Logistics system

A technology of logistics system and feeding system, applied in the field of logistics system, can solve problems such as collision of active rollers and damage of materials to be processed, and achieve the effect of preventing collision damage and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

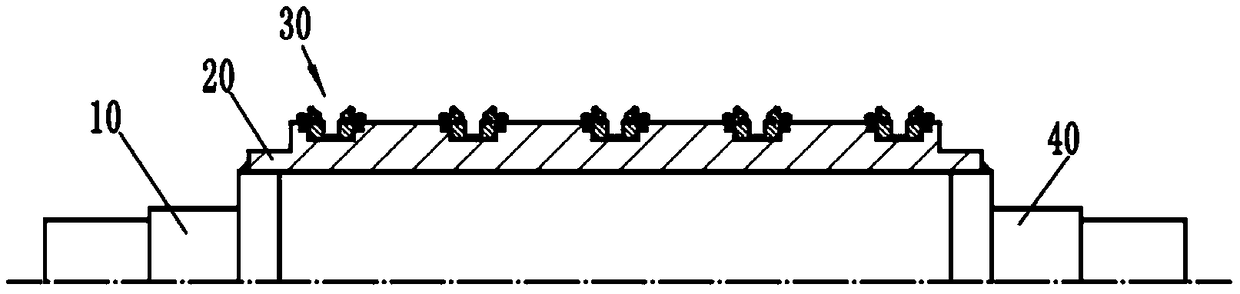

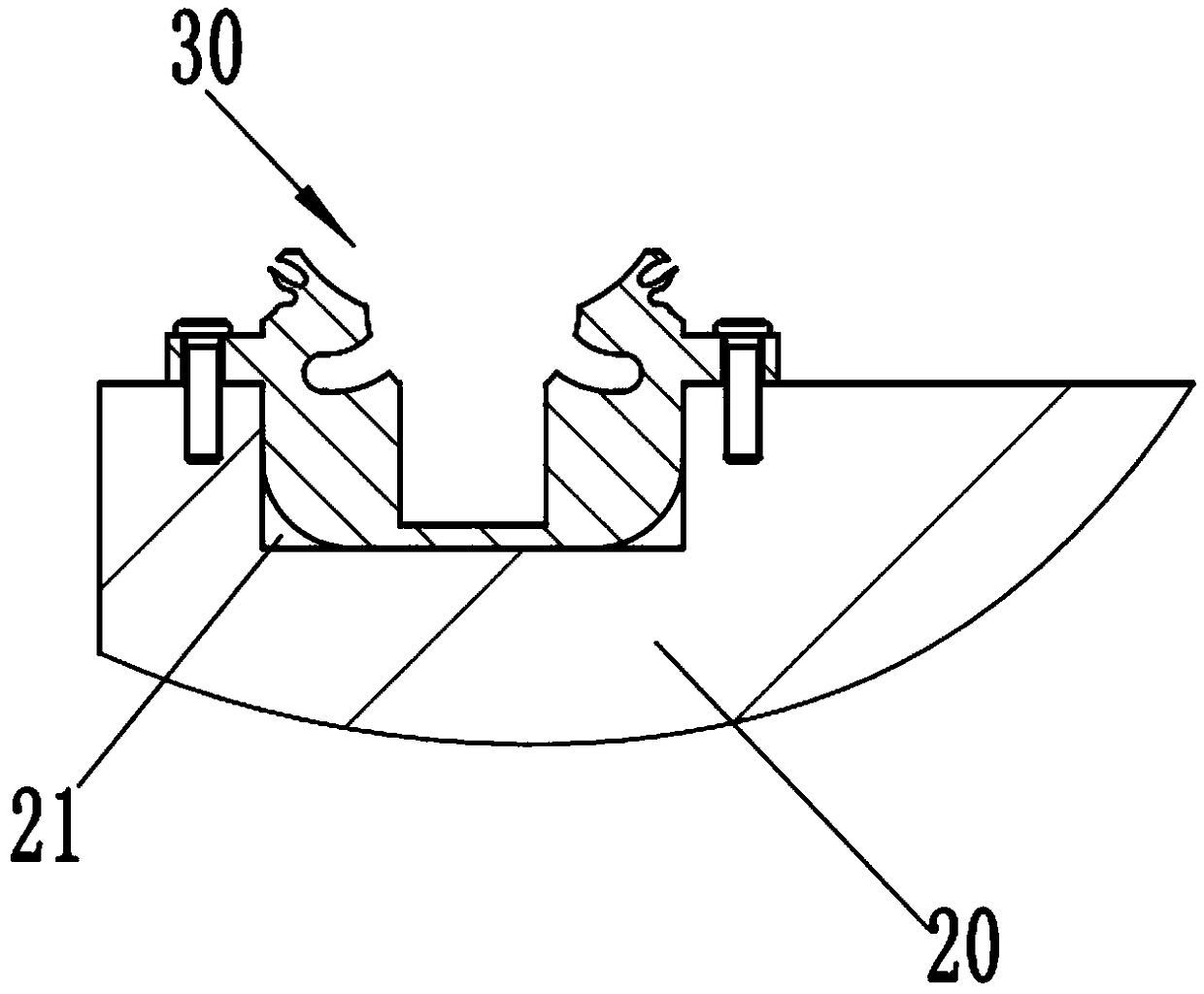

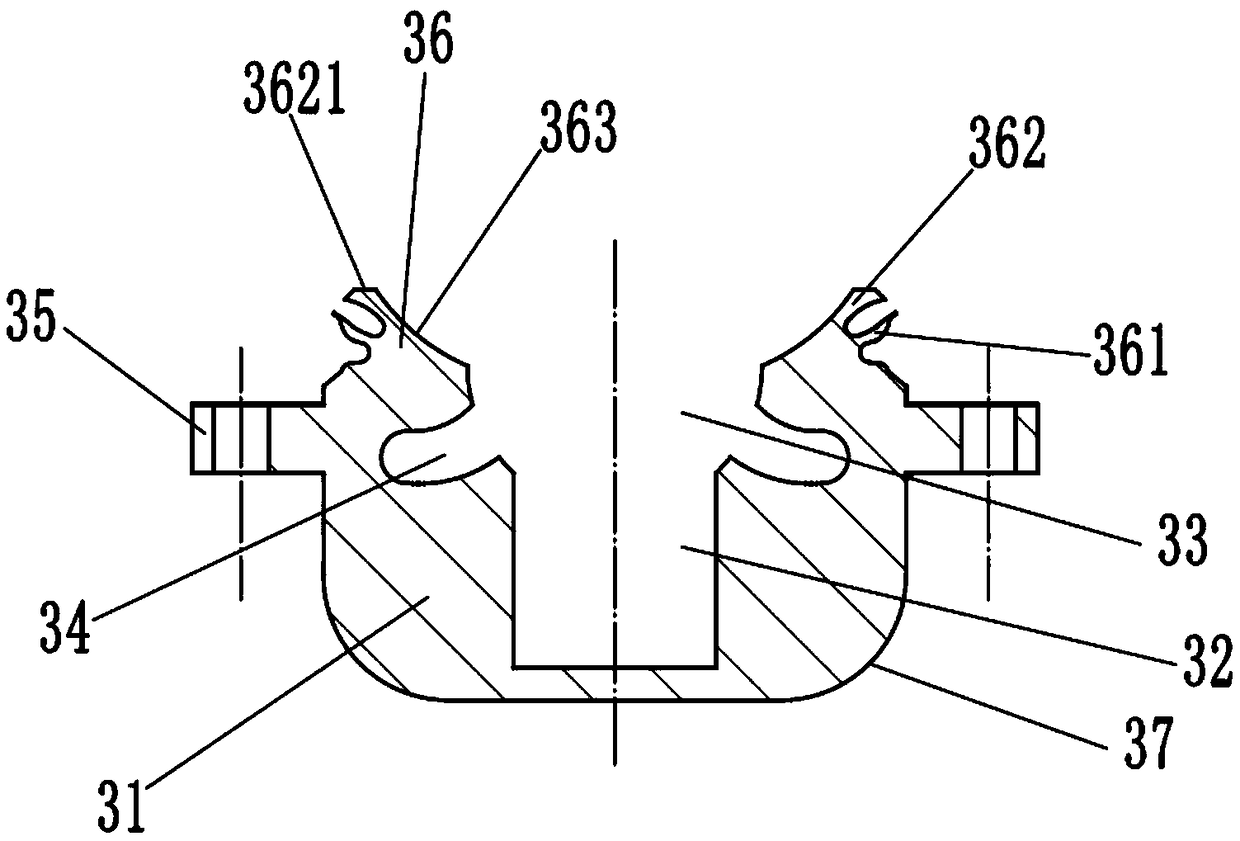

[0026] Refer below Figure 1 to Figure 5 The present invention is further described, as figure 1 A logistics system shown includes a feeding system, a feeding elevator, a workbench, a discharging elevator and a discharging system. The feeding system includes a feeding conveying line, and the feeding conveying line includes several feeding driving rollers. The material driving roller includes: a cylinder body 20, a left end shaft 10, a right end shaft 40 and several elastic rings 30, the cylinder body 20 is provided with several annular grooves 21, and the left end shaft 10 is connected to the left end of the cylinder body 20, the right end The shaft 40 is connected to the right end of the cylinder body 20, and several elastic rings 30 are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com