Quasi-static anti-seismic test loading device with capacity of vertical uniform loading

A technology of uniform loading and seismic test, which is applied in the direction of applying stable tension/pressure to test the strength of materials and the generation of seismic energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

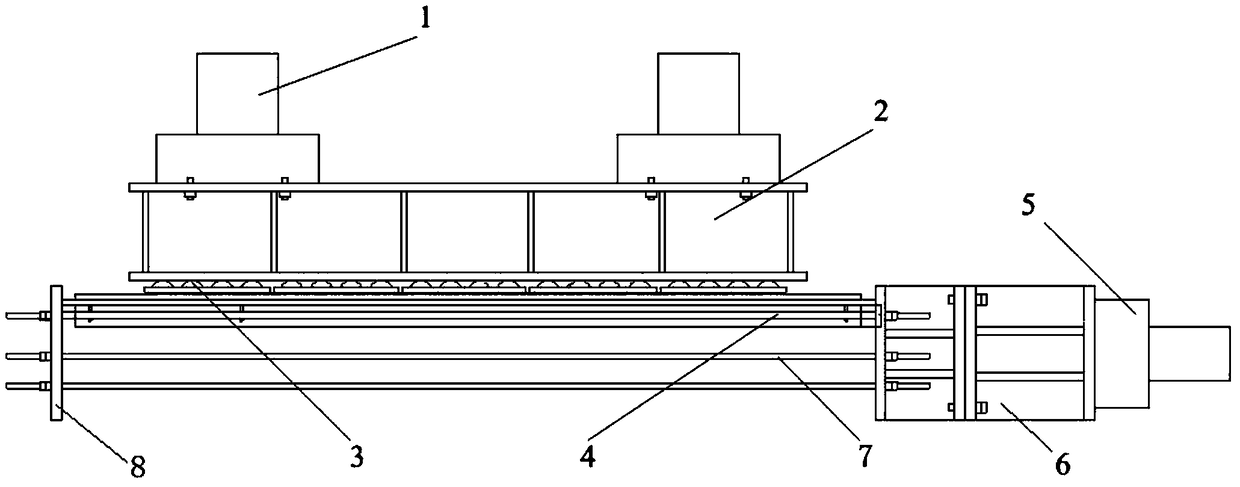

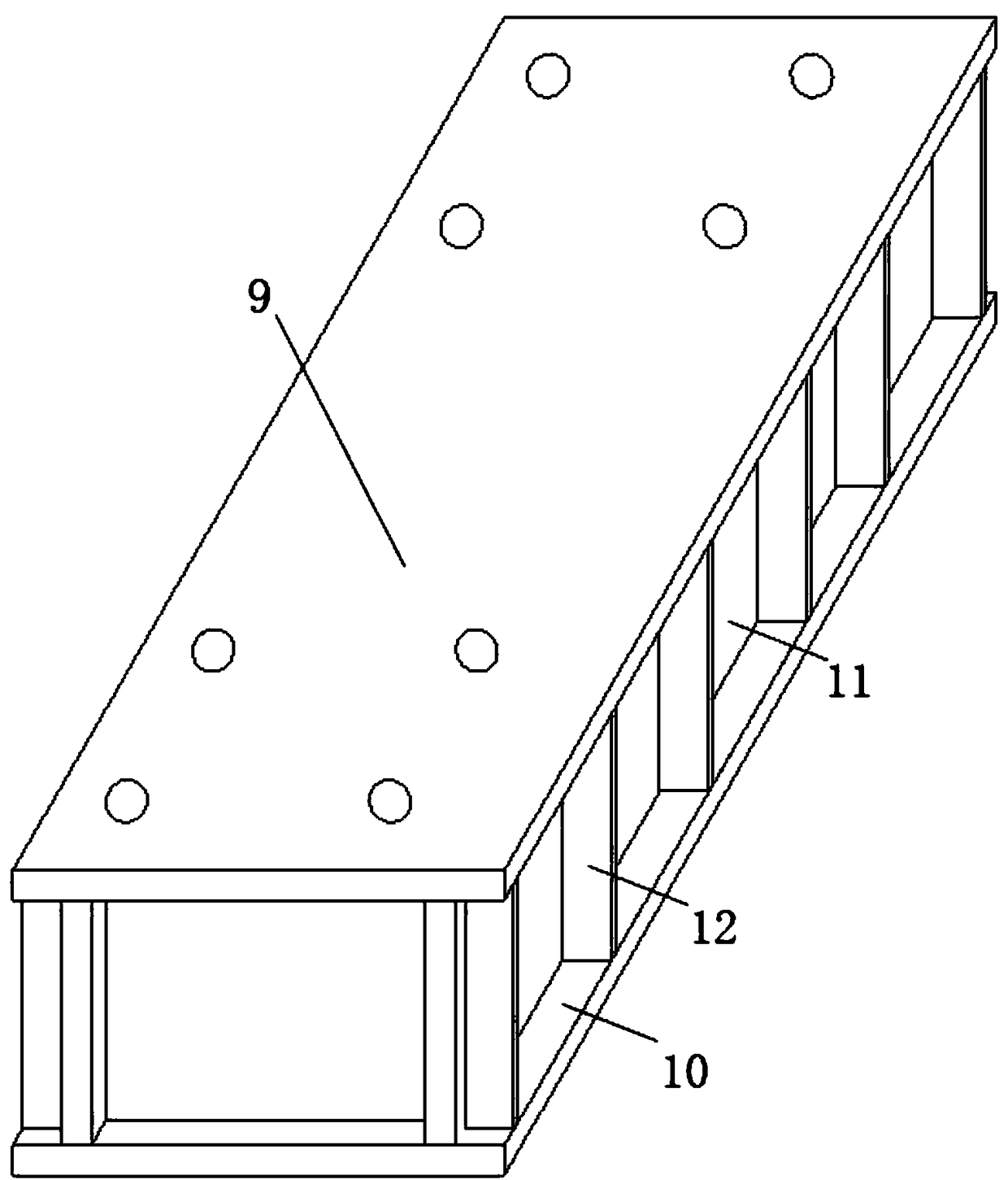

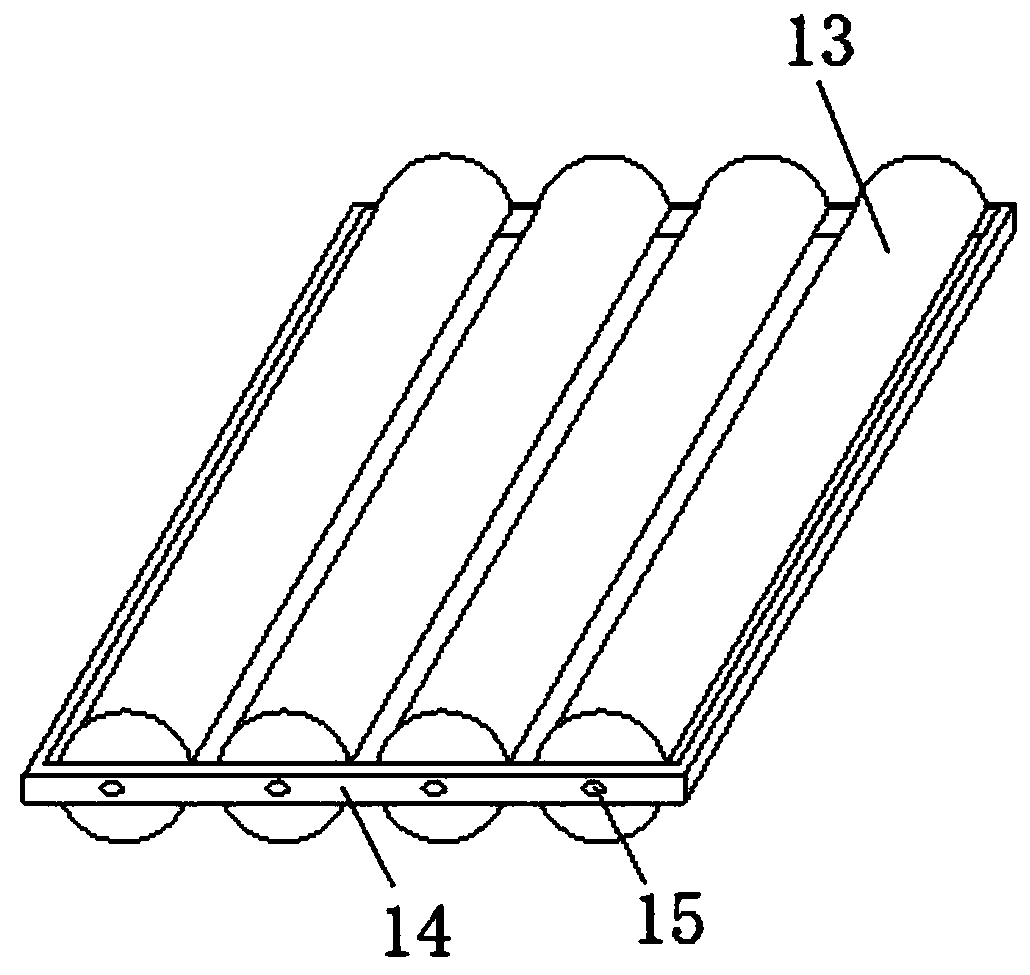

[0023] like Figure 1 to Figure 5 As shown, a pseudo-static seismic test loading device with uniform vertical loading includes a vertical actuator 1, a distribution beam 2 connected to the vertical actuator 1, a horizontal transverse actuator 5, and a horizontal transverse actuator 5. The connecting beam 6 connected to the actuator 5, the loading beam fixing plate 8, several screw rods 7 passing through the connecting beam 6 and the loading beam fixing plate 8 at the same time, the rolling bar track beam 4 fixed on the upper part of the connecting beam 6 at one end, several groups The rolling rod assembly 3 includes a fixed frame 14 and several rolling rods 13 installed in the fixed frame 14 that roll in the same direction and have constant spacing. Both sides of the top surface of the rolling rod track beam 4 are provided with steel rails 16 and Limit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com