Microstructure Texture Characterization Method Based on Gray Scale Processing

A technology of microstructure texture and grayscale processing, applied in the field of image processing, can solve the problems of human eye damage, insufficient clarity of image products, high light brightness, etc., and achieve the effect of clear patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

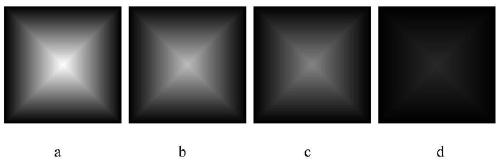

[0040] Combine Figure 1 to Figure 3 A detailed description will be given of a method for depicting a microstructure texture based on grayscale processing in this embodiment.

[0041] According to the needs of the fineness of the image, the resolution of the image is generally selected as 500-1000dpi. In this embodiment, 508dpi is selected, that is, there are 508 pixels per inch. In this embodiment, the microstructure is selected as a regular quadrangular pyramid, the side length of the bottom of the regular quadrangular pyramid is the size of each pixel, and the size of the pixel is 25400um / 508=50um.

[0042] Determine the size of the vertex angle of the regular quadrangular pyramid: make a series of 30mm*30mm test boards in sequence, and each test board is arranged in a full plate with a size of 50um quadrangular pyramids on the bottom side. The depth of the regular quadrangular pyramids takes different values from large to small. The depths of the square pyramids provided on...

Embodiment 2

[0046] Combine figure 1 with figure 2 A detailed description will be given of a method for depicting a microstructure texture based on grayscale processing in this embodiment.

[0047] According to the needs of the fineness of the image, the resolution of the image is generally selected as 500-1000dpi. In this embodiment, 1000dpi is selected, that is, there are 1000 pixels per inch. In this embodiment, the microstructure is selected as a cone, the diameter of the bottom of the cone is the size of each pixel, and the size of the pixel is 25400um / 1000=25.4um.

[0048] The determination of the vertex angle of the regular quadrangular pyramid: a series of 30mm*30mm test boards are made in sequence, and each test board is fully arranged with cones with a bottom diameter of 25.4um. The depth of the cones varies from large to small, and each test The depths of the cones provided on the plate are the same. And determine the brightness range that passes the test board, that is, the maxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com