Coaxial 190-degree evagination rotating mechanism applied to flexible screen

A technology of a rotating mechanism and a flexible screen, applied in the directions of shafts, pivots, shafts and bearings, can solve the problem that traditional rotating shafts cannot meet functional requirements, and achieve the effect of meeting high-precision control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

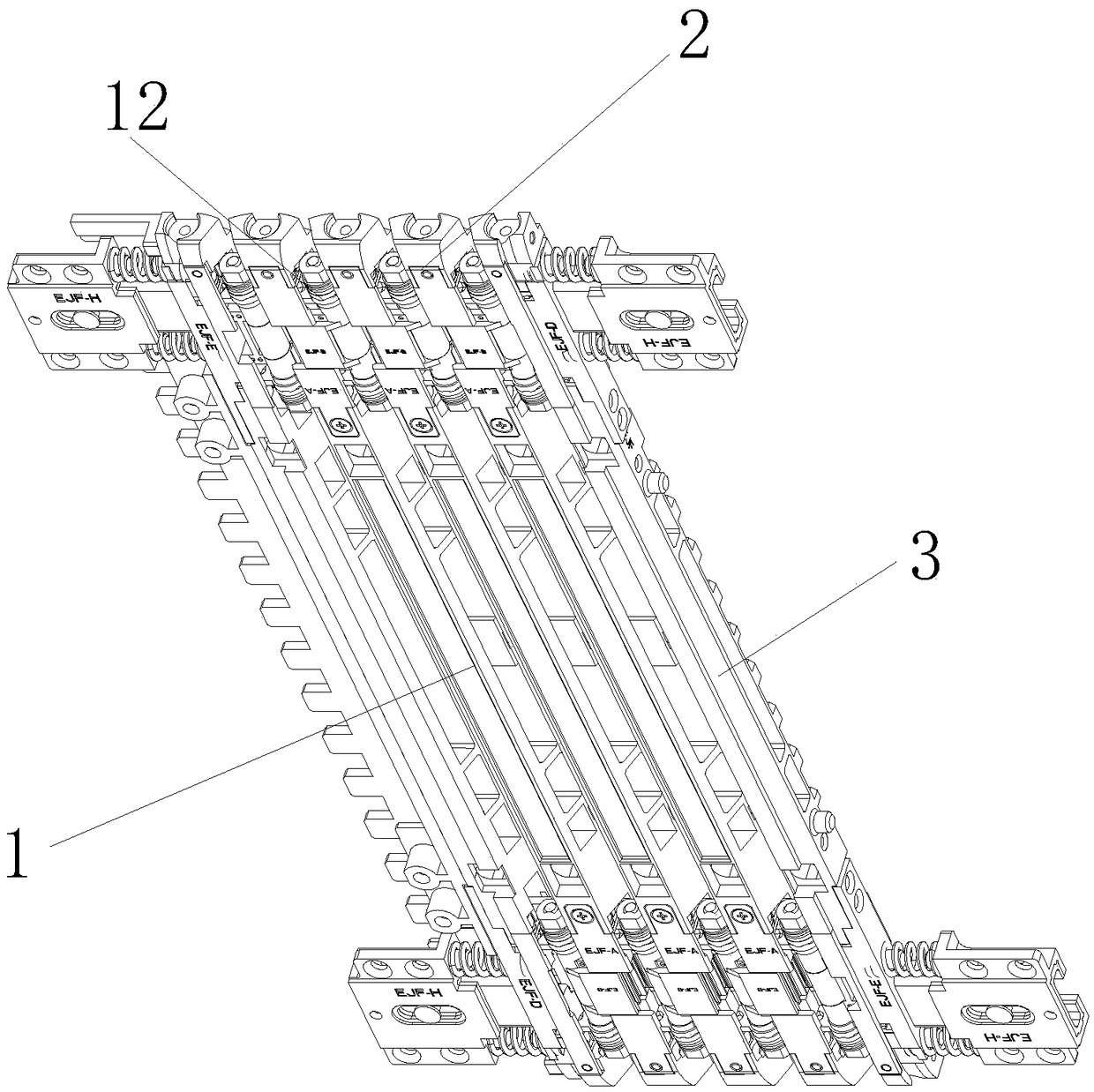

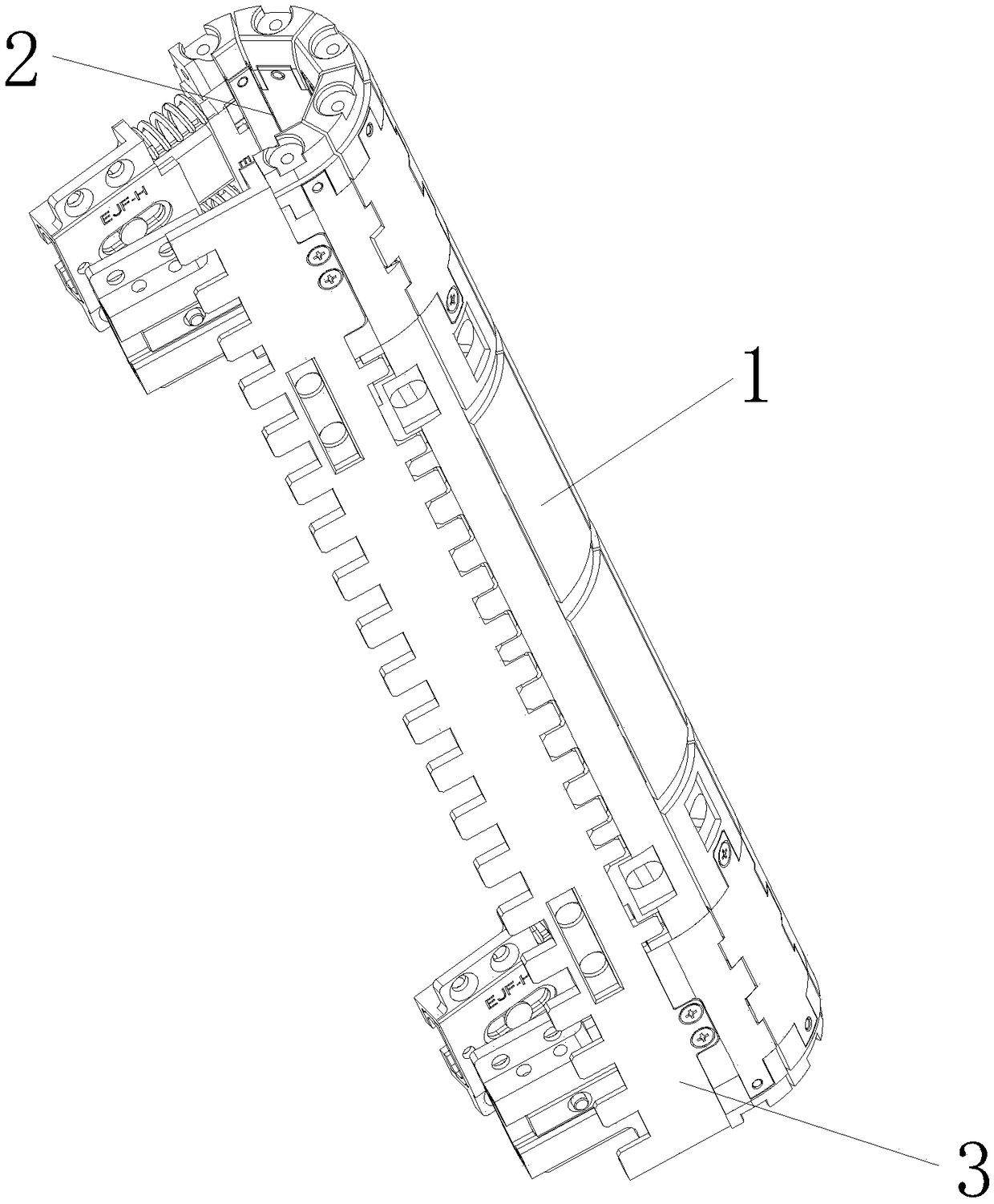

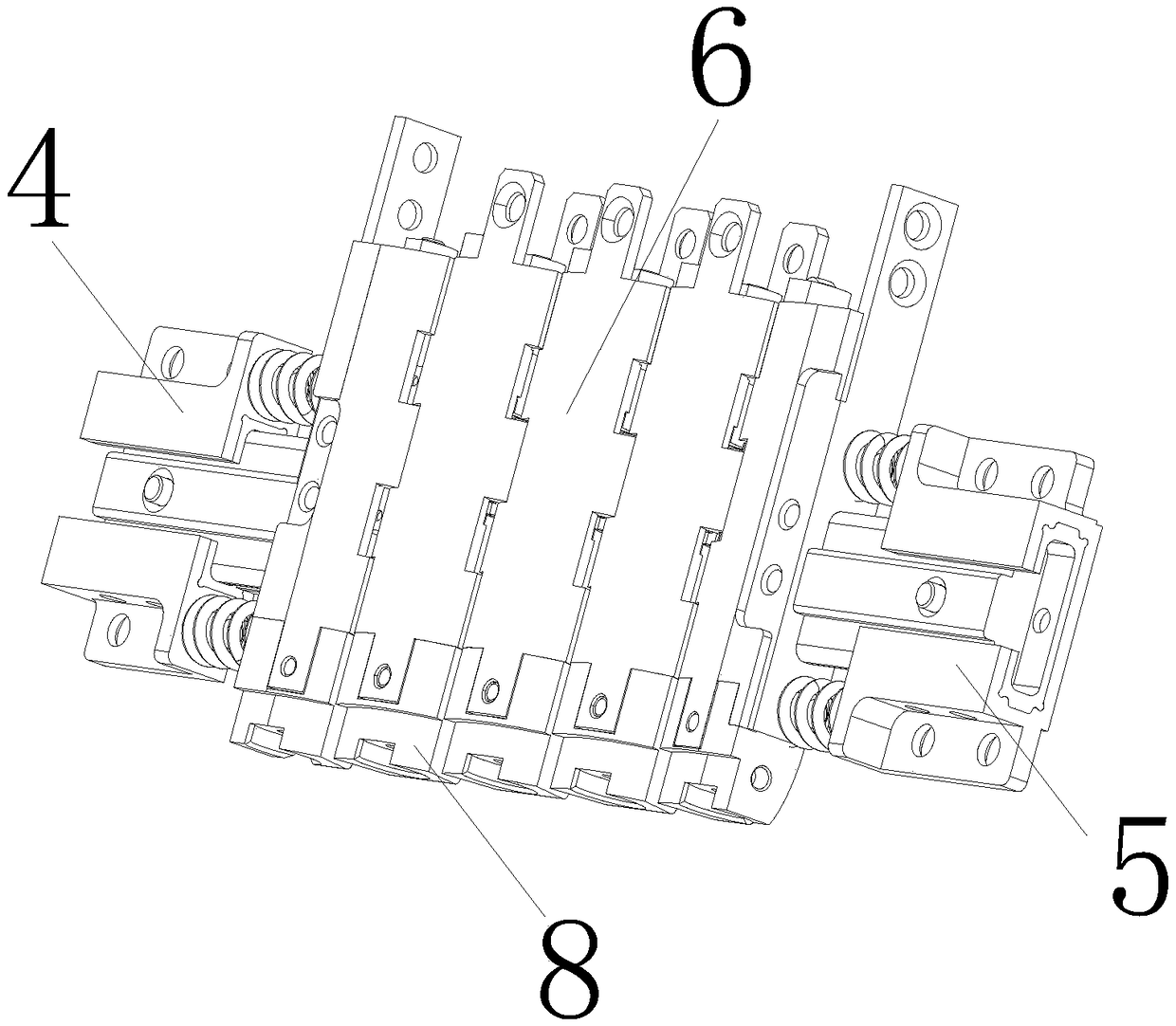

[0021] Such as Figure 1-5 As shown, this embodiment discloses a coaxial 190-degree outward folding rotation mechanism for flexible screen applications, including a structural main body 1, and the structural main body 1 is composed of outer folding shafts 2 on both sides and arranged between The outer turning shaft 2 includes a left slide rail spring mechanism 4 at both ends, a right slide rail spring mechanism 5 and a rotating mechanism 6 connected by rotation in the middle. The long side of the rotating mechanism 6 Damping mechanisms 7 are respectively provided on both sides, and a side packaging body 8 is provided on the outside of one of the damping mechanisms 7; the rotating mechanism 6 includes a first connecting block 9, a second connecting block 10 and a third The connecting block 11, the first connecting block 9, the second connecting block 10 and the third connecting block 11 are respectively provided with connecting and fixing blocks 12, and the connecting and fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com