Solid-liquid dual-purpose electrode material demagnetizing and crushing device

A technology of electrode materials and crushing devices, which is applied in the field of dual-purpose demagnetization and crushing devices for solid-liquid electrode materials, can solve problems such as low efficiency, hidden dangers of lithium battery safety performance, and lack of demagnetization functions, and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

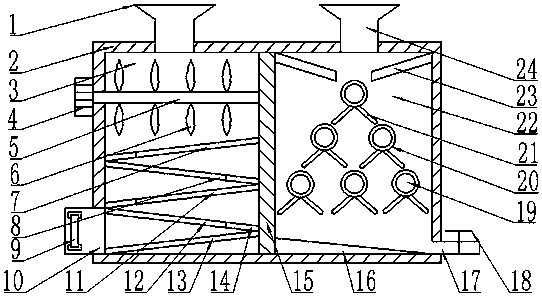

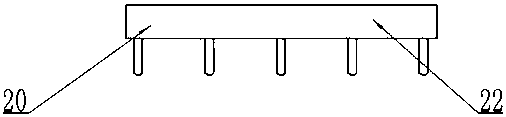

[0019] see Figure 1-2 , the present embodiment provides a dual-purpose demagnetization crushing device for solid-liquid electrode materials, including a box body 2; the box body 2 includes a solid demagnetization chamber 3, an intermediate partition 15 and a liquid demagnetization chamber 22; the solid The demagnetization chamber 3 is provided with a graphite feed hopper 1, a crushing device, a demagnetization device and a box door 10; the graphite feed hopper 1 is arranged at the upper end of the solid demagnetization chamber 3; the crushing device includes a driving motor 4 and a rotating shaft 5; the drive motor 4 is arranged at the left end of the casing 2, and the drive motor 4 is connected to the rotating shaft 5; the rotating shaft 5 runs through the left end wall of the casing 2, and the rotating shaft 5 is provided with a crushing blade 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com