A kind of preparation method of organosulfur positive electrode material of lithium-sulfur battery

A positive electrode material, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, electrode manufacturing, etc., can solve the problems of increasing operational difficulty and long process routes, and achieve the effect of promoting electrical conductivity and improving high-current charging and discharging capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

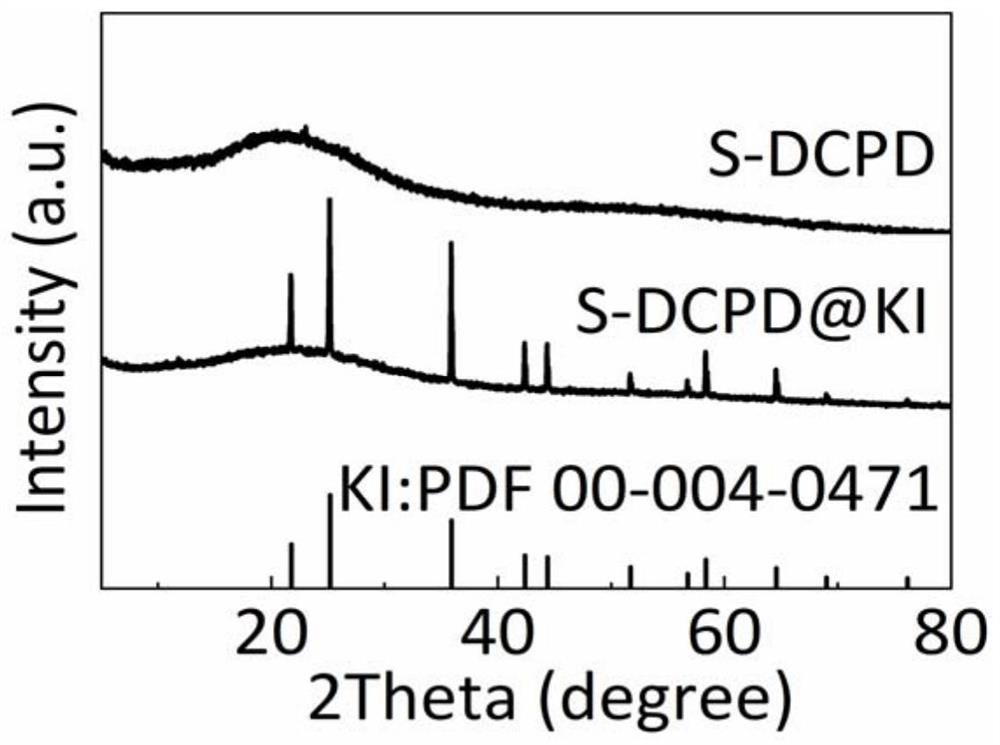

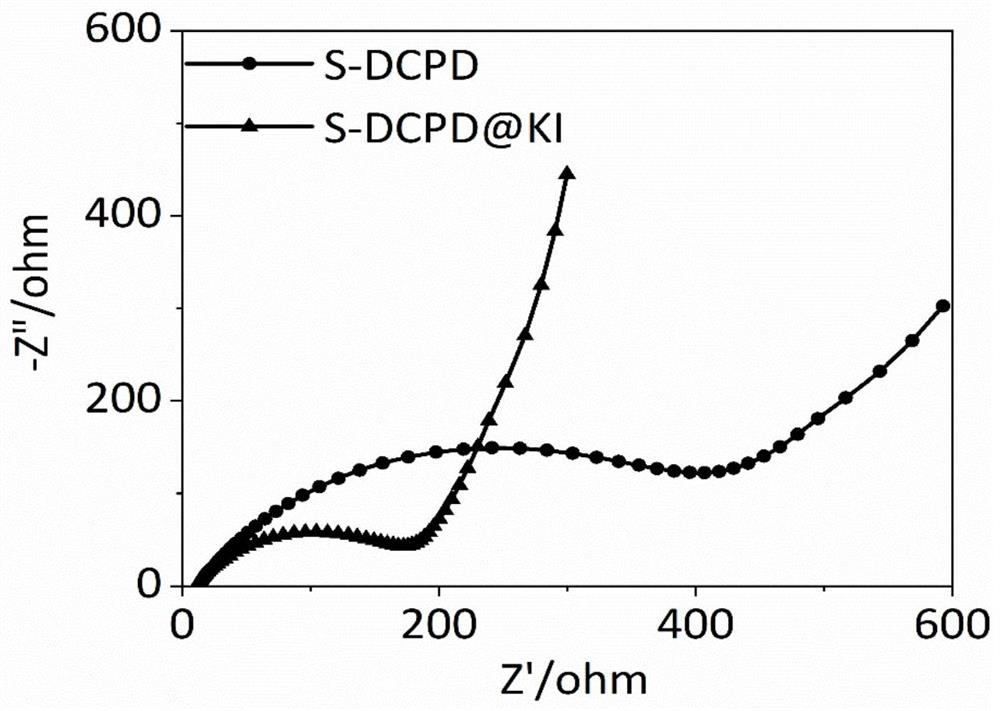

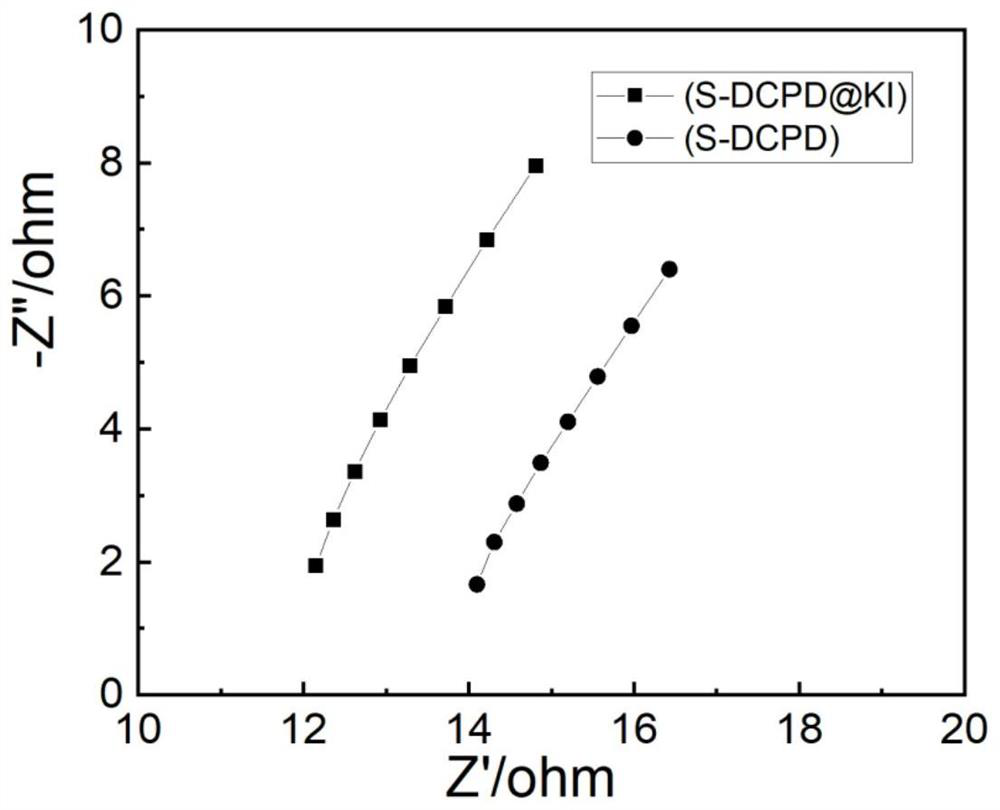

[0037] This example describes the dicyclopentadiene-sulfur@KI cathode material and its preparation method.

[0038] 1) Take dried 6g of sublimed sulfur and 0.5g of KI in a 50ml three-necked flask, and mechanically stir at 185°C for 5.5min under a nitrogen atmosphere to obtain a mixed liquid containing KI;

[0039] 2) Inject 3.5 g of dicyclopentadiene (DCPD) into the product obtained in step 1) at 185°C through a syringe to graft linear sulfur onto the carbon chain of dicyclopentadiene, react for 12 minutes, and obtain a dark red viscous mixture;

[0040] 3) The product obtained in step 2) was quickly quenched in liquid nitrogen, and then placed at 155°C for 4 hours to solidify, and finally the organosulfur cathode material S-DCPD@KI with metallic luster was obtained;

[0041] Weigh 0.08g of organic sulfur cathode material S-DCPD@KI, 0.01g of acetylene black, and 0.01g of polyvinylidene fluoride (PVDF) obtained above, put them in a mortar, mix and grind evenly, then add 1.5ml o...

Embodiment 2

[0048] This example describes the vinyl norbornene-sulfur @NaI cathode material and its preparation method.

[0049] 1) Take dried 6g of sublimed sulfur and 0.5g of NaI in a 50ml three-necked flask, and mechanically stir at 185°C for 5.5min under a nitrogen atmosphere to obtain a mixed liquid containing NaI;

[0050] 2) Inject 3.5 g of vinyl norbornene (VNB) into the product obtained in step 1) through a syringe at 185° C., so that linear sulfur is grafted onto the carbon chain of vinyl norbornene, and react for 20 minutes to obtain a deep red viscous thick mixture;

[0051] 3) The product obtained in step 2) was quickly quenched in liquid nitrogen, and then placed at 155°C for 4 hours to solidify, and finally the organic sulfur cathode material S-VNB@NaI with metallic luster was obtained;

[0052] Lithium-sulfur battery was assembled according to the same method as in Example 1;

[0053] The electrochemical performance test was carried out on the prepared lithium-sulfur bat...

Embodiment 3

[0055] This example describes the styrene-sulfur @AgI cathode material and its preparation method.

[0056] 1) Take dried 6g of sublimed sulfur and 0.5g of AgI in a 50ml three-necked flask, and mechanically stir at 185°C for 5.5min under a nitrogen atmosphere to obtain a mixed liquid containing AgI;

[0057] 2) Inject 3.5 g of styrene (STY) into the product obtained in step 1) at 185° C. through a syringe to graft linear sulfur onto the styrene carbon chain, and react for 11 minutes to obtain a dark red viscous mixture;

[0058] 3) The product obtained in step 2) was quickly quenched in liquid nitrogen, and then placed at 155 ° C for 4 hours to solidify, and finally an organosulfur cathode material S-STY@AgI with black metallic luster was obtained;

[0059] Lithium-sulfur battery was assembled according to the same method as in Example 1;

[0060] The electrochemical performance test was carried out on the prepared lithium-sulfur battery, the voltage window was 1.7V-2.8V, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com