add lead oxide into the acetic acid solution to make a lead acetate solution, wherein the mass ratio of lead oxide to acetic acid is 0.7:1;

[0079] Step B: Add glucose and graphene to the lead acetate solution, and stir to make a mixed solution of lead acetate, sugar and graphene, wherein the mass ratio of lead oxide to glucose is 1000:1, and the mass ratio of lead oxide to graphene is 1000 : 0.3;

[0080] Step C: Add ammonia water to the mixed solution of lead acetate, glucose and graphene under continuous stirring conditions to obtain a mixed solution containing lead hydroxide, wherein lead oxide and OH - The molar ratio is 1:2;

[0081] Step D: adding polyvinyl alcohol and carboxymethyl cellulose to the mixed solution containing lead hydroxide particles to obtain a suspension;

[0082] Step E: Th...

Embodiment 2

[0086] The present embodiment provides a lead powder with a lead oxide graphene core-shell structure and a preparation method thereof, comprising the steps of:

[0087] Step A: adding lead oxide into the acetic acid solution to make a lead acetate solution, wherein the mass ratio of lead oxide to acetic acid is 3.2:1;

[0088] Step B: Add fructose, starch and graphene to the lead acetate solution, and stir to make a mixed solution of lead acetate, fructose, starch and graphene, wherein the mass ratio of lead oxide to the total mass of fructose and starch is 1000:2, and the lead oxide and The mass ratio of graphene is 1000:1;

[0089] Step C: Add ammonia water to the mixed solution of lead acetate, fructose, starch and graphene under continuous stirring conditions to obtain a mixed solution containing lead hydroxide, wherein lead oxide and OH - The molar ratio is 1:2.5;

[0090] Step D: adding polyvinylpyrrolidone and water-soluble protein to the mixed solution containing lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com