Designing and manufacturing method for personalized precise implantation of micro-implant anchorage

A production method and micro-implantation technology, which are applied in dental implants, medical science, dentistry, etc., to achieve the effect of repeatability, good controllability, and reduction of technical difficulty and processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] DRAWINGS Examples and embodiments of the present invention will be described in further detail.

[0053] A micro planting design method of manufacturing a personalized orthodontic precise implant, the method comprising the steps of:

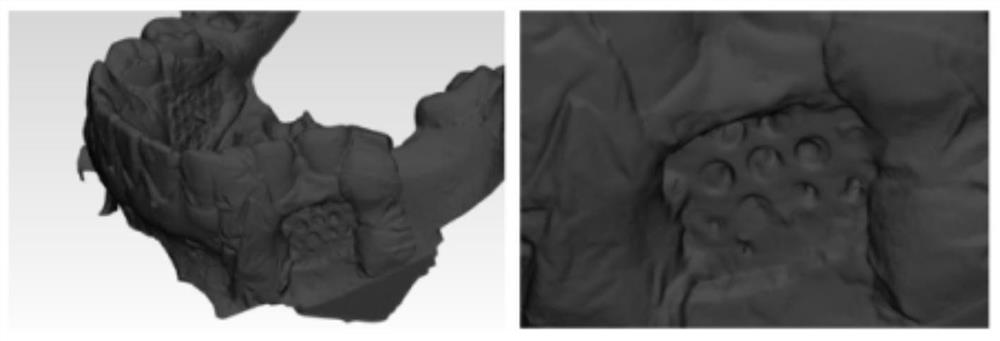

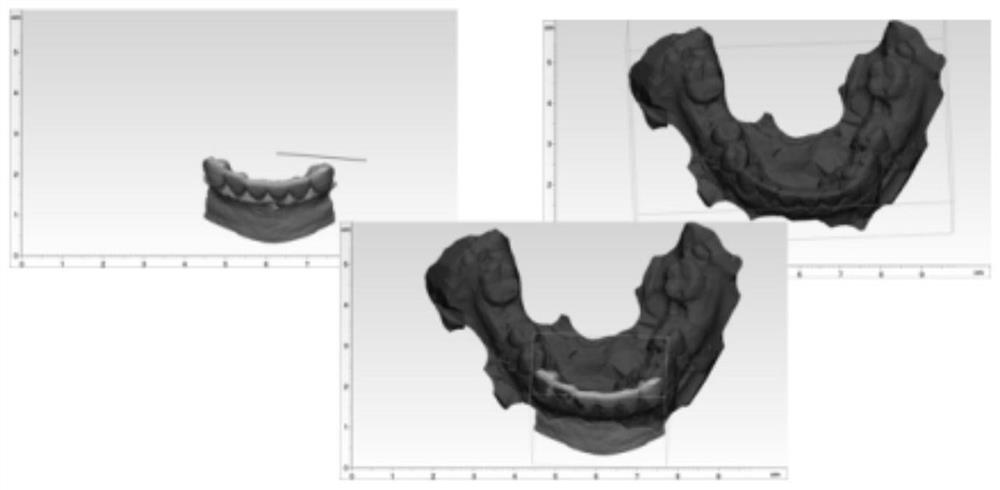

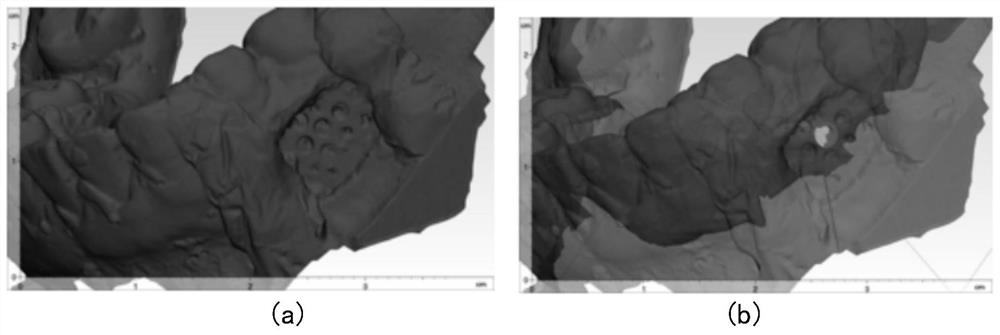

[0054] 1) produced with a positioning grid and scanning marks Model

[0055]Bidirectional positioning grid 1.1) Preparation of the patient after the upper or lower jaw impression, a plaster model at the time of filling, with a three-dimensional attributes embedded in the alveolar bone or the implant region and the corresponding sides of the base model to be implanted region the other side of the seat, which was named implanted side and the auxiliary side positioning; 1.2) infusion plaster impression coagulation, fully exposed surface mesh; 1.3) using a model or oral scanners scanning, 3D reconstruction of the model data mark is formed; like figure 1 Indicated.

[0056] 2) Model marker CBCT 3D reconstruction data registration mandible

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com