Building rubbish recycling device

A technology for construction waste and movable installation, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of spending a lot of energy on transportation and cleaning, limited service life of concrete, and refractory construction waste, and achieves a simple structure, The effect of avoiding secondary pollution and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

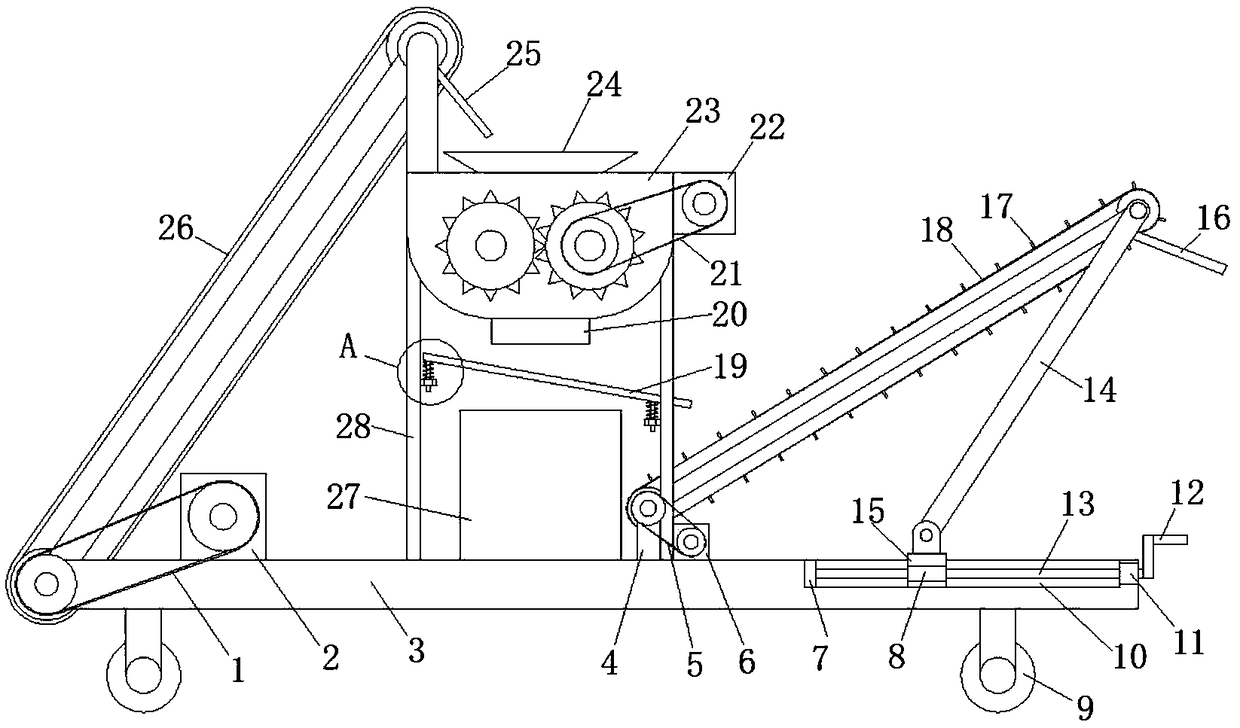

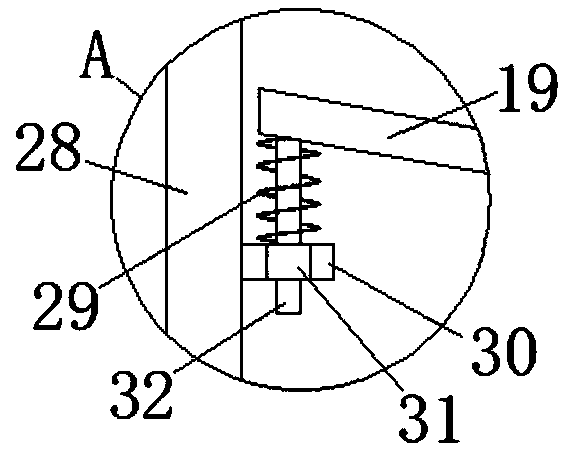

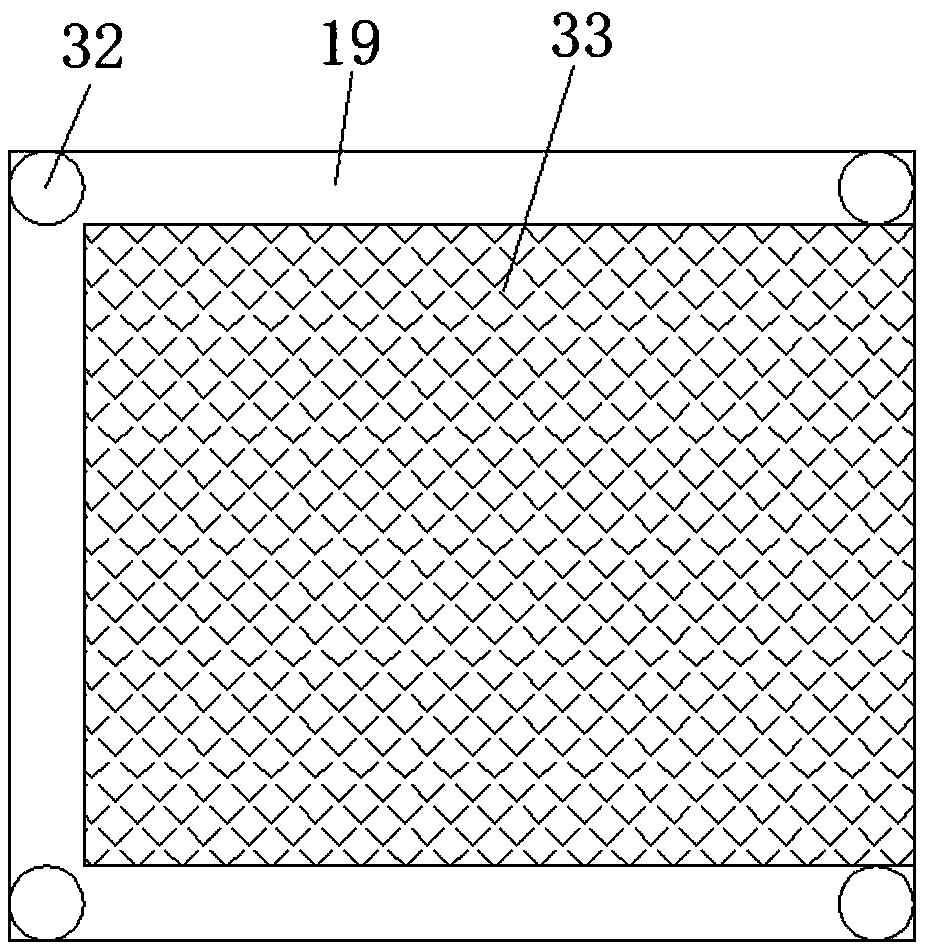

[0020] according to Figure 1-3 The construction waste recycling device shown includes a bottom plate 3, a feeding mechanism 26, a crushing box 23 and a feeding mechanism 18. The four corners of the bottom of the bottom plate 3 are equipped with braked rollers 9, and the crushing box 23 is supported by four Leg 28 is installed on the upper middle part of base plate 3, feeding mechanism 26 is installed on the side of base plate 3 close to crushing box 23, and feeding mechanism 18 is installed on the other side of base plate 3 close to crushing box 23, and the top of breaking box 23 is provided with The feed port 24, the lower part of the crushing box 23 is provided with a discharge po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com