Lead-acid storage battery current collector, manufacturing method, tool and battery

A technology of lead-acid batteries and current collectors, which is applied in the direction of lead-acid batteries, lead-acid battery construction, battery electrodes, etc. It can solve the problems of unsatisfactory mechanical properties, complicated electroplating links, and difficult quality control, and achieve simple and easy manufacturing process Easy to control, reliable quality, more environmentally friendly, time-saving and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

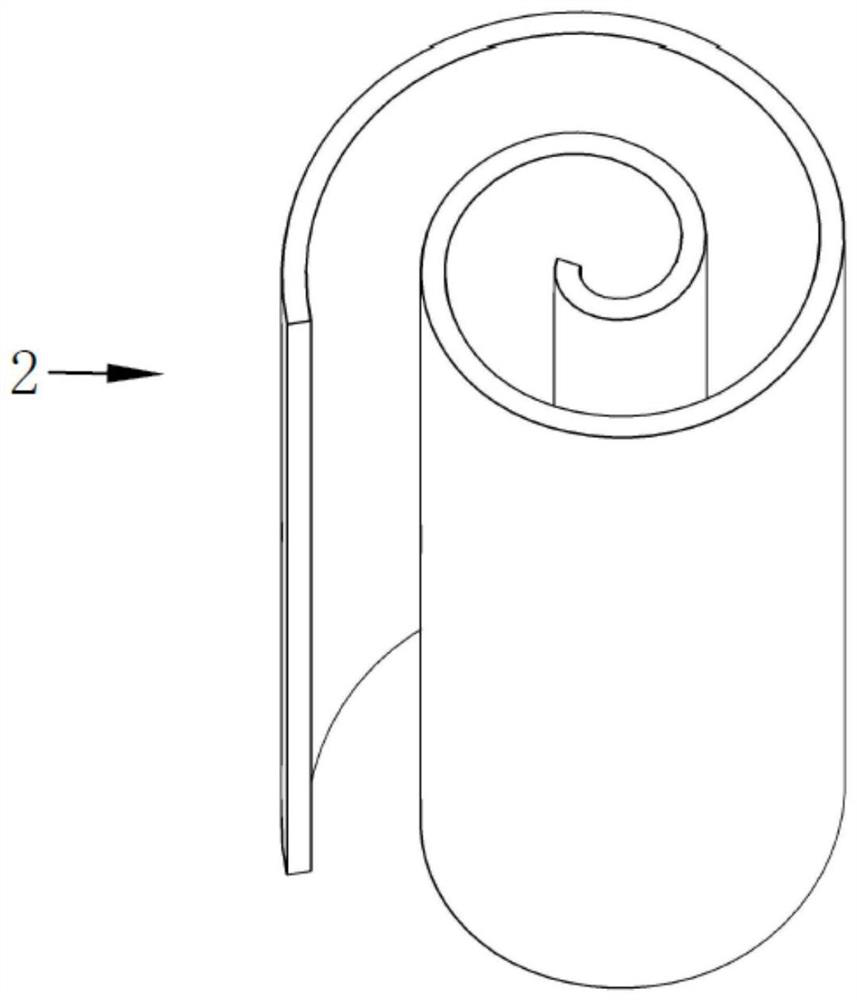

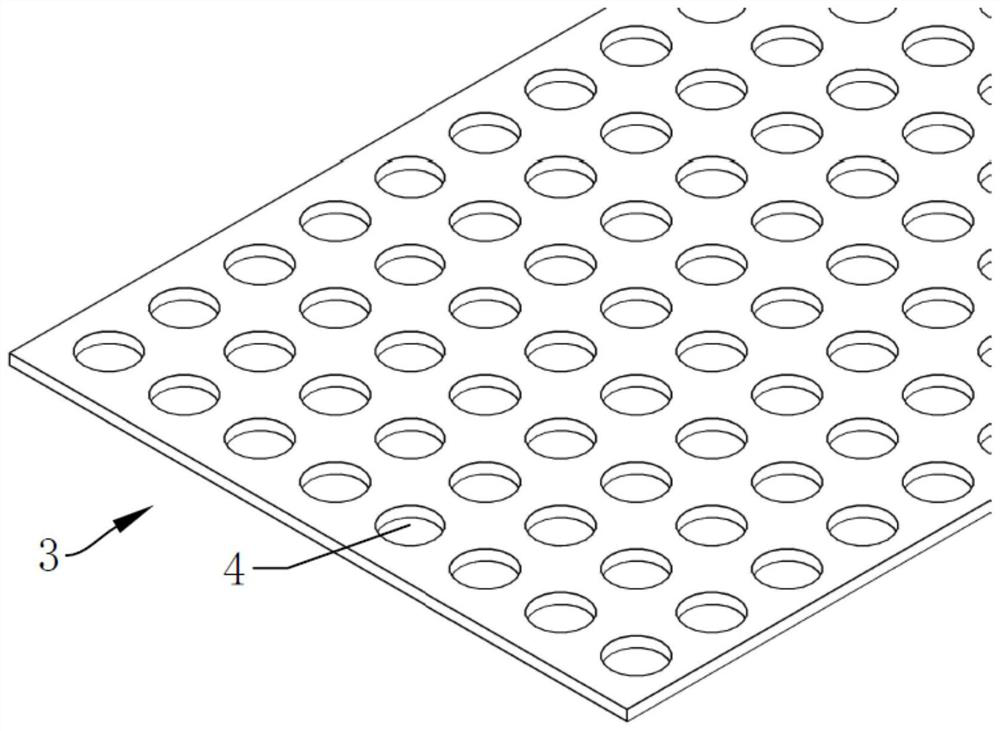

[0136] Such as figure 1 -6. The current collector of the lead-acid battery in this embodiment is one or more of a flat plate 1 , a coiled plate or an arc plate 2 , an orifice plate 3 , a grid or grid 5 , an array 7 , and a comb plate 9 .

[0137] Such as Figure 7 As shown, the lead-acid accumulator current collector plate of the present embodiment includes an upper surface lead skin 12 and a lower surface lead skin 13, a light conductor aluminum 14, an edge-sealing material lead-tin alloy solder 15, and the materials of the lead skins 12 and 13 are all It is metallic lead; the lead skins 12, 13 and the light conductor aluminum 14 are laminated with each other to form a three-layer laminated structure 16, wherein the light conductor aluminum 14 is between the lead skins 12, 13, and is connected with the lead skins 12, 13 Carry out conductive connection; Edge-sealing material lead-tin alloy solder 15 is positioned at the edge of described 3-layer laminated structure 16, throug...

Embodiment 2

[0142] The difference from Example 1 is that, as Figure 8 As shown, the current collector of the lead-acid battery in this embodiment is covered with conductive anti-corrosion layers 17, 18 on the upper and lower surfaces of the light conductor aluminum 14, which are stacked together with the lead skins 12, 13 to form a five-layer stack Structure 19, the light conductor aluminum 14 conducts conductive connection with the lead skin 12 or 13 through the anti-corrosion layers 17, 18, and the edge-sealing material lead-tin alloy solder 15 is located at the edge of the 5-layer laminated structure 19. Through the welding process, the sealing Edge material lead-tin alloy solder 15 is welded together with lead skin 12,13, conductive anti-corrosion layer 17,18, light conductor aluminum 14, and edge sealing material lead-tin alloy solder 15 is welded on lead skin 12,13 Together, a closed space surrounded by the three is formed, and the light conductor aluminum 14 and the conductive ant...

Embodiment 3

[0146] The difference from Example 1 is that, as Figure 9 As shown, the current collector of the lead-acid battery in this embodiment, at the edge of the laminated structure 16, the edge-sealing material lead-tin alloy solder 15 is welded and combined with the edges of the lead skins 12 and 13 in the space between the lead skins 12 and 13 Together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com