A cooling device for a downhole submersible motor

A cooling device, oil motor technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problem of inability to cool down the surface of the motor, and achieve the effects of improving service life, reducing production costs and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

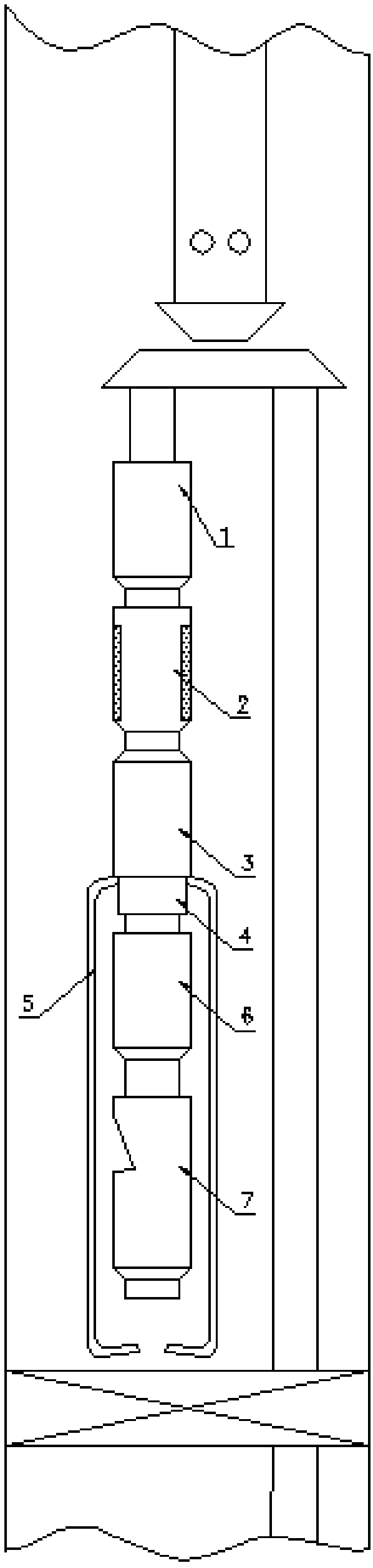

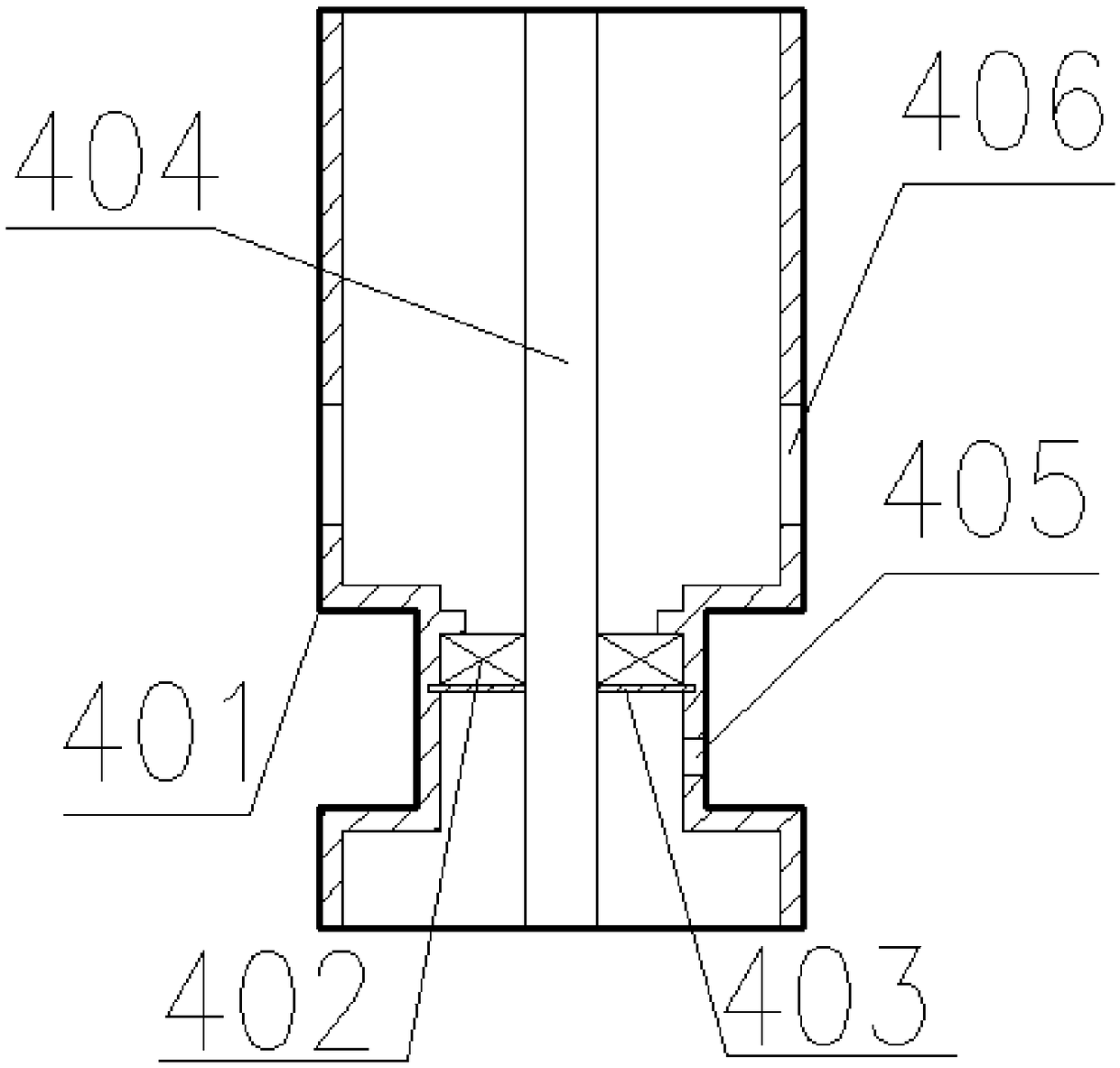

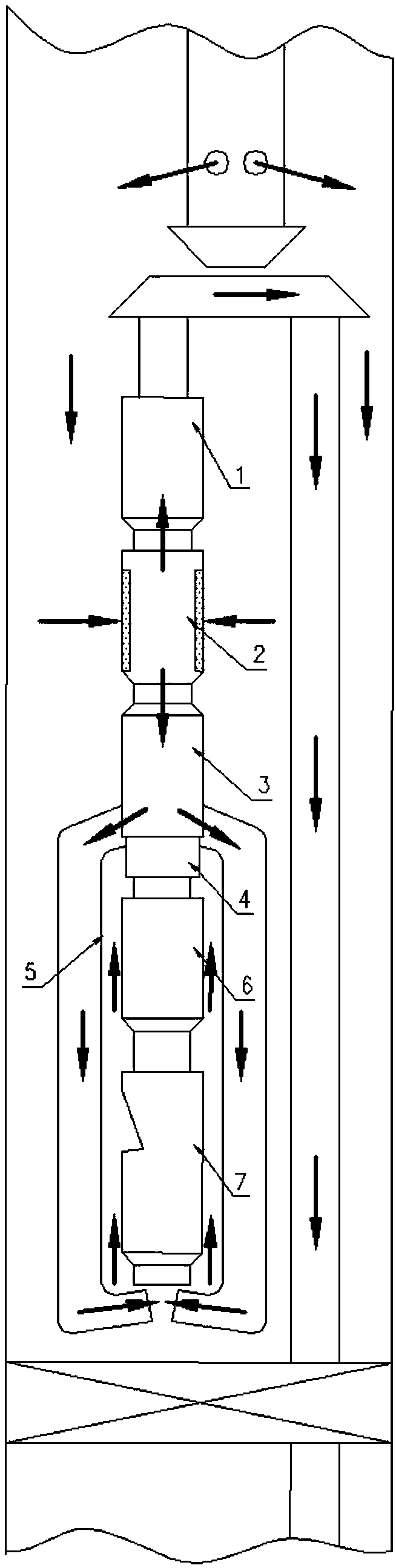

[0018] Such as figure 1 As shown, this embodiment discloses a cooling device for downhole submersible motors, which mainly includes a water injection pump 1, a pump suction port 2, a cooling pump 3, a sealing joint 4, and a flow guide tube 5 connected sequentially from top to bottom , protector 6, motor 7. Among them, the water injection pump 1, the pump suction port 2, the protector 6, and the motor 7 are the existing components of the traditional submersible pump unit. The well fluid injected by the water injection casing of the layered injection process enters the sealing annulus where the unit is located through the holes on the pipe string. When the liquid level reaches the vicinity of the pump suction port 2, the liquid will be pumped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com