Formula milk quick measuring and blending device

A technology for infants and milk powder, applied in applications, home appliances, kitchen appliances, etc., can solve the problems of long waiting time for babies crying and complicated milk powder extraction, so as to reduce the waiting time for crying, avoid nutrition loss, and prevent moisture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

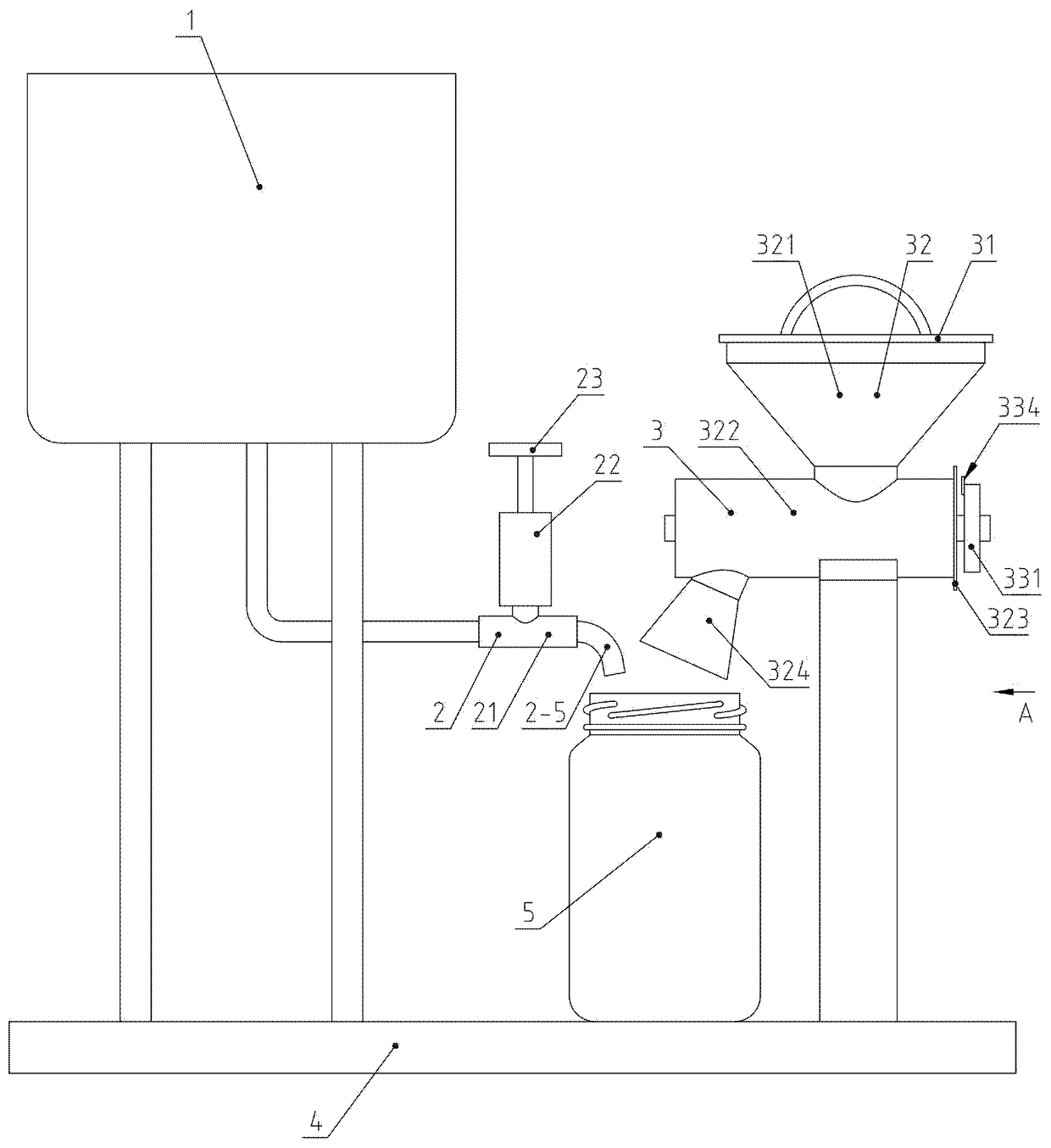

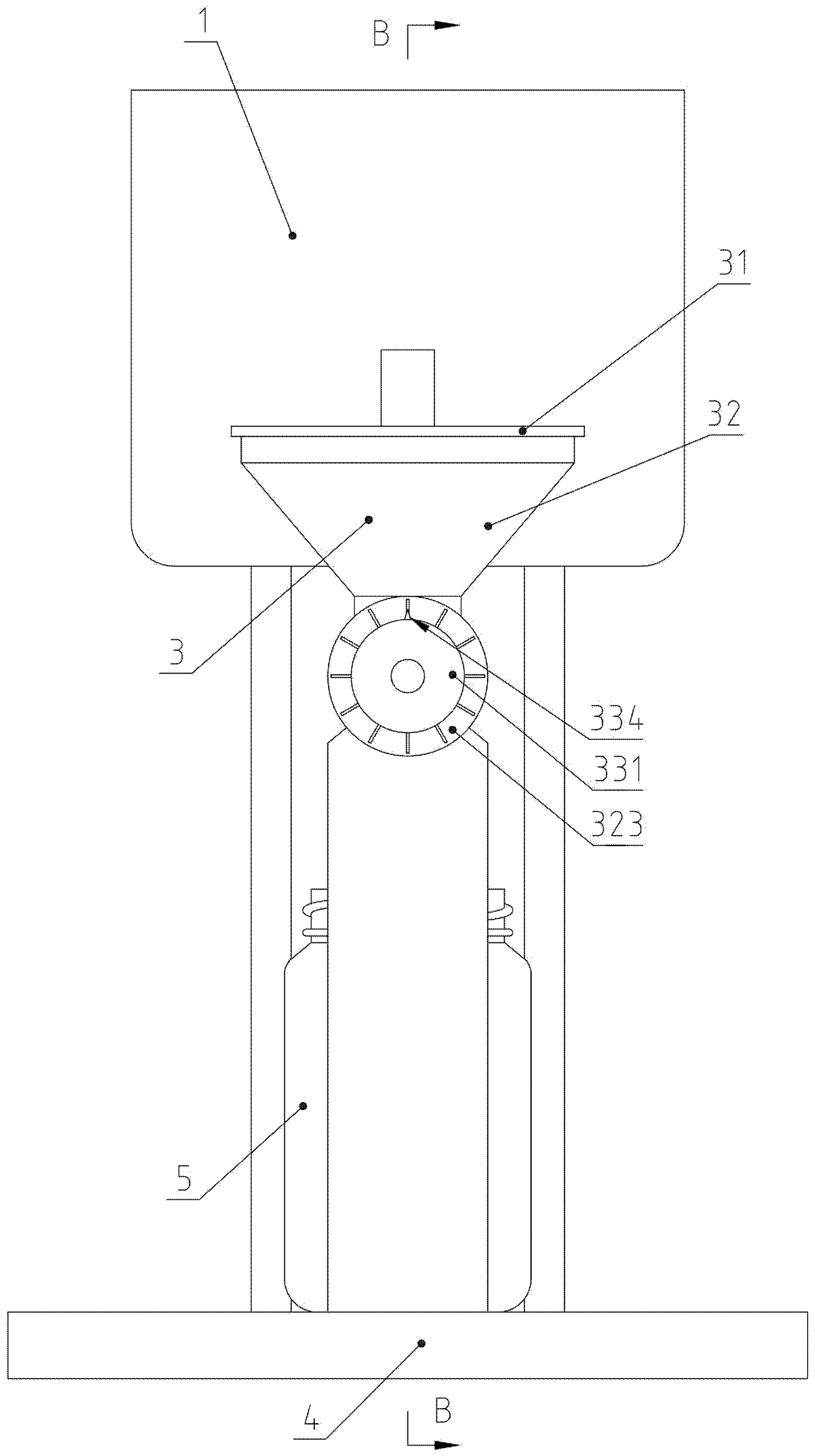

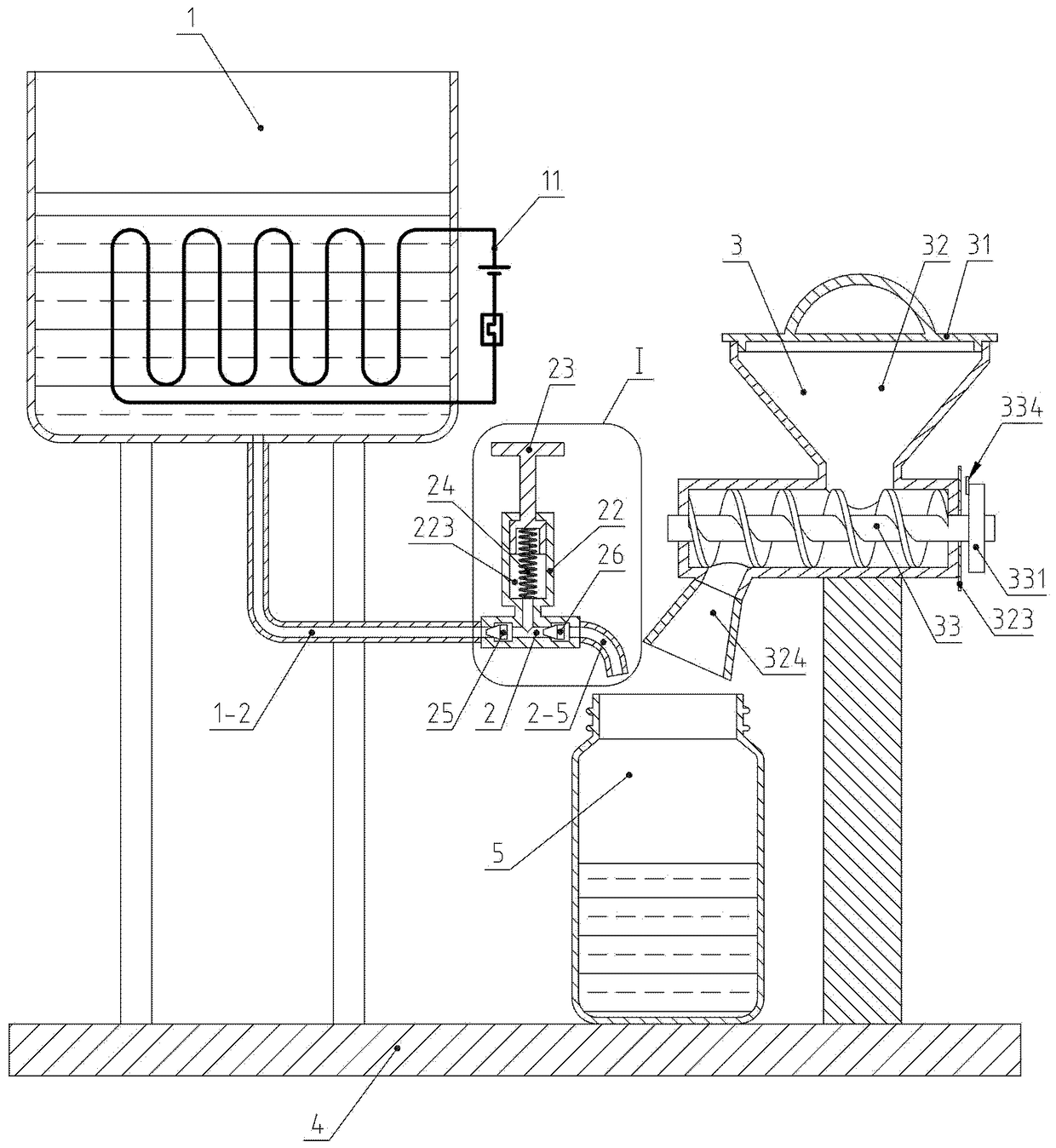

[0035] Example: see Figure 1 to Figure 8 .

[0036]A rapid metering and blending device for milk powder liquid for infants, comprising a constant temperature water tank 1, a quantitative water feeder 2, a quantitative milk powder feeder 3, a base 4, a water inlet elbow 2-5, and a water conduit 1-2;

[0037] The constant temperature water tank 1 is the same as the constant temperature milk water tank widely used in the market, including the constant temperature control system 11, which can keep the warm boiled water at a basically constant set temperature. Then the constant temperature of the constant temperature water tank 1 is set at 43 degrees, and the water in the constant temperature water tank 1 is kept at this temperature for standby; the constant temperature water tank 1 is fixedly connected with the base 4;

[0038] Quantitative water feeder 2 comprises one-way pipe 21, driving cylinder, water inlet cone plug 25 and water outlet cone plug 26; There are five sections ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com