Self-balancing device and self-balancing method for steel wire tension

A steel wire rope and self-balancing technology, applied in the field of steel wire rope tension self-balancing device and its self-balancing, can solve the problems of poor working reliability, complicated mechanism setting, leakage judgment, etc., and achieve uniform force, simple mechanism setting and improved service life. Effect

Inactive Publication Date: 2019-11-01

CHINA UNIV OF MINING & TECH

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, the tension adjustment of hoisting wire ropes usually uses tension measuring devices to measure the tension of each hoisting wire rope multiple times to determine the force of each hoisting wire rope, and then adjust the rope head of the corresponding hoisting wire rope through a telescopic control mechanism such as a balance hydraulic cylinder. Adjustment is performed to balance the tension of the wire rope. This traditional adjustment method usually requires a hydraulic system or an electric control system. The mechanism setting is relatively complicated, and the work reliability is relatively poor. It is easy to cause misjudgment or failure due to factors such as dust coverage or leakage.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0027] As an embodiment of the rack drive of the present invention, the rack and the pinion are a spur meshing structure.

[0028] As another embodiment of the rack drive of the present invention, the rack and the pinion are in a helical meshing structure. The meshing structure of helical teeth can achieve better meshing performance due to the large degree of overlap, so that the structure can be more compact.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

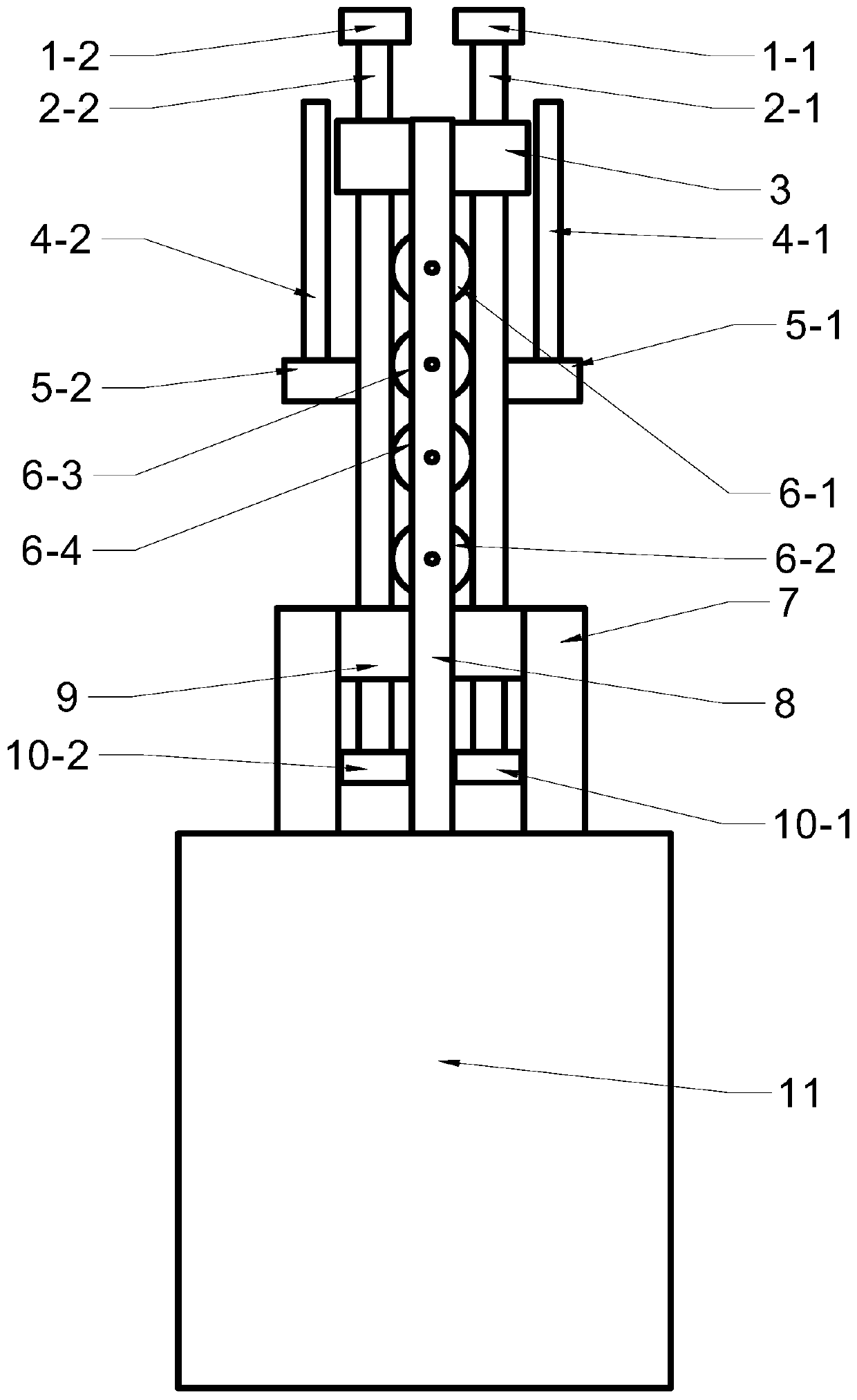

The invention discloses a steel wire rope tension self-balancing device and a self-balancing method thereof. The steel wire rope tension self-balancing device is of an eudipleural structure and comprises an upper limiting switch, a rack, an upper positioning and guiding support beam, a steel wire rope connector, a gear, a lower bracket, an upright column, a lower positioning and guiding support beam and a lower limiting switch. According to the steel wire rope tension self-balancing device, when a lifting container ascends or descends to stop positions, in the process that personnel enter andexit or goods enter and exit, a lifting steel wire rope on the small-tension side can be controlled to lift by an electric control device of a steel wire rope lifting and conveying system according tothe feedback of the upper limiting switch on the top end of the rack or the lower limiting switch on the bottom end of the rack, and the rack on the large-tension side is driven to move downwards through the driving of a gear rack so as to balance the tension. The steel wire rope tension self-balancing device has the advantages of the simple structure and reliability in movement and is especiallysuitable for the lifting and conveying system for lifting and conveying through the steel wire rope, the tension of each lifting steel wire rope can be automatically adjusted, and the stress is uniform.

Description

technical field [0001] The invention relates to a steel wire rope tension self-balancing device and its self-balancing method, in particular to a steel wire rope tension self-balancing device and its self-balancing method suitable for hoisting transportation systems such as mine hoisting and traction elevator hoisting, which are lifted and transported by steel wire ropes The method belongs to the technical field of steel wire rope hoisting transportation. Background technique [0002] Mine hoisting, traction elevator hoisting and other hoisting transportation systems that use changing potential energy for transportation, in which wire ropes are wound on hoisting drums and hoisting by driving wire rope drums is the most widely used, usually divided into single-container hoisting systems (hoisting wire ropes) One end is connected to a lifting container such as a cage or a car, and the other end is connected to a balance weight) and a multi-container lifting system (both ends o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B66B7/10

CPCB66B7/10

Inventor 张宁曹国华朱真才彭维红花纯利周公博彭玉兴李伟汤裕刘善增

Owner CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com