Empirical Mode decomposition (EMD)- and Aproximate entropy (ApEn)-based acoustic emission signal characteristic extraction method of rolling bearing

An acoustic emission signal, rolling bearing technology, applied in mechanical bearing testing, pattern recognition in signals, character and pattern recognition, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

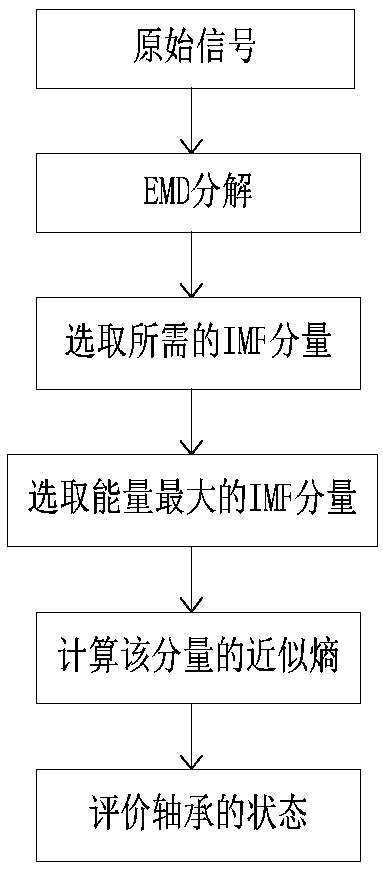

[0052] Such as figure 1 As shown, a kind of rolling bearing acoustic emission signal feature extraction method based on EMD and approximate entropy provided by the present invention, the method comprises the following steps:

[0053] (1) Perform empirical mode decomposition on the acoustic emission signal of the rolling bearing fault to obtain n IMF components and a residual component. This operation includes the following steps:

[0054] (1.1) Determine all local maximum and minimum points in the acoustic emission signal X(t), and use cubic spline curves to connect all local maximum points and local minimum points to form an upper envelope and a lower envelope network;

[0055] (1.2) Calculate the mean value of the upper and lower envelopes, denoted as m 1 , put m 1 Separated from the original signal X(t), we get:

[0056] h 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com