Impact excitation system and test system based on impact excitation system

A technology of impact excitation and testing system, which is applied in the direction of impact testing, machine/structural component testing, measuring devices, etc. It can solve the problems of secondary impact and inability to accurately obtain impulse response, so as to avoid secondary impact and remove noise , the effect of accurate experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will now be further described in conjunction with the embodiments and accompanying drawings:

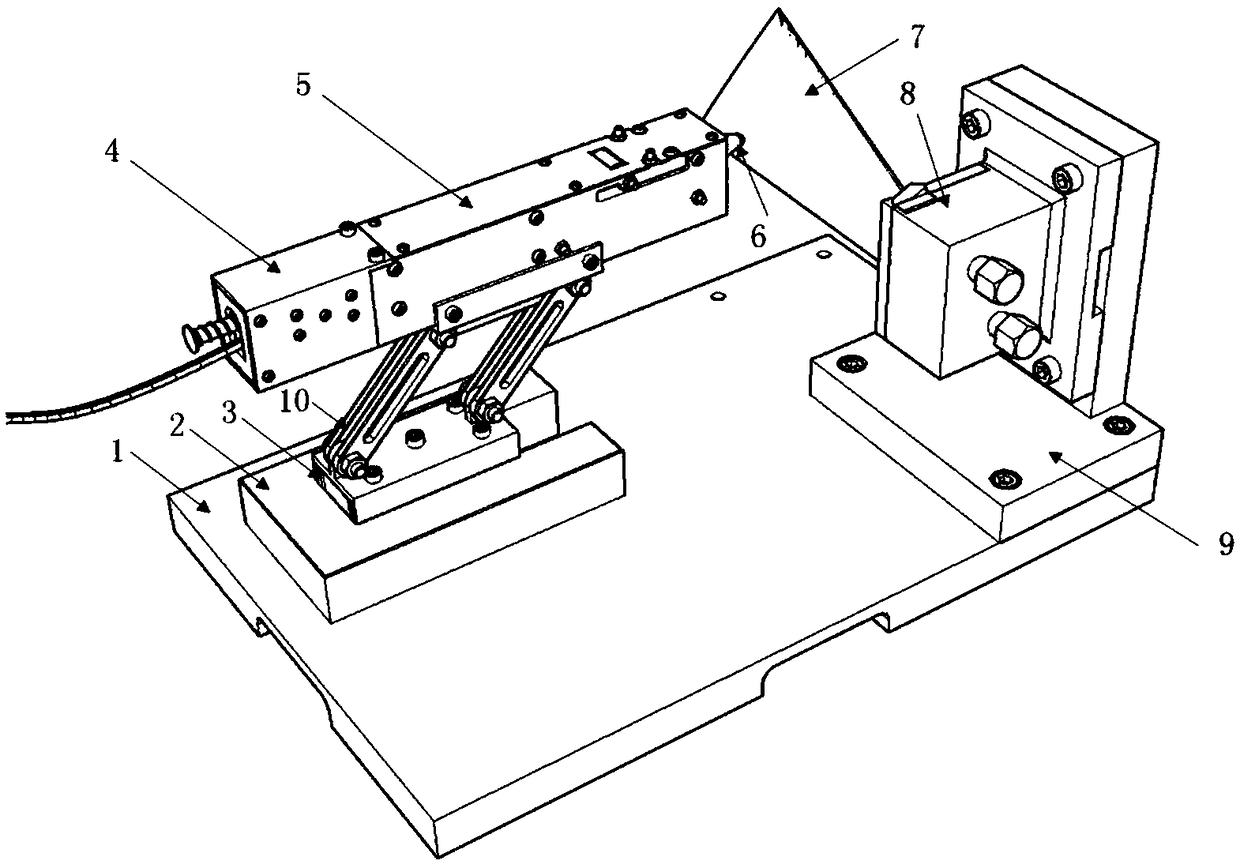

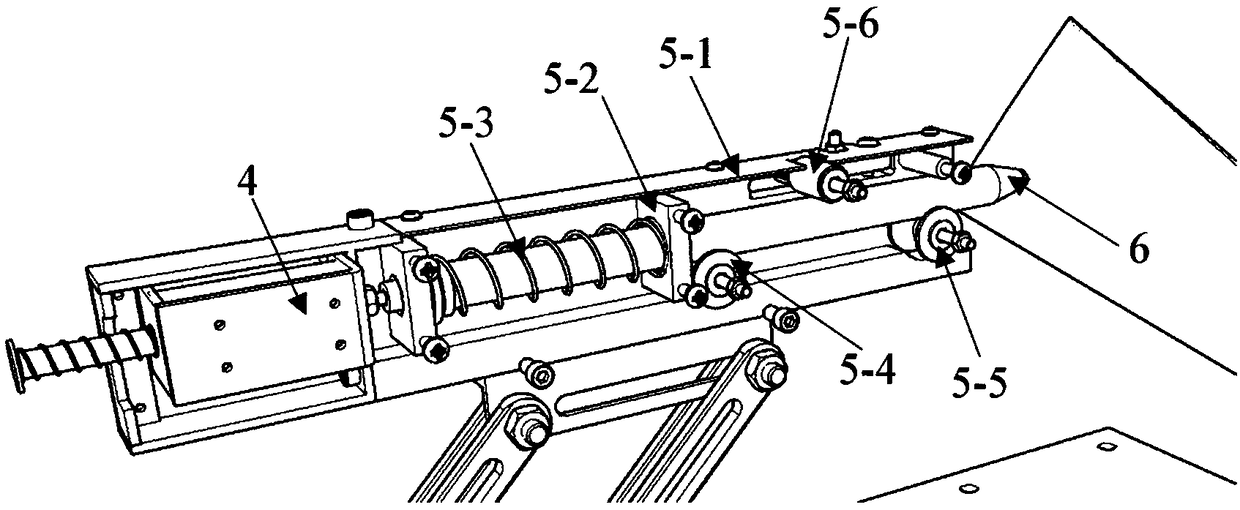

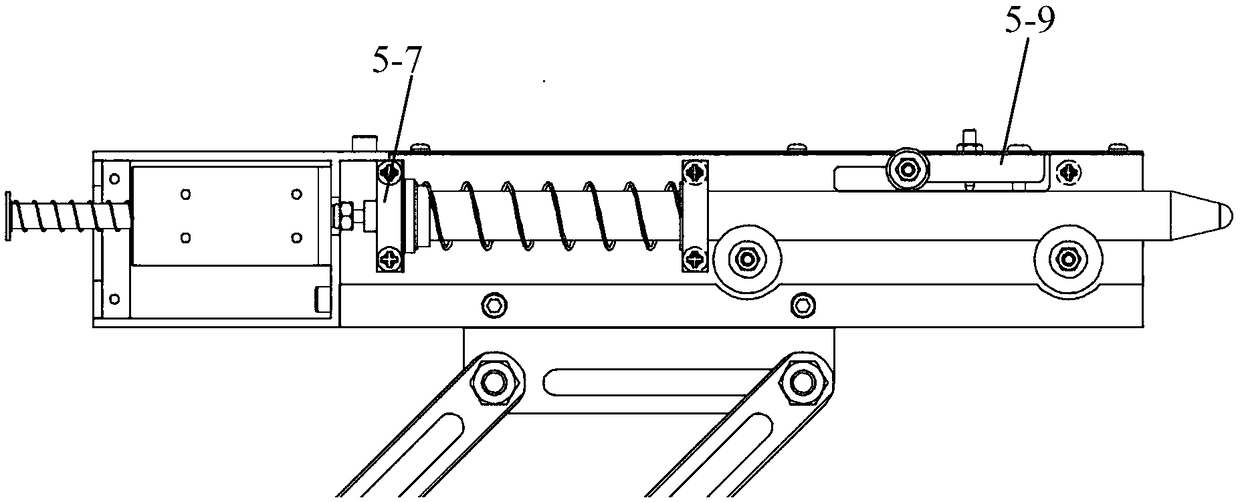

[0025] The embodiment includes a fixed base 1, a magnetic square box auxiliary support block 2, a magnetic square box 3, an electromagnet 4, an impact box 5, an impact box shell 5-1, a rebound spring baffle 5-2, and a rebound spring 5-3 , Front V-shaped limit roller 5-4, rear V-shaped limit roller 5-5, cylindrical limit roller 5-6, baffle 5-7, top screw 5-8, impact rod 6, measured blade 7, Vibration measurement system 8 , vibration measurement system support block 9 and position adjustment bracket 10 .

[0026] One end of the impact box 5 is provided with an electromagnet 4, and the contact of the electromagnet 4 is placed in the through hole in the center of the baffle plate 5-7; the impact rod 6 passes through the rebound spring baffle plate 5-2 and the rebound spring 5-3 and The punch 4-1 of the electromagnet 4 is in contact but not connected, the baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com