Rotating device used for machining of tubular materials and facilitating fixing

A rotating device and material processing technology, which is applied in the direction of positioning device, workpiece clamping device, clamping device, etc., can solve the problems of inconvenient position changes of tubular materials and affect the processing efficiency of tubular materials, etc., and achieve flexible and changeable fixed forms. Novel, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

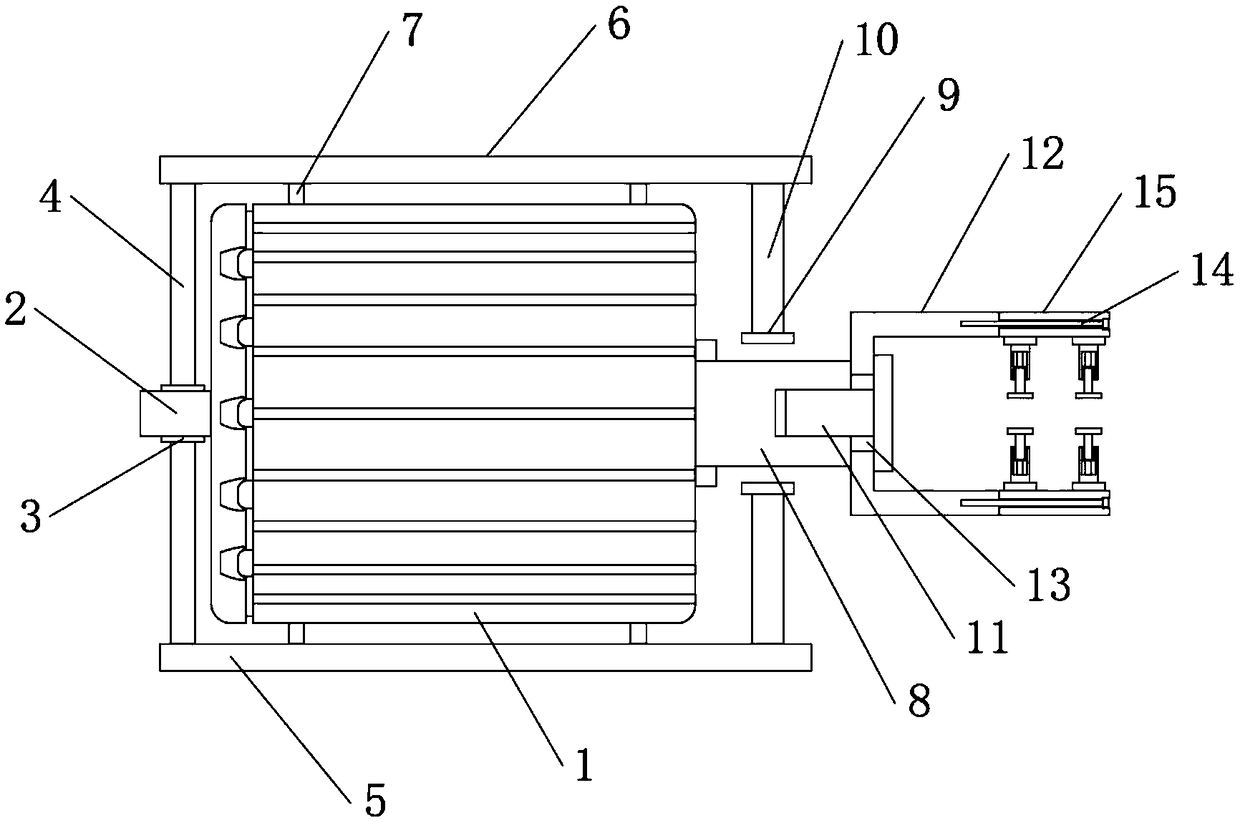

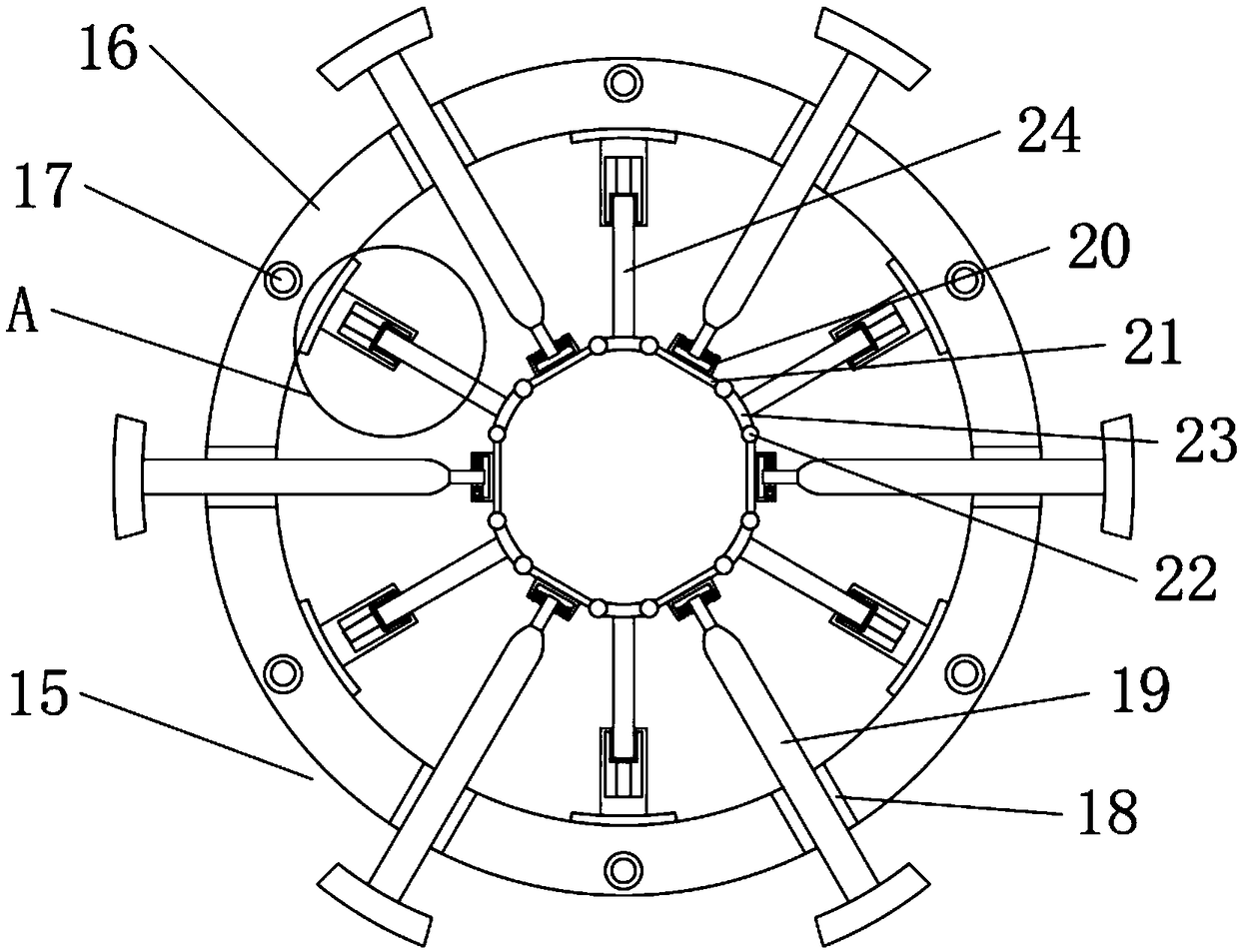

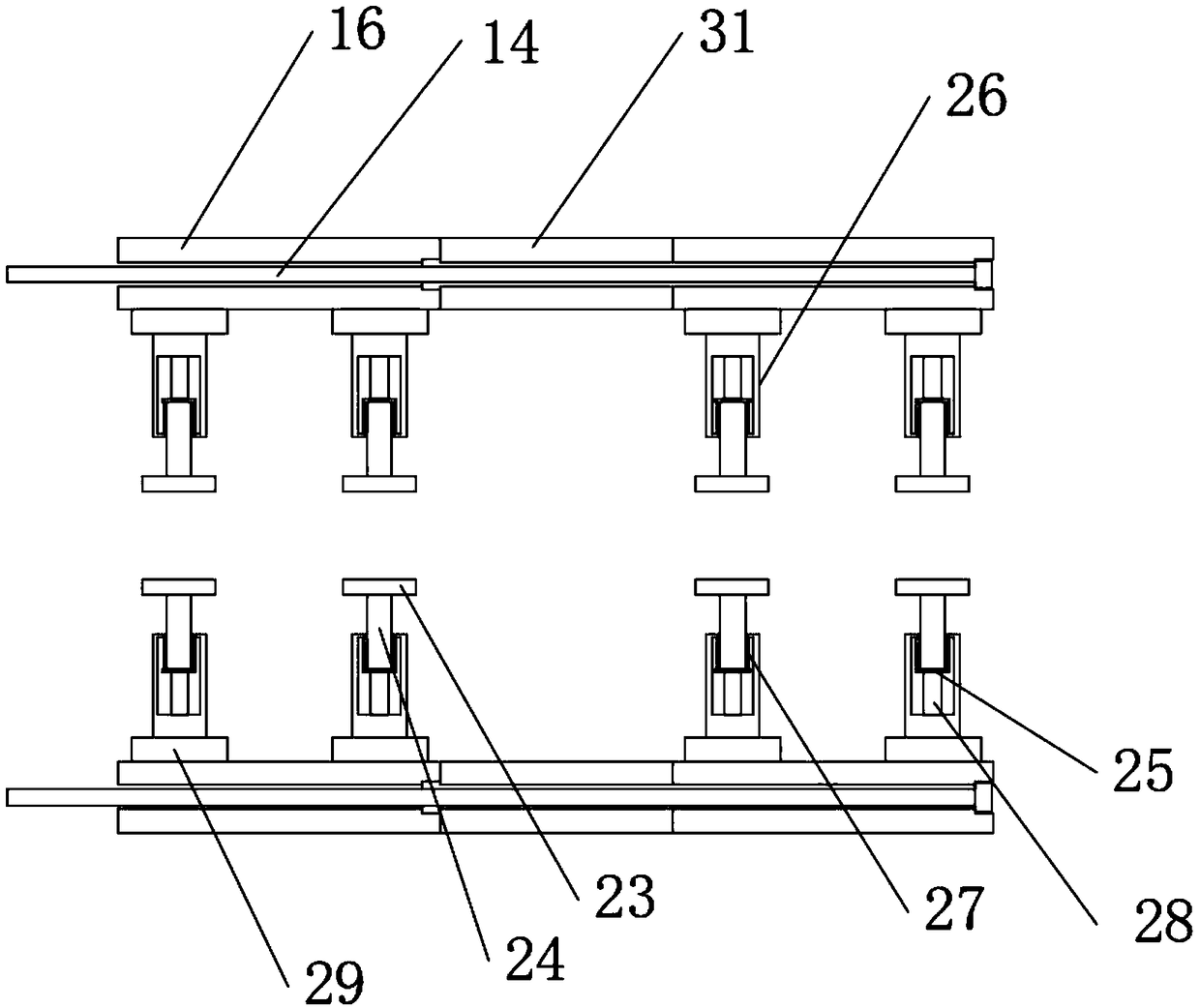

[0022] like Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a conveniently fixed rotating device for processing tubular materials, including a core motor 1, and the end of the core motor 1 away from the output end is fixedly connected with a core motor limiting plate 2, the The upper and lower panels of the core motor limiting plate 2 are in contact with the limiting plate backing plate 3, and the side panel of the limiting plate backing plate 3 far away from the core motor limiting plate 2 is vertically connected to the core motor limiting core motor limiting Pressing plate 4, the core motor limiting core motor limiting pressing plate 4 is connected to a core motor base plate 5 and a core motor top guard plate 6 respectively on one side away from the limiting plate backing plate 3, and the core motor base plate 5 is set Below the core motor 1, the core motor top guard plate 6 is arranged above the core motor 1, and the core motor base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com