A device and method for detecting straightness of deep and long holes

A detection device and straightness technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high price, affecting measurement accuracy, complicated operation, etc., and achieve high automation, high measurement accuracy and low measurement cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

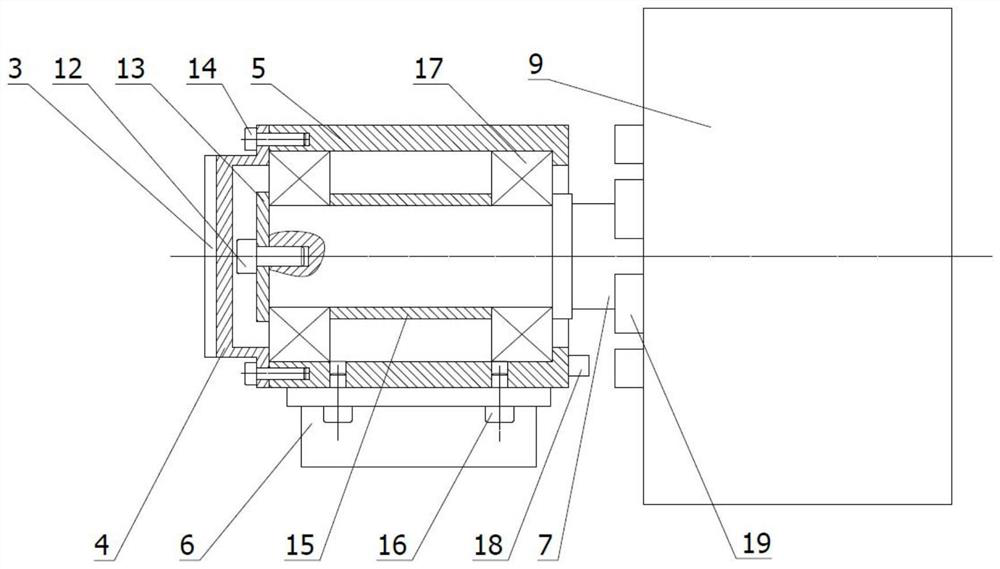

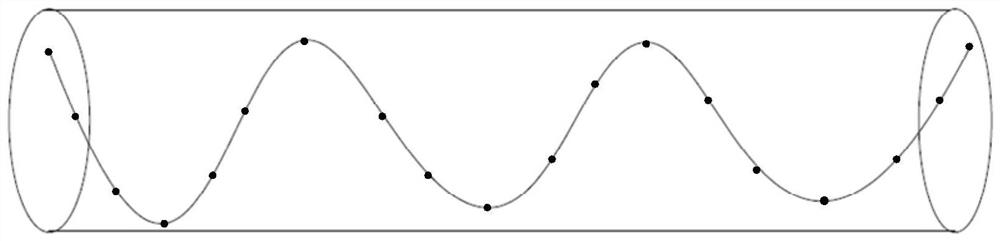

[0030] The specific implementation method is as follows: turn on the power supply, and the self-centering walking mechanism 9 starts to drive the mirror fixing device 5 to move along the axis in the deep hole. The toggle fixing device 5 swings around the central installation axis 7, and when the reading of the inclinometer 6 is 0, the reading of the photoelectric autocollimator 1 is recorded and saved. When the self-centering walking mechanism 9 moves to a certain position, the power is turned off, and the measurement ends. Finally, the computer processes the obtained data and fits a space curve to calculate the error.

[0031] The present invention also relates to a method for measuring straightness of deep and long holes, such as Figure 5 As shown, using the above-mentioned deep and long hole straightness measuring device includes the following steps:

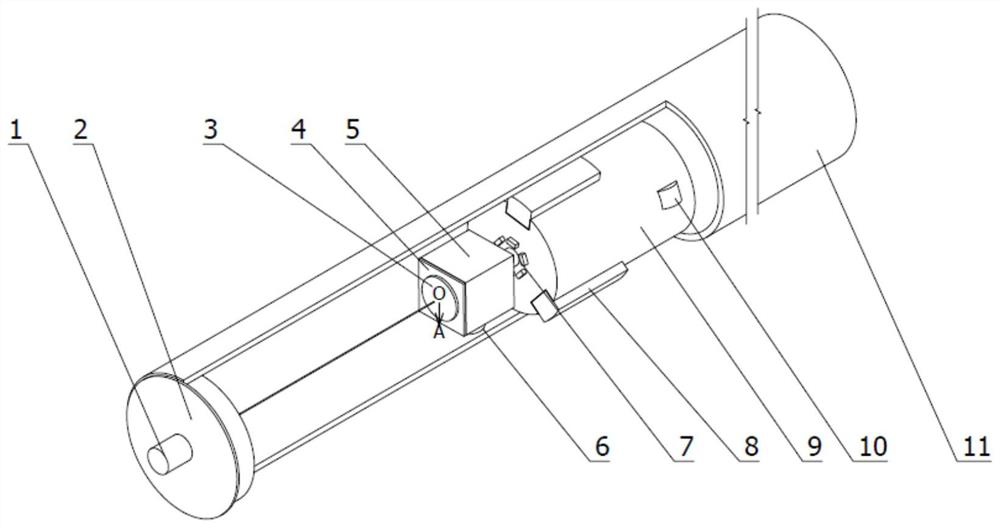

[0032] (1) Put the measuring mechanism and the self-centering walking mechanism 9 into the deep hole parts 11 in sequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com